Steam box

A steam box and steam technology, applied in the field of steam box, can solve problems affecting user experience, wasting heat, scalding users, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

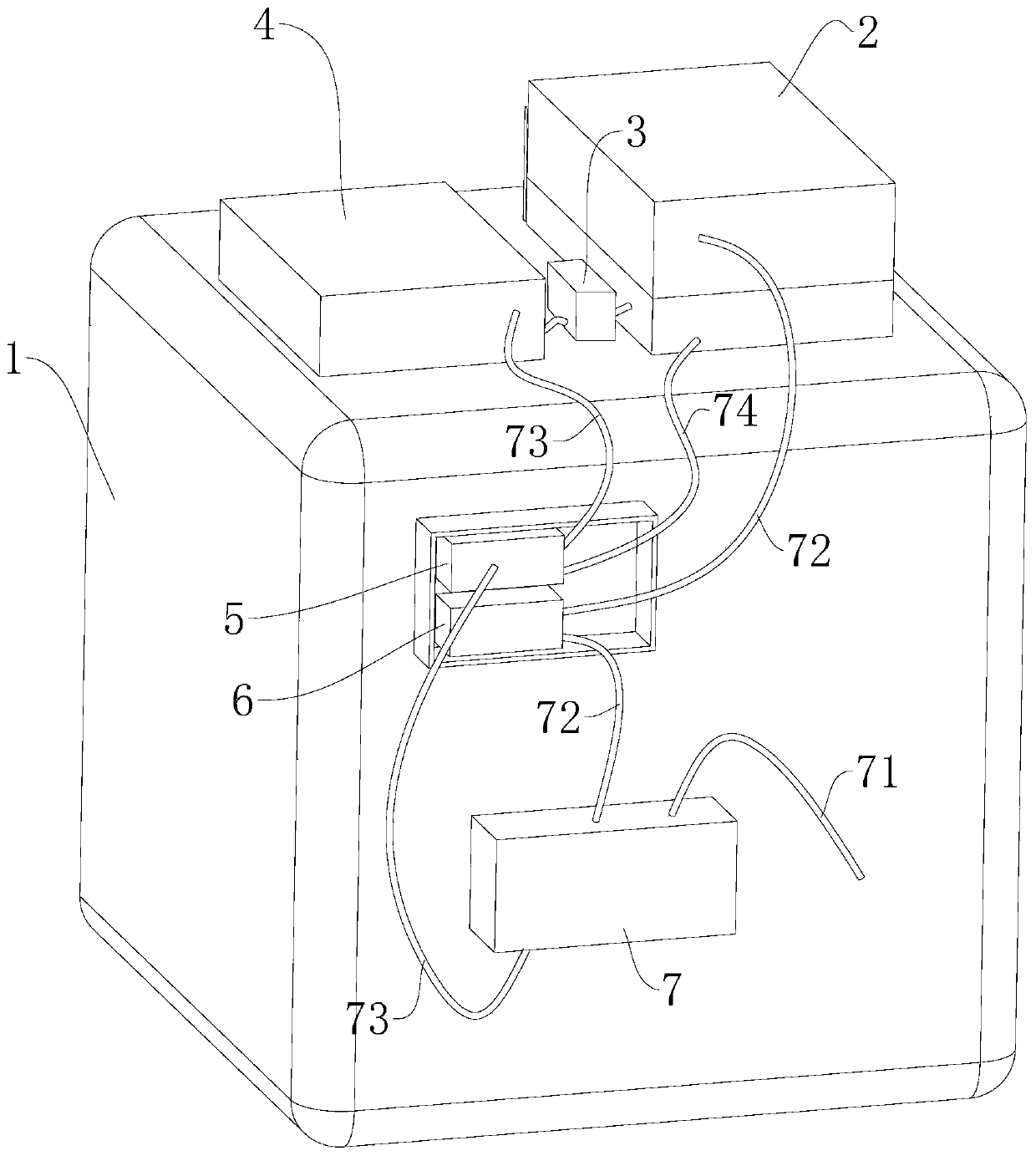

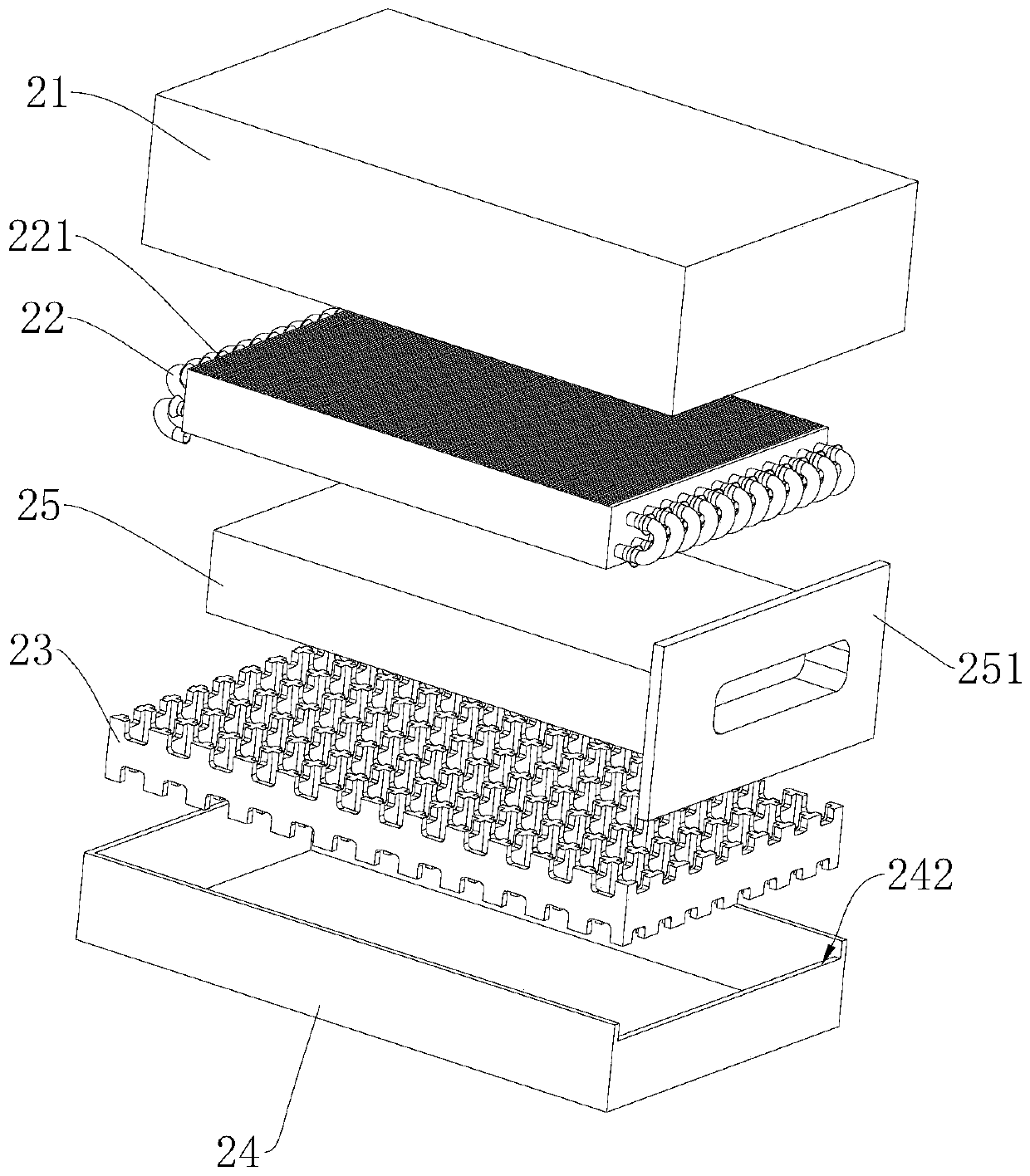

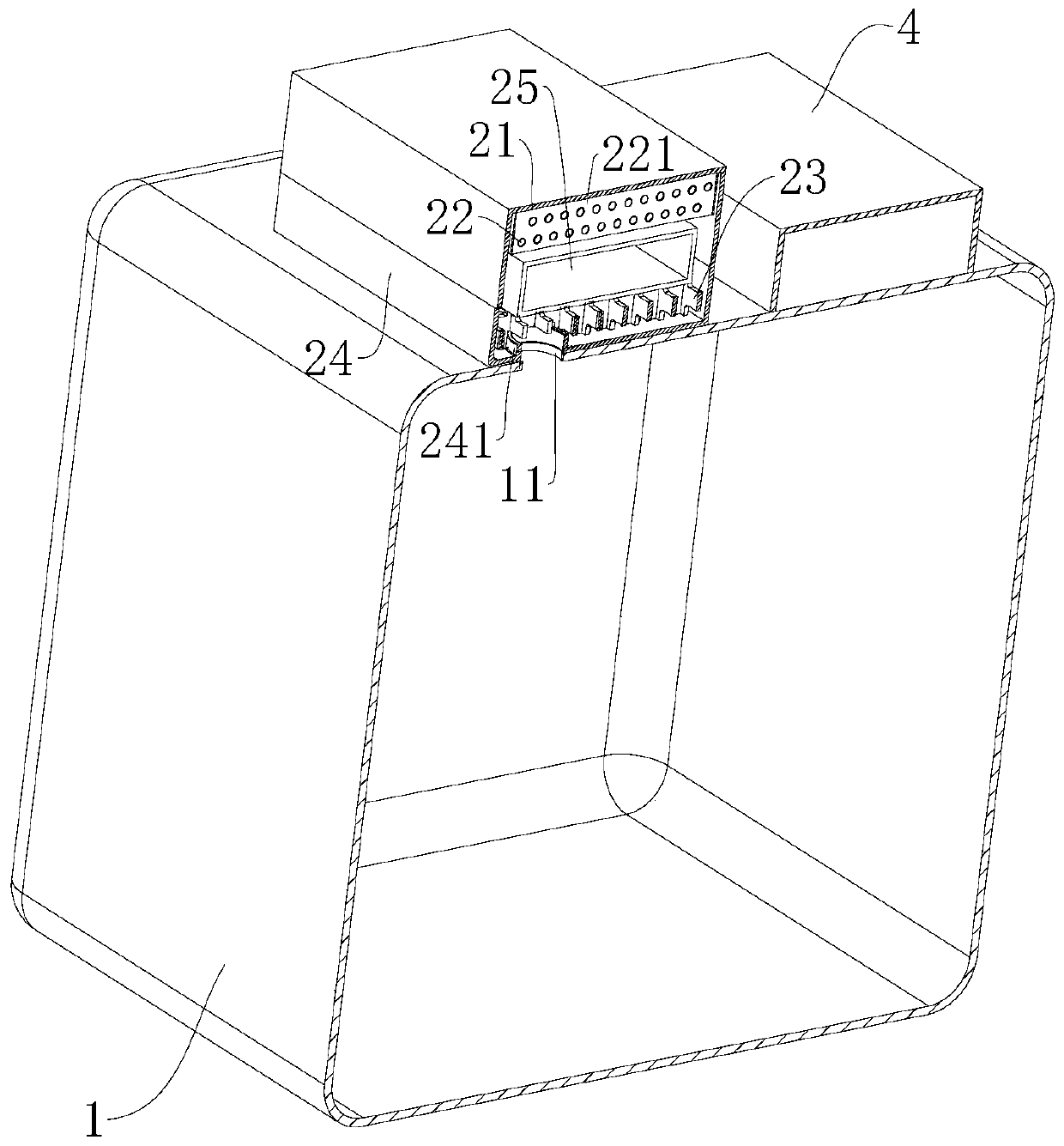

[0083] This embodiment provides a steam box, such as figure 1 As shown, it includes: an inner tank 1, including a steam through hole 11 arranged on the inner tank 1; a steam generator 7, communicated with the inner tank 1 through a first pipeline 71; a steam condensation chamber 2, connected to the inner tank 1 The steam through hole 11 is connected, and the steam condensing chamber 2 is provided with a condensing assembly. The steam generated by the steam generator 7 enters the inner container 1 through the first pipeline 71 , and the steam heats the food in the inner container 1 . The excess steam rises through the steam perforation hole 11 and enters the steam condensation chamber 2, so the steam is not easy to stay in the inner tank 1, and most of the steam enters the steam condensation chamber 2, and is affected by the condensation components to release heat and condense into liquid droplets and store in the steam In condensation chamber 2. Thereby preventing steam from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com