Control device for internal combustion engine

A technology of a control device and an internal combustion engine, used in engine control, internal combustion piston engines, combustion engines, etc., can solve problems such as torque fluctuation, misfire, and unstable exhaust gas volume, and achieve the effect of suppressing exhaust gas deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

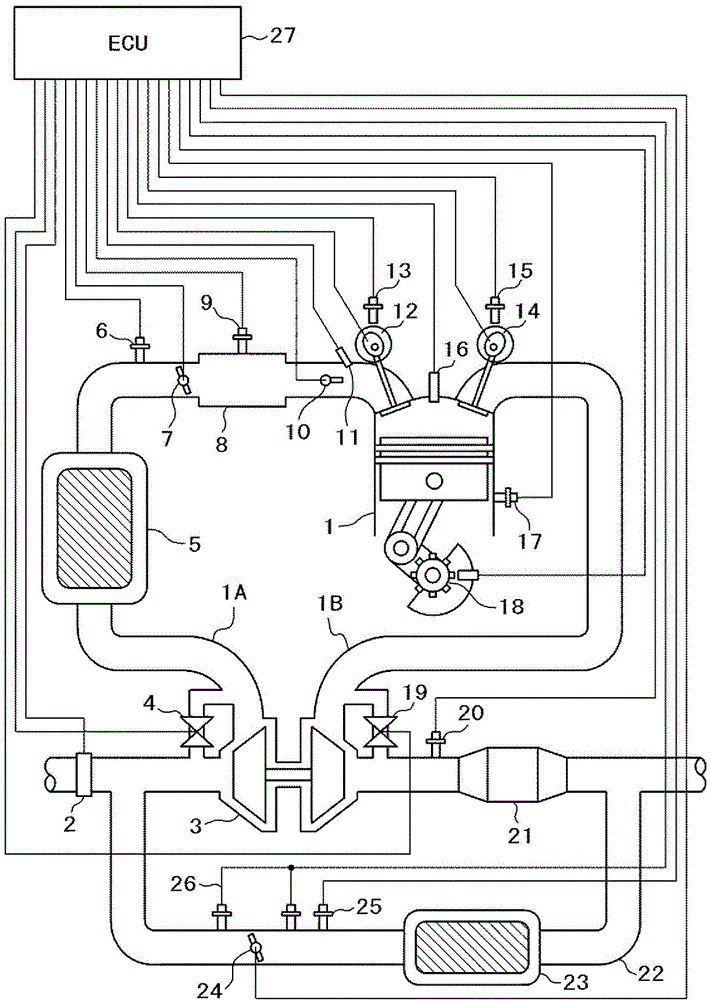

[0043] exist figure 1 Among them, reference numeral 1 is an internal combustion engine to be controlled, and the internal combustion engine 1 communicates with an intake flow path 1A and an exhaust flow path 1B.

[0044] An air flow sensor 2 including an intake air temperature sensor is incorporated in the intake air flow path 1A. A turbocharger 3 is arranged in the intake flow path 1A and the exhaust flow path 1B. The compressor of the supercharger 3 is connected to the intake flow path 1A, and the turbine is connected to the exhaust flow path 1B.

[0045] The supercharger 3 includes: a turbine for converting energy of exhaust gas into rotational motion of turbine blades; and a compressor for compressing intake air by rotation of compressor blades coupled to the turbine blades. An intercooler 5 for cooling the temperature of the intake air which has been raised by adiabatic compression is provided downstream of the compressor side of the supercharger 3 .

[0046] An intake ...

