Special large cutter grinder for bearing cutter

A knife grinder and cutting tool technology, which is applied in the direction of grinding machine parts, manufacturing tools, grinding drive devices, etc., can solve the problems of low machining accuracy, complicated operation, poor consistency, etc., and achieve high processing efficiency and high product finish , good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

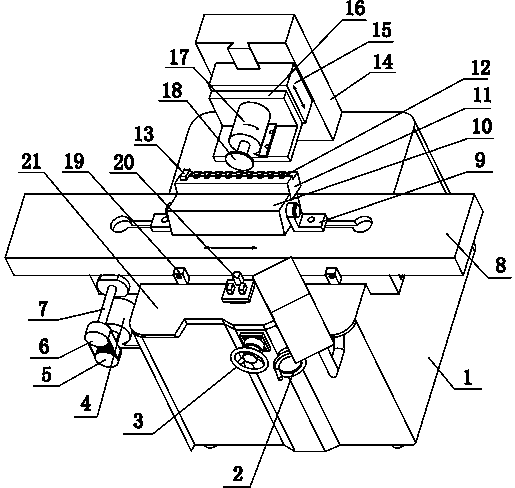

[0011] The present invention will be further explained below in conjunction with the drawings in the specification:

[0012] A large-scale sharpening machine for bearing tools, including machine tool 1. The machine tool 1 is equipped with a tool holder mounting seat moving mechanism and a grinding mechanism. The tool holder mounting seat moving mechanism includes a horizontal moving mechanism and a longitudinal moving mechanism. The longitudinal moving mechanism is mainly composed of a large The adjusting wheel 3, the driving screw and the longitudinal moving plate 21 are composed of the longitudinal moving plate 21 which moves longitudinally on the machine tool through the large adjusting wheel 3 and the driving screw. The horizontal moving mechanism is arranged on the longitudinal moving plate, and the horizontal moving mechanism is mainly composed of the horizontal The motor 4, the transverse feed shaft 7 and the transverse table 8 are composed. The transverse motor 4 is instal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap