Printer device

A technology for printers and relative configuration, applied to printing devices, printing, etc., which can solve problems such as rising costs of skew sensors, inability to detect paper, and skew sensor errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

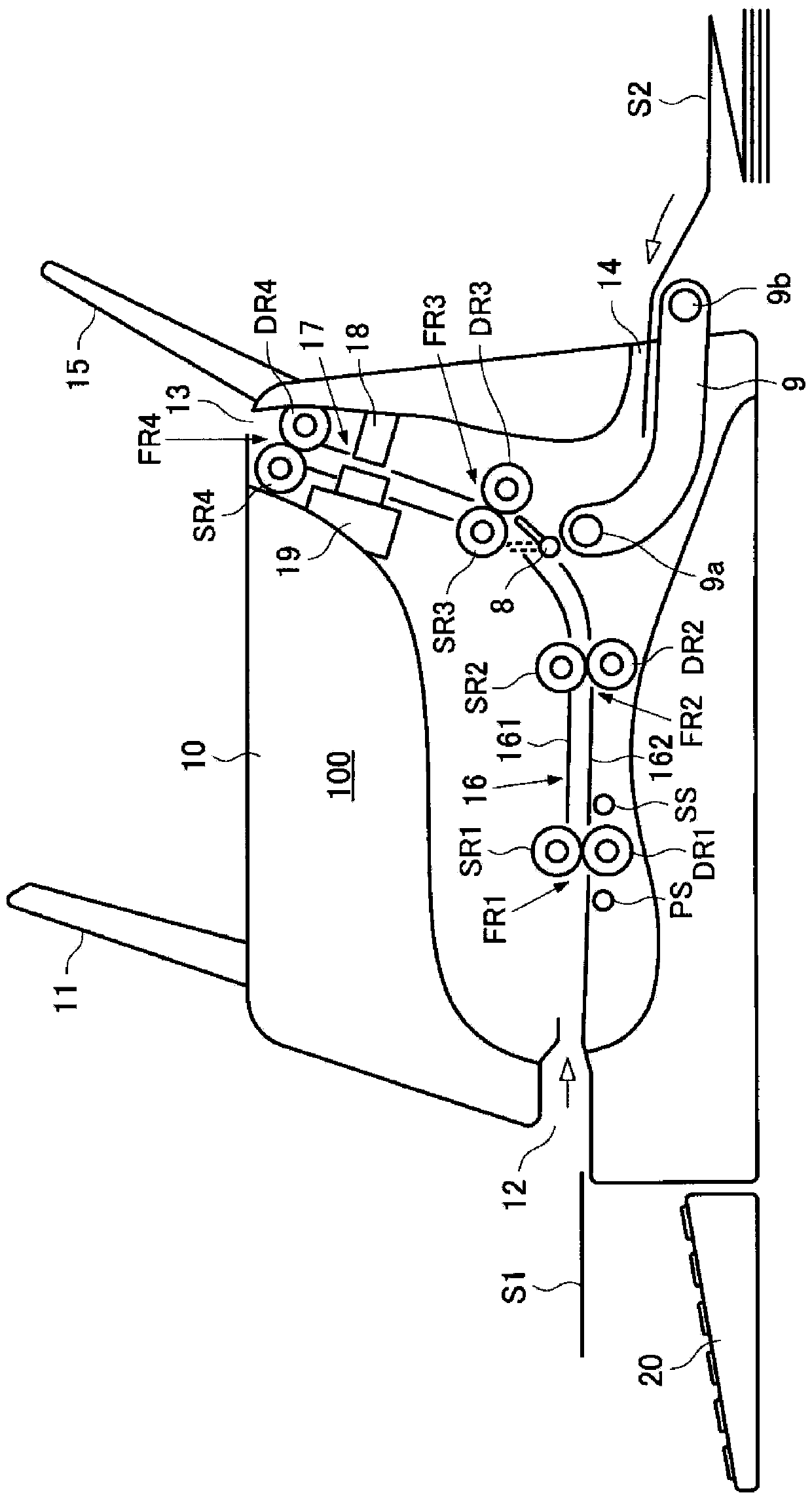

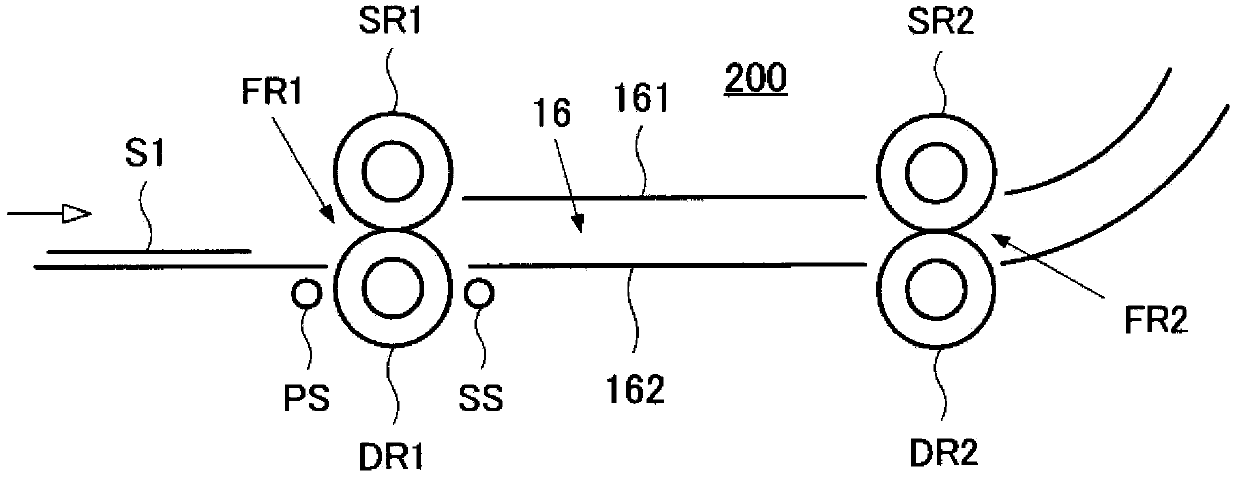

[0022] figure 1 shows the first embodiment related to the printer device, and figure 1 It is a side view showing a part of the case cut away. figure 1 Take the commercial machine 100 installed with a printer device as an example.

[0023] A display 11 is mounted on the front of the housing 10 . A keyboard 20 as an input device is disposed below the display 11 . In the area between the keyboard 20 and the display 11 of the housing 10, a paper feed port 12 for feeding the paper S1 is formed.

[0024] A paper discharge port 13 connected (communicated) with the paper feed port 12 is provided on the upper surface of the housing 10 . On the back side of the paper discharge port 13, a rear paper feed port 14 for supplying web-shaped continuous paper S2 is provided. Further, a paper discharge tray 15 is mounted on the upper surface of the housing 10 . The paper discharge tray 15 is located behind the paper discharge port 13 and holds the sheets S2 discharged from the paper discha...

no. 2 approach )

