Corrosion-resistant washer, and secondary battery comprising same

A secondary battery, corrosion-inhibiting technology, used in small-sized batteries/battery packs, battery pack parts, battery boxes/jackets, etc. The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

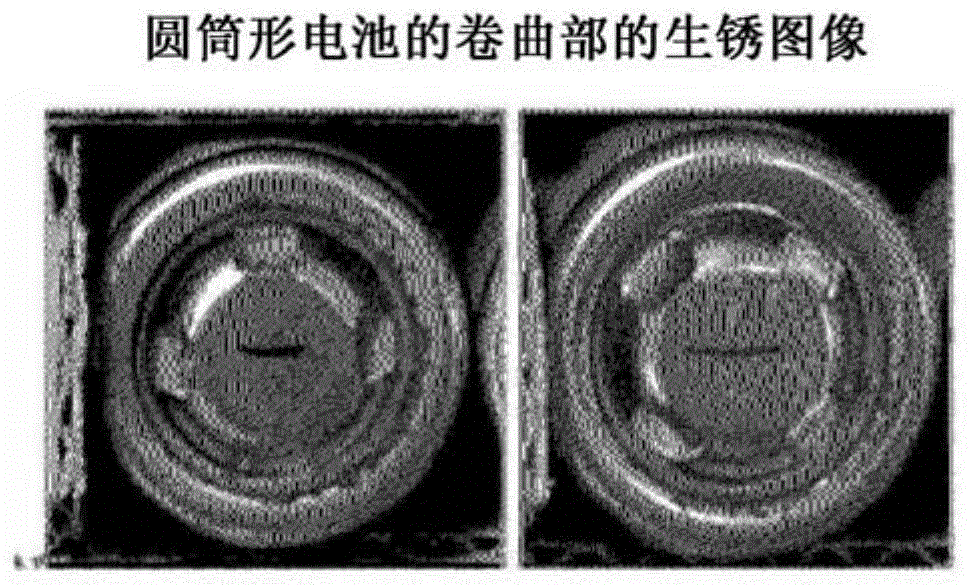

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066]

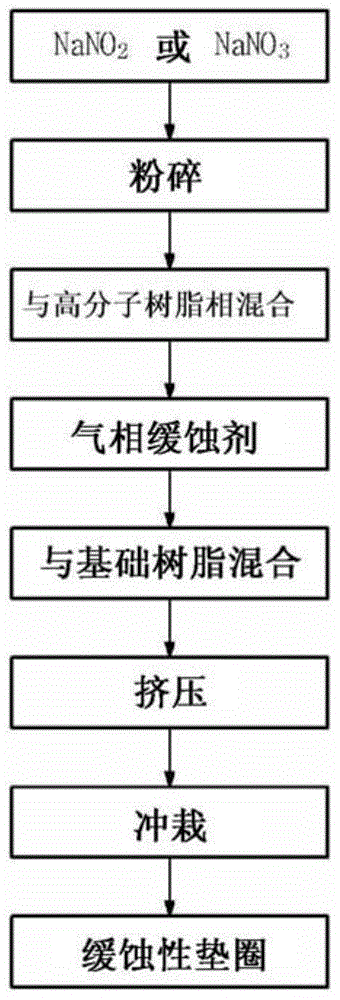

[0067] Under normal temperature and pressure conditions, the NaNO 2 After being uniformly mixed, pulverization is uniformly performed until a uniform shape is obtained. The above NaNO that will be pulverized 2 Mixed with molten polypropylene resin to obtain a vapor phase corrosion inhibitor (VCI).

[0068] Then, after granulating the gas-phase corrosion inhibitor, the gas-phase corrosion inhibitor in particle form was obtained by cooling to normal temperature. Mix the thus-obtained granular gas-phase corrosion inhibitor with polypropylene resin as the base resin at a ratio of about 0.5:10, and extrude at a specified temperature to obtain an extruded sheet, and punch the above-mentioned extruded sheet using a die Planted in the shape of a washer, a corrosion-inhibiting washer is manufactured.

[0069]

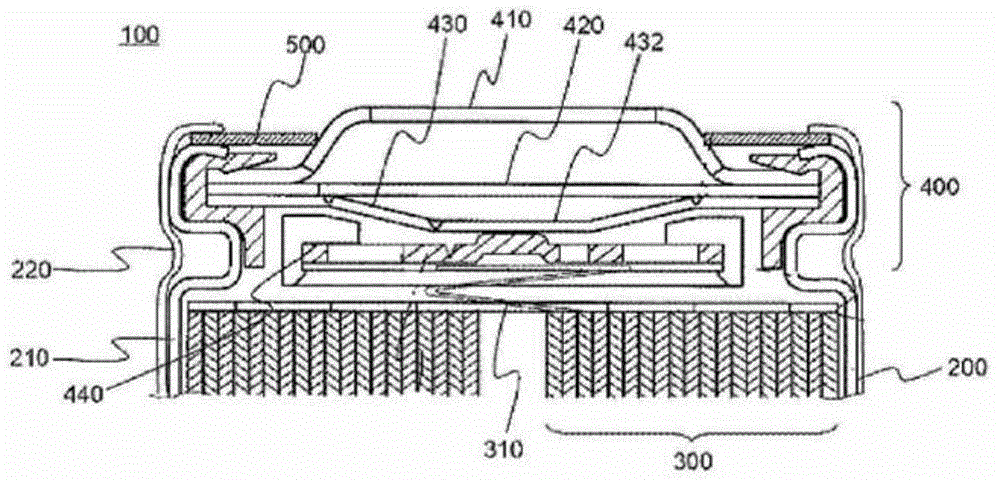

[0070] After manufacturing the upper end cap and cylindrical can using Ni-plated SPCE (cold-rolled steel plate), and installing the electrode assembly in the cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com