Patents

Literature

34results about How to "Realize automatic compensation function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

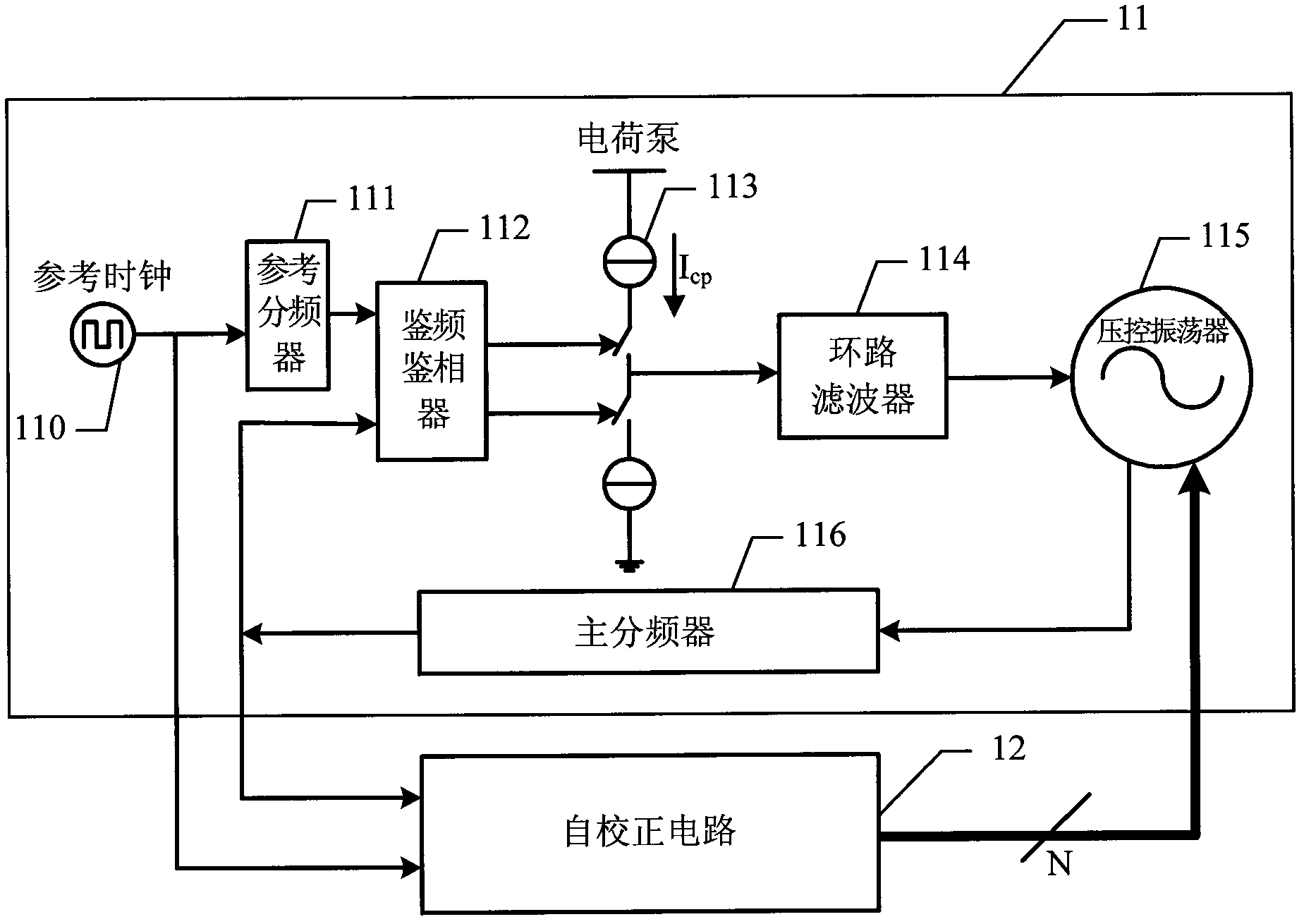

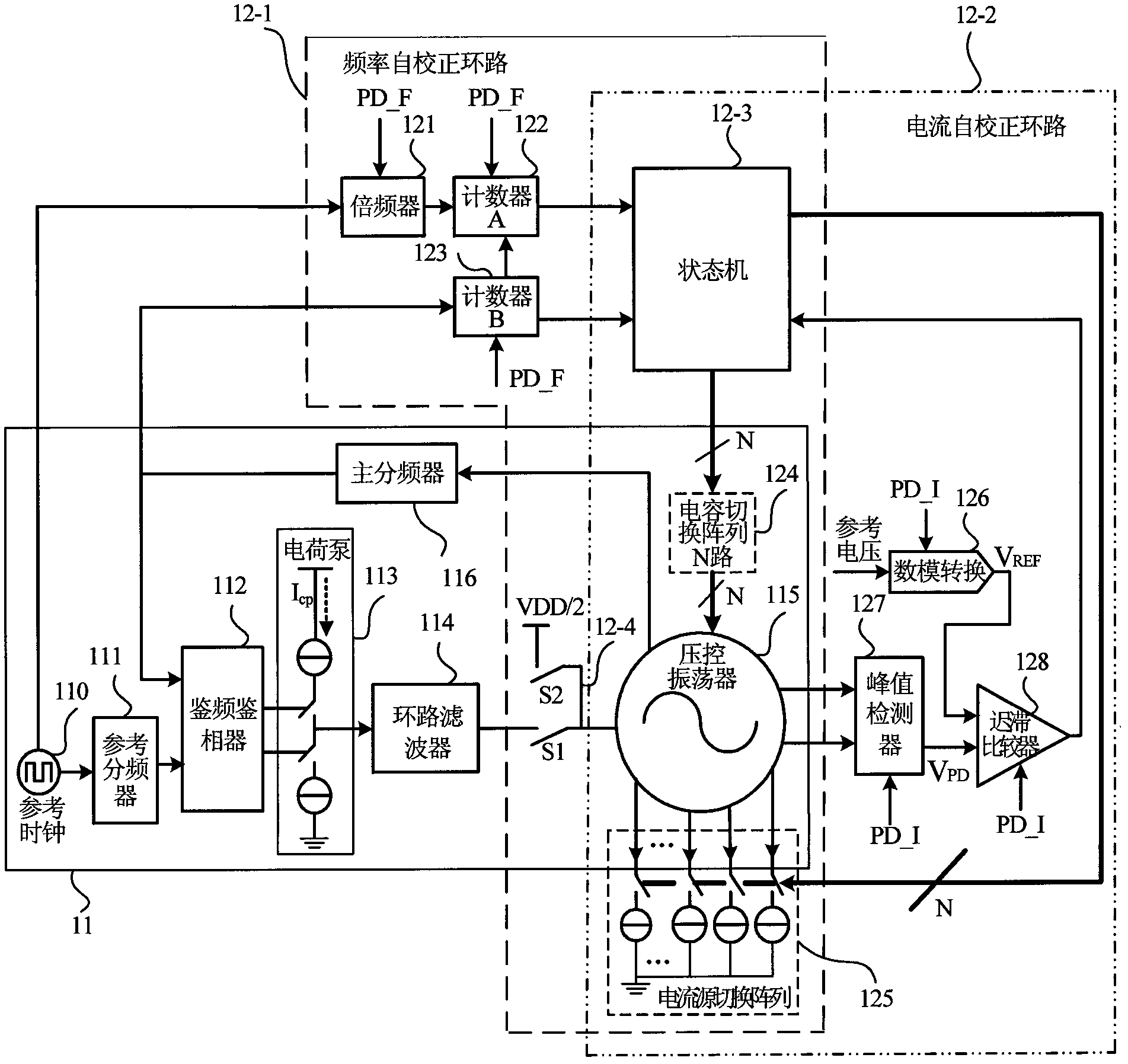

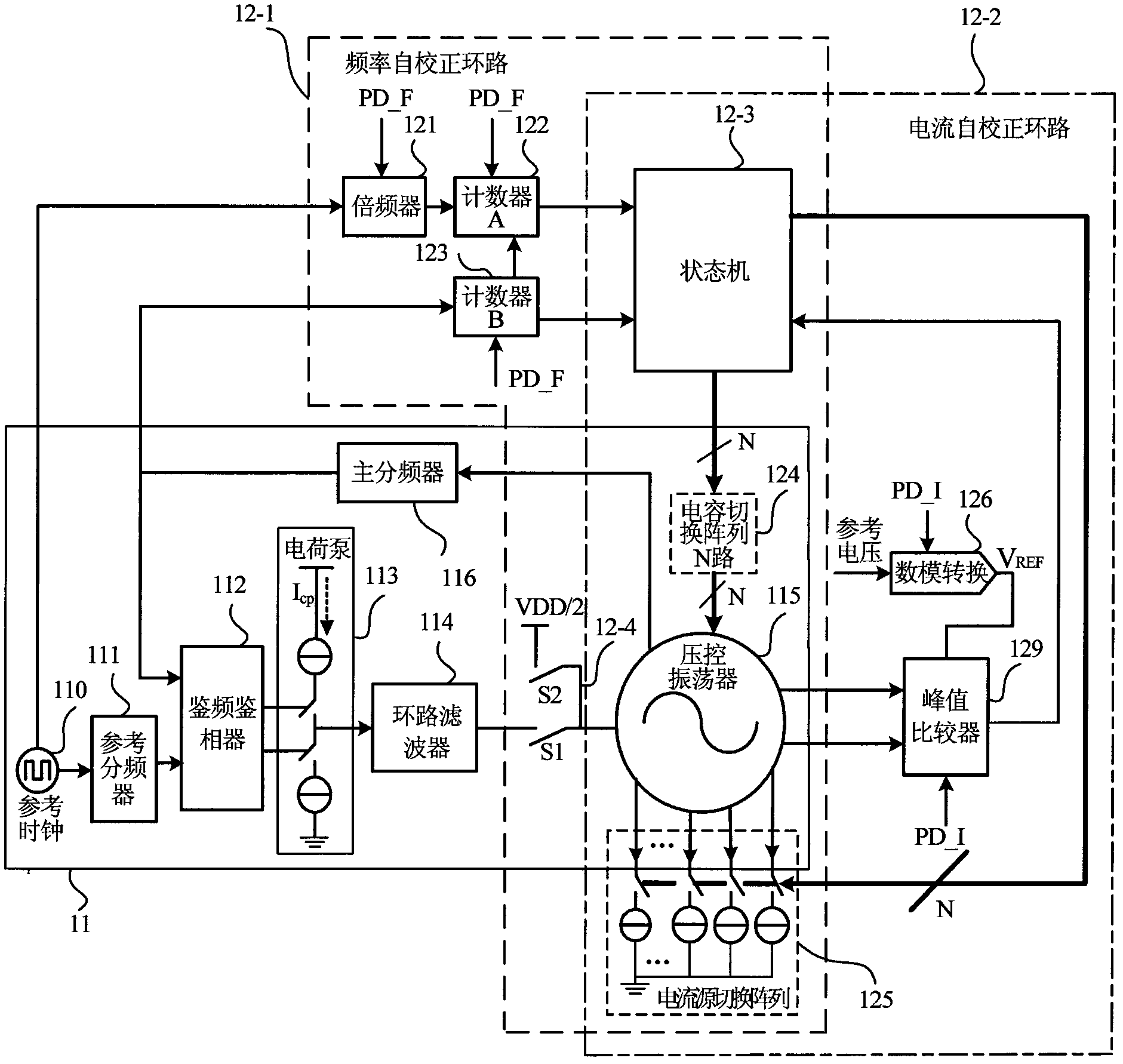

Self-correcting frequency synthesizer capable of optimizing properties of voltage-controlled oscillator and optimizing method of self-correcting frequency synthesizer

ActiveCN102868397ALarge frequency adjustment rangeFulfil requirementsPulse automatic controlProcess deviationsMulti band

The invention discloses an optimizing method of a self-correcting frequency synthesizer capable of optimizing properties of a voltage-controlled oscillator. The method comprises the following steps that: when a chip is electrified or a channel is changed each time, a frequency self-correcting loop in a synthesizer self-correcting circuit is started firstly, and a frequency sub-wave band code necessary for the voltage-controlled oscillator is searched; secondly a current self-correcting loop in the synthesizer self-correcting circuit is started, and a current sub-wave band code that an output amplitude of the voltage-controlled oscillator achieves an appointed amplitude is searched, so that the voltage-controlled oscillator works in a minimum power consumption, a good phase noise property is obtained, and at the same time the properties of the voltage-controlled oscillator are not changed when process deviation and temperature change occur; after the accomplishment of frequency correction and current correction is judged by a state machine, a synthesizer enters into the frequency self-locking process of a phase-locked loop; and the optimization and correction process is ended. The invention further discloses the self-correcting frequency synthesizer capable of optimizing the properties of the voltage-controlled oscillator. A wider frequency adjustment range can be obtained, and good local oscillator spectrum purity is obtained through small power consumption; and the optimizing method is suitable for the self-correcting frequency synthesizer of a transceiver with low power consumption, multiple modes and multi-band frequency.

Owner:杭州中科微电子有限公司

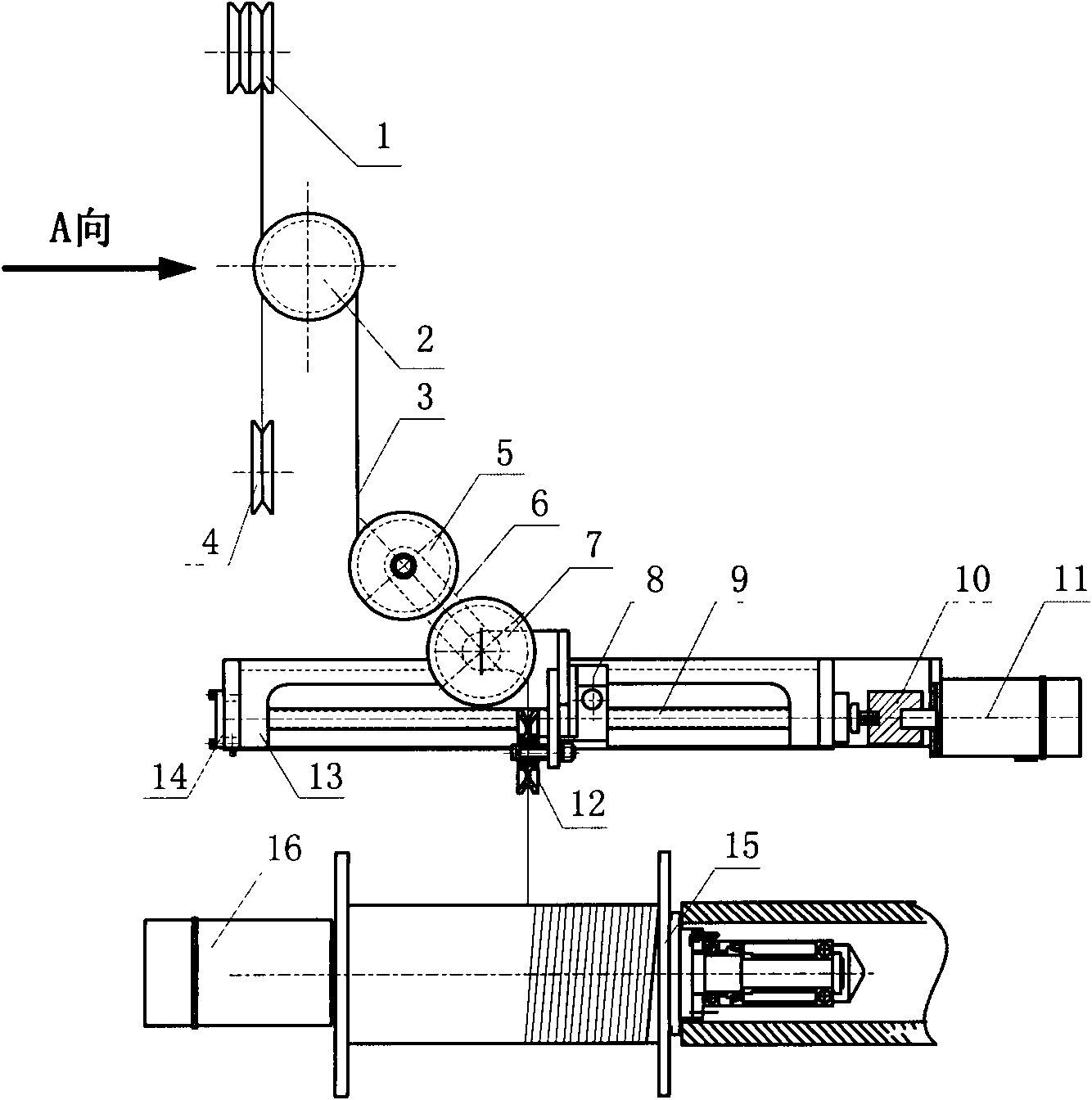

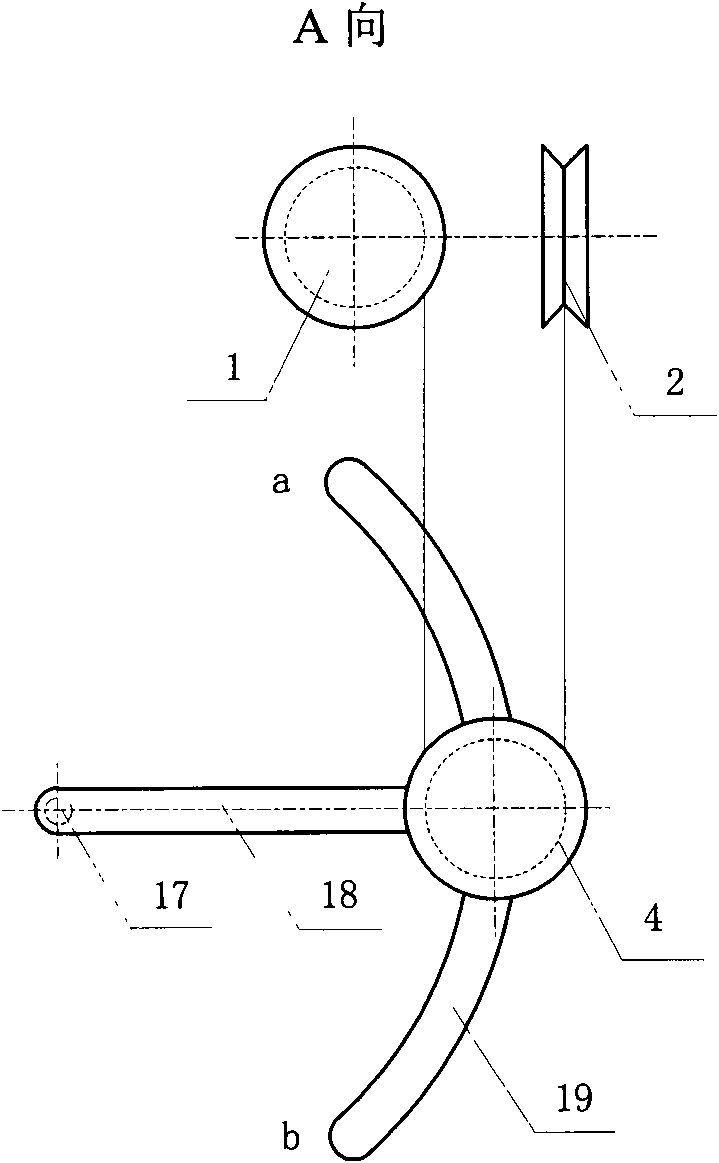

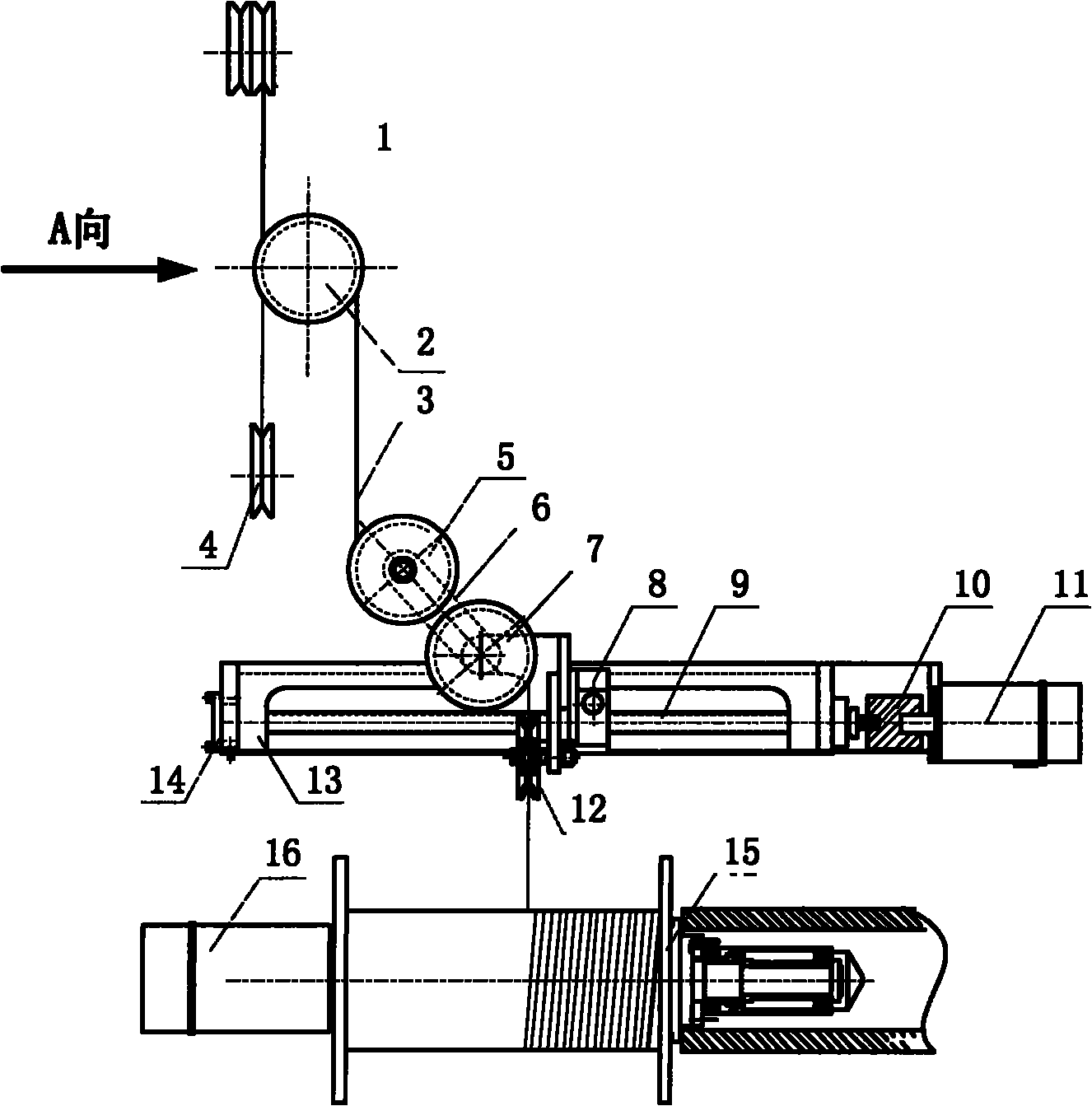

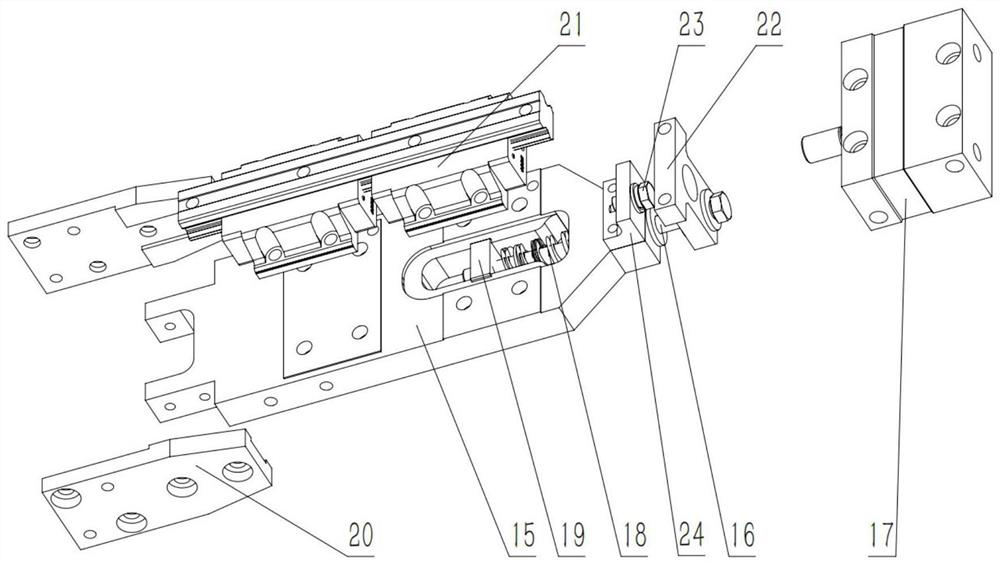