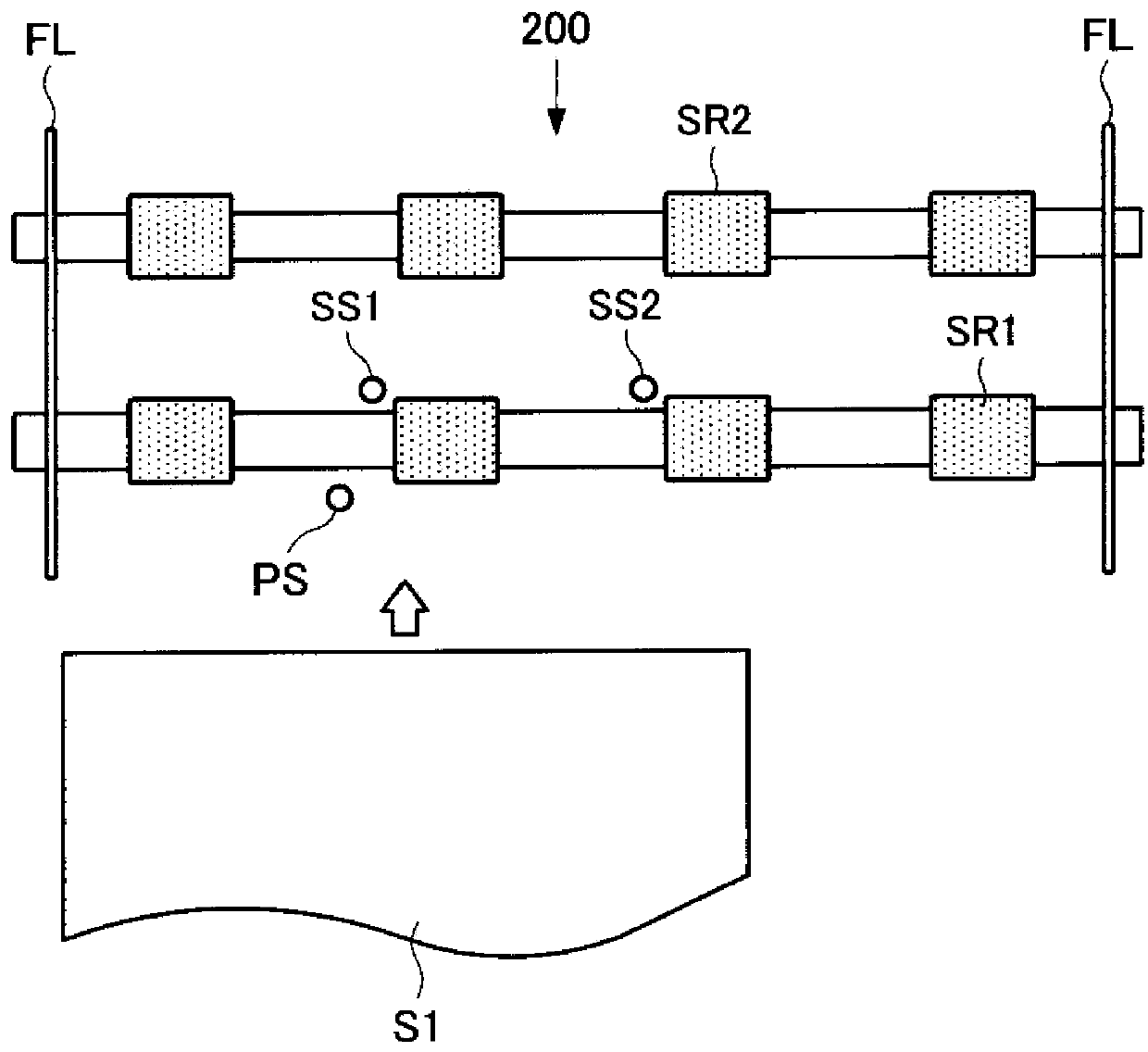

[0069] Figure 8 It is a figure explaining the 2nd Embodiment concerning a printer apparatus. In this embodiment, a third skew sensor SS3 capable of detecting narrow paper is provided downstream of the first skew sensor SS1 and the second skew sensor SS2 in the direction of the printer unit. Then, after the first skew sensor SS1 detects the paper S1, the conveyance of the paper S1 is continued, and the paper S1 is detected first by the second skew sensor SS2 or the third skew sensor SS3, and it is determined that the paper is a normal size paper. The skew error is still the feeding of paper with a narrow width size.

[0070] Below, combine Figure 9 The skew inspection according to this embodiment will be described along with the flow chart of FIG. Additionally, for Figure 7 The same processing is marked with the same symbol, and the description here is an explanation of different processing.

[0071] In Act 3 , the stepping motor 46 is continuously driven after the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com