Fully-automatic mechanical pencil lead and lead-replaceable fully-automatic pencil

A technology of fully automatic pencils and movement, applied in mechanical pencils, printing, writing utensils, etc., can solve the problems that hinder the development of fully automatic pencils, rely on labor, and cannot realize automatic assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

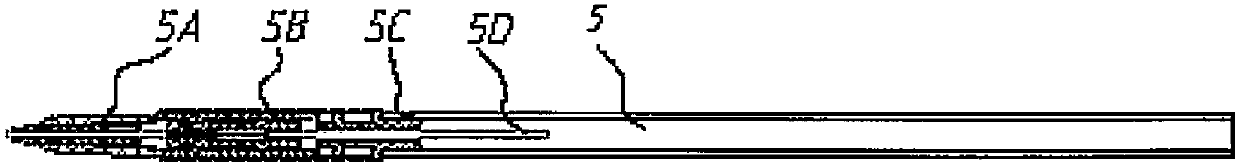

[0078] Such as Image 6 As shown, the full-automatic pencil in the present embodiment is a fixed type, which consists of a pen holder 2, a pen clip 1 located on the pen holder 2, a pen neck 3, a pen holder 4, and a full body fixedly installed in the pen holder 4 and the pen holder 3. The automatic pencil movement consists of 5 components.

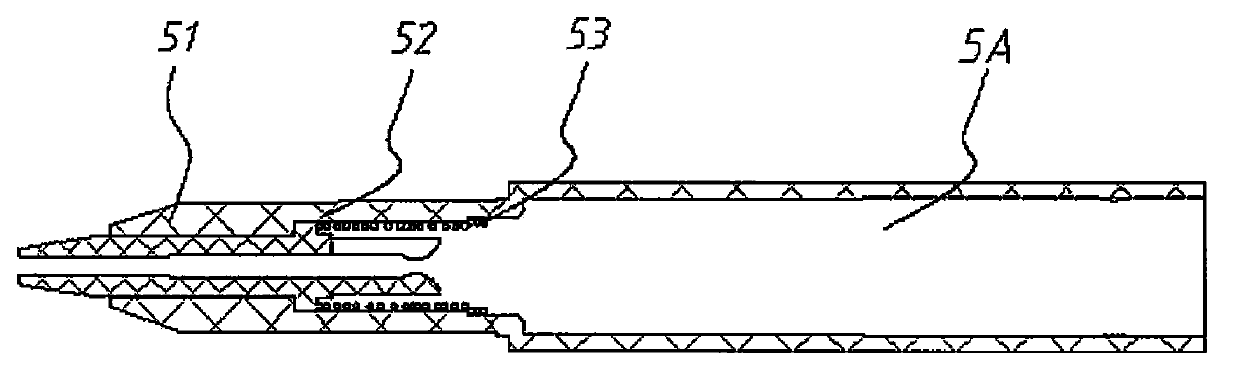

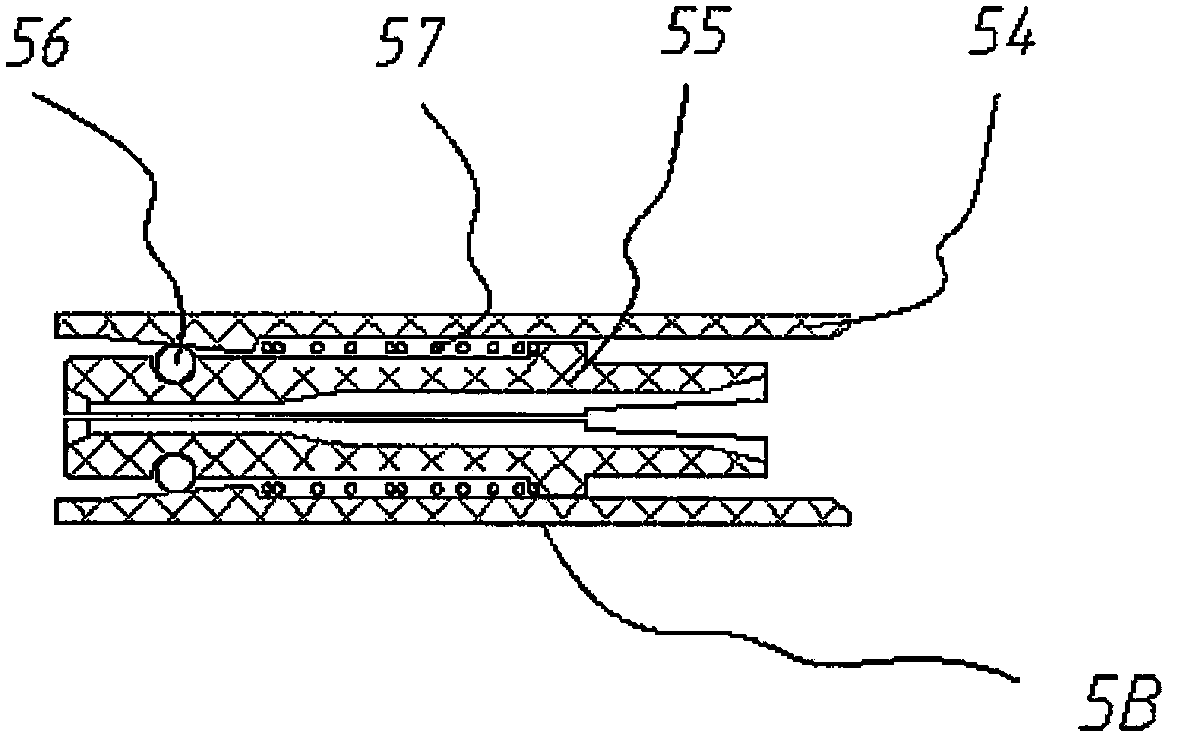

[0079] combine Figure 1 to Figure 5 , the body part 5B is packed into the tip cover part 5A, and as Figure 5 As shown, the inner ring groove 511 at the rear end of the tip sleeve 51 is closely matched with the outer ring groove 581 at the front end of the joint 58 , and the outer ring groove 582 at the rear end of the joint 58 is matched with the inner hole 591 of the core tube 59 . The lead core 5D passes through the inner hole 583 of the connector 58 from the inner hole 591 of the core storage tube 59, enters the groove 551 in the middle of the clip 55, and then enters the inner hole 521 of the movable damper 52, thereby forming a com...

Embodiment approach 2

[0083] Such as Figure 10 As shown, the fully automatic pencil in this embodiment is a push type, which consists of a pen holder 6, a pen holder 7 arranged on the pen holder 6, a pen neck 8, a push mechanism and a pen holder installed in the pen holder 6 and the pen neck 8. The fully automatic pencil movement 5 is composed of, wherein, the pressing mechanism includes a pressing head 9, a runner 10 and a guide rail 61 arranged in the pen holder 6 to cooperate with the pressing head 9, and a pressing spring 11 arranged in the front end of the pen neck 8 .

[0084] exist Figure 10 to Figure 12 In the shown embodiment, the fully automatic pencil movement 5 can adopt the same structure as the first embodiment, while the rear end of the storage core part 5C cooperates with the runner 10 and the front end of the tip sleeve part 5A cooperates with the push spring. 11 fits.

[0085] Specific as Figure 11 As shown, the rear end 592 of the storage core tube 59 of the automatic penc...

Embodiment approach 3

[0087] Such as Figure 13 As shown, the fully automatic pencil in the present embodiment is another form of the push-type fully automatic pencil, which consists of a penholder 13, a pen clip 14 located on the penholder 13, a pen neck 15, a pressing mechanism and a The full-automatic pencil movement 12 in pen holder 13 and pen neck 15 forms. Wherein, the pressing mechanism in this embodiment includes a pressing head 16 and a pressing core 17 respectively matched with the rear end of the storage core part 5E of the fully automatic pencil movement 12, as well as being arranged in the front end of the pen neck 15 with the tip sleeve. The push spring 11 matched with the front end of the component 5A, the push core 17 includes an elastic boss 172 matched with the grip point 142 provided on the pen holder 14, and the side of the penholder 13 is provided with accommodating grip points 142 and the window 131 of the elastic boss 172.

[0088] combine Figure 14 with Figure 15, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com