Waste engine oil propane extraction tower

A technology of extraction tower and oil propane, which is applied in the field of waste oil propane extraction tower to achieve the effects of slowing down fouling, strengthening heat exchange and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

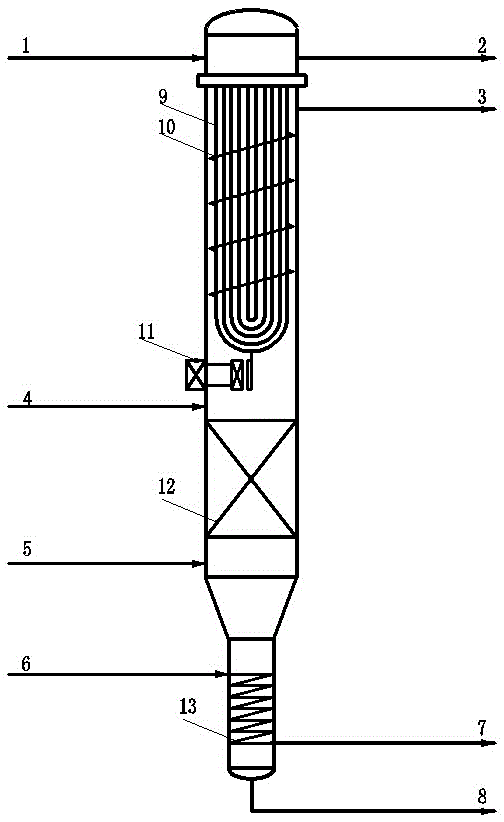

[0033] 4.6MPaG, 85℃, 36t / h waste engine oil 4 enters the middle of the extraction tower;

[0034] 4.6MPaG, 60℃, 110t / h propane 5 enters the lower part of the extraction tower;

[0035] Propane and waste engine oil are in countercurrent contact with the grid packing 12, the lubricating oil components in the waste engine oil are dissolved by propane, and a small amount of asphalt is also dissolved by propane to form an extract;

[0036] 0.4MPaG, 110°C, 125t / h hot water 1 enters the heat exchange tube bundle 9 at the upper part of the extraction tower, forming a temperature field of 87°C to 62°C in the upper part of the tower, and the hot water after heat exchange 2 The temperature drops to 94°C and flows out from the heat exchange tube bundle;

[0037] The extract liquid passes through the heat exchange tube bundle 9 and the spiral baffle plate 10 to exchange heat with hot water to raise the temperature, and the dissolved pitch is precipitated. Finally, the extract liquid 3 (pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com