Embodiment 2

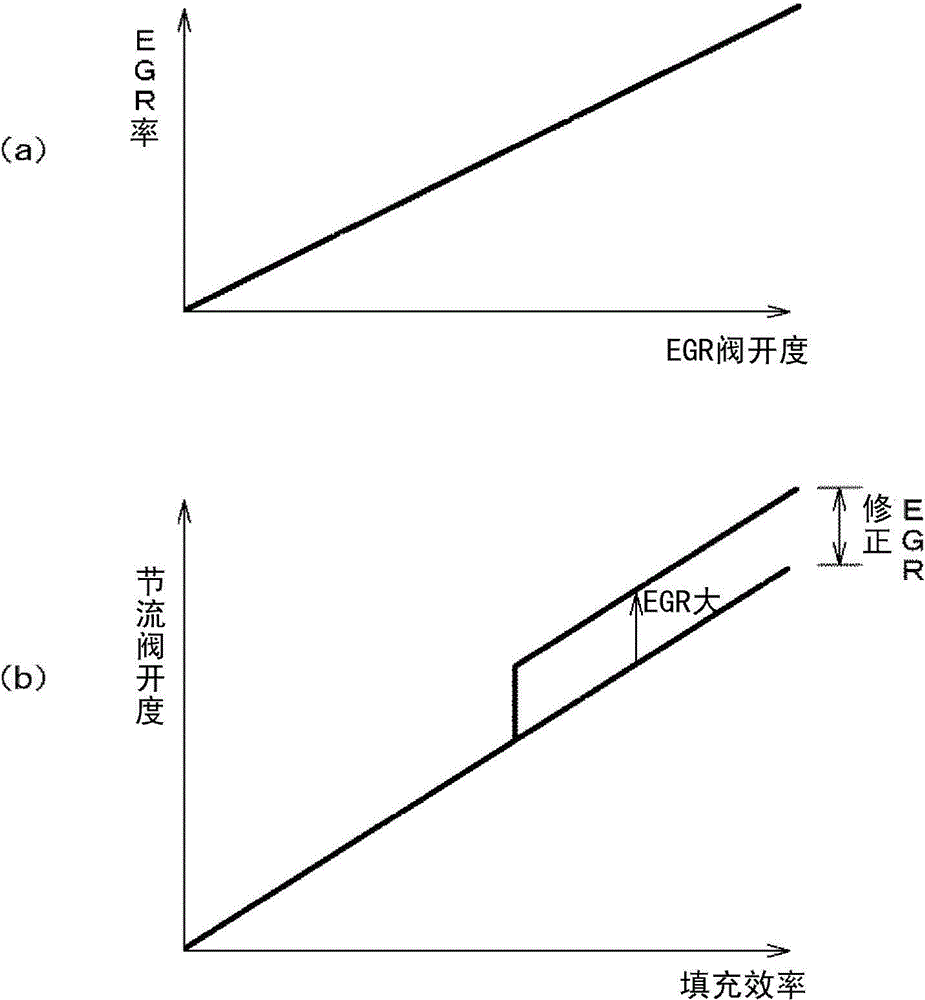

[0141] In the first embodiment described above, the angle of action of the intake valve 12, the so-called lift amount, is changed in order to control the intake amount. In contrast to this, in other embodiments described below, the use of the throttle valve 7 is shown. to control the volume of inhalation.

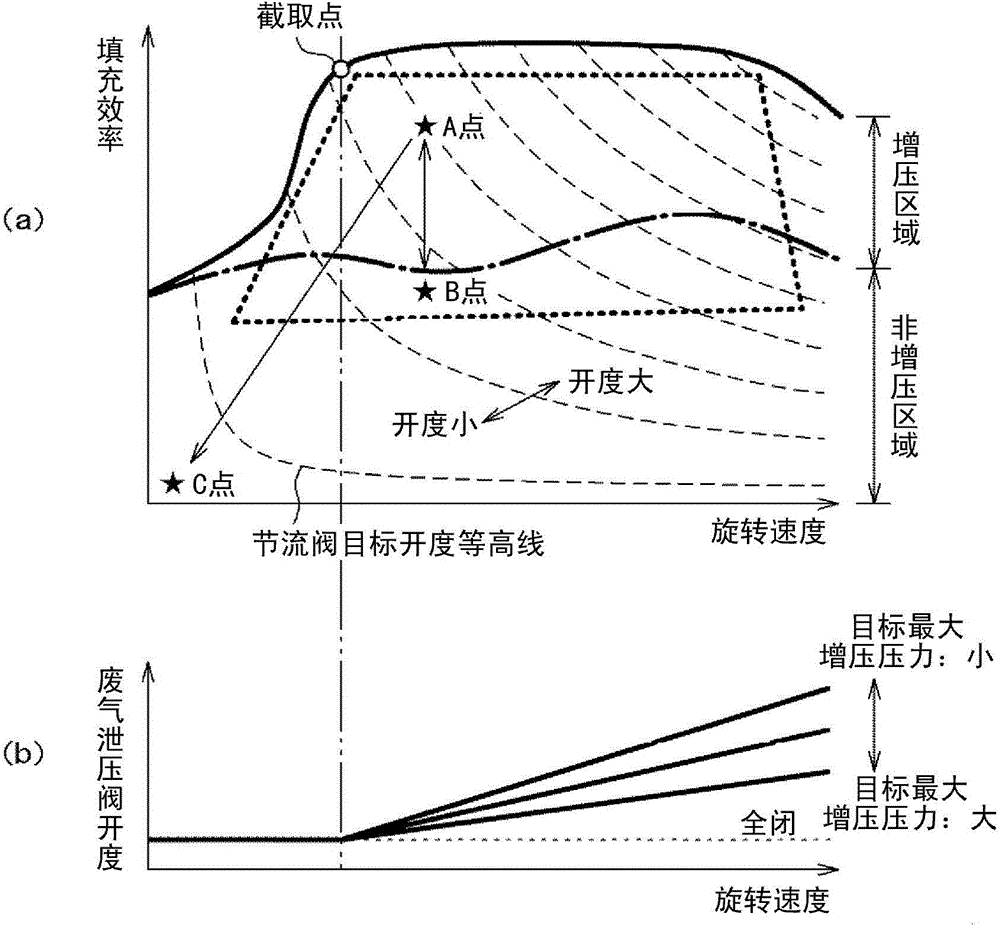

[0142] Figure 18 It is a diagram explaining the correspondence relationship between the throttle valve 7 and the wastegate valve 19 in the steady-state target opening degrees in an internal combustion engine including a supercharger.

[0143] Figure 18 (a) shows the corresponding relationship of the steady-state target opening degree of the throttle valve 7. In the non-supercharged region, the opening degree of the throttle valve 7 increases with the increase of the intake air amount. On the other hand, in the supercharged region, the opening degree of the throttle valve 7 In the region, the throttle valve 7 is fully opened to perform load control based on the superchar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com