Diverter for automobile sealing strip extrusion head

A technology of automobile sealing strip and extruder head, which is applied in the field of rubber extrusion equipment to achieve the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

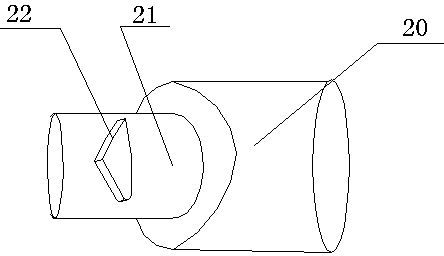

[0029] Please refer to figure 2 , figure 2 It is a structural schematic diagram of a diverter at the extrusion head of an automobile weather strip according to the present invention. The diverter is provided with a diverter body 20 , a groove 21 and a triangular protrusion 22 .

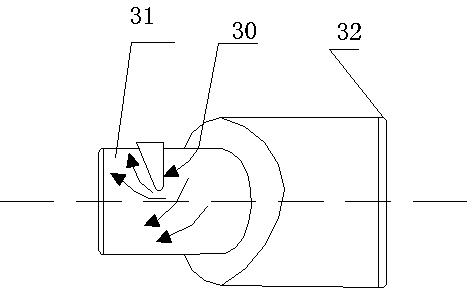

[0030] The shunt body 20 is cylindrical, and its two ends are provided with chamfers 32 (see image 3 ); the triangular protrusion 22 is located on the surface of the flow divider; the groove 21 includes a main flow channel group 30 that is bifurcated by two flow channels (see image 3 ) and the secondary runner group 31 which is divided into forked by the other two runners (see image 3 ), the sprue group 30 (see image 3 ) with secondary runner group 31 (see image 3 ) is Unicom.

[0031] Please refer to image 3 , image 3 It is a front view and a flow state diagram of a diverter at the extrusion head of an automobile sealing strip according to the present invention.

[0032] The main ch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap