Method for manufacturing a battery, battery arrangement and modular system

A battery module and modular technology, applied in the field of manufacturing batteries, can solve the problems of high cost, negative cost and cost, and high cost, and achieve the effects of reducing R&D cost and manufacturing cost, simple cost and low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

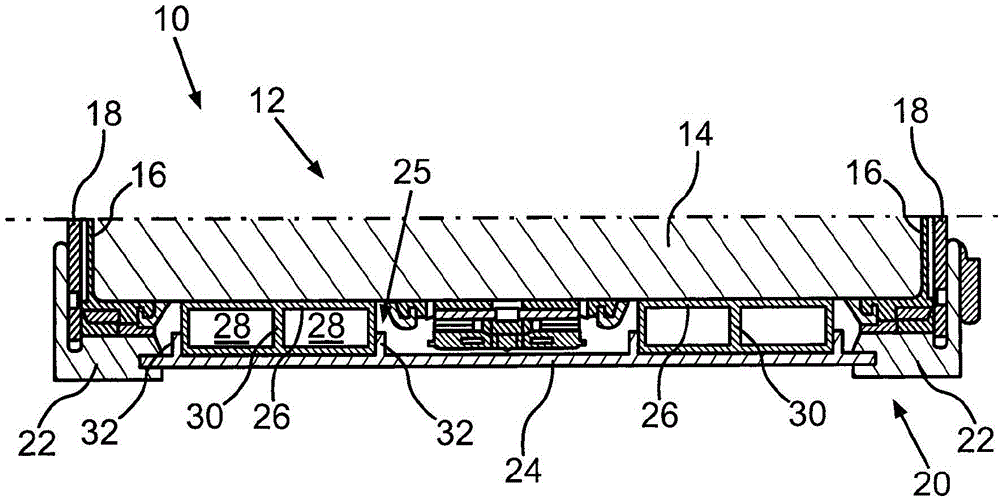

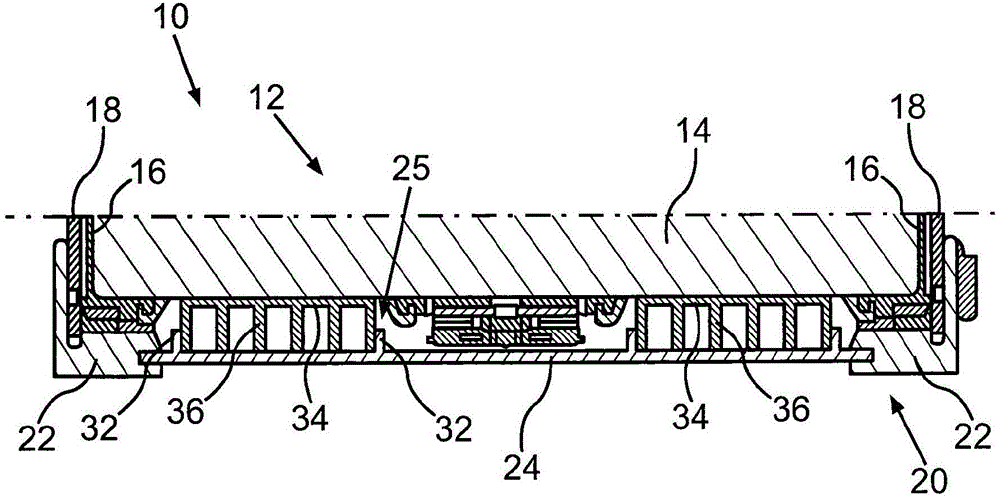

[0045] exist figure 1 A battery module 12 is shown in section from a battery 10 , which may in particular be designed as a vehicle battery, and which comprises a plurality of battery cells 14 . The battery cells 14 are electrically insulated from one another by so-called separators or separators 16 . The battery modules 12 are delimited laterally by corresponding side panels 18 , which are also referred to as connectors / binders. The side panels 18 fix the spacers 16 relative to each other and connect the (not shown here) end panels of the battery modules 12 to one another, which end panels close the battery modules 12 towards their end sides.

[0046] The battery 10 also comprises a support device 20 comprising two rails 22 of L-shaped cross-section, preferably formed as extruded profiles made of aluminum alloy. Rails 22 arranged at the respective corner regions of the battery modules 12 support the battery modules 12 from below and frame the battery modules 12 at the sides....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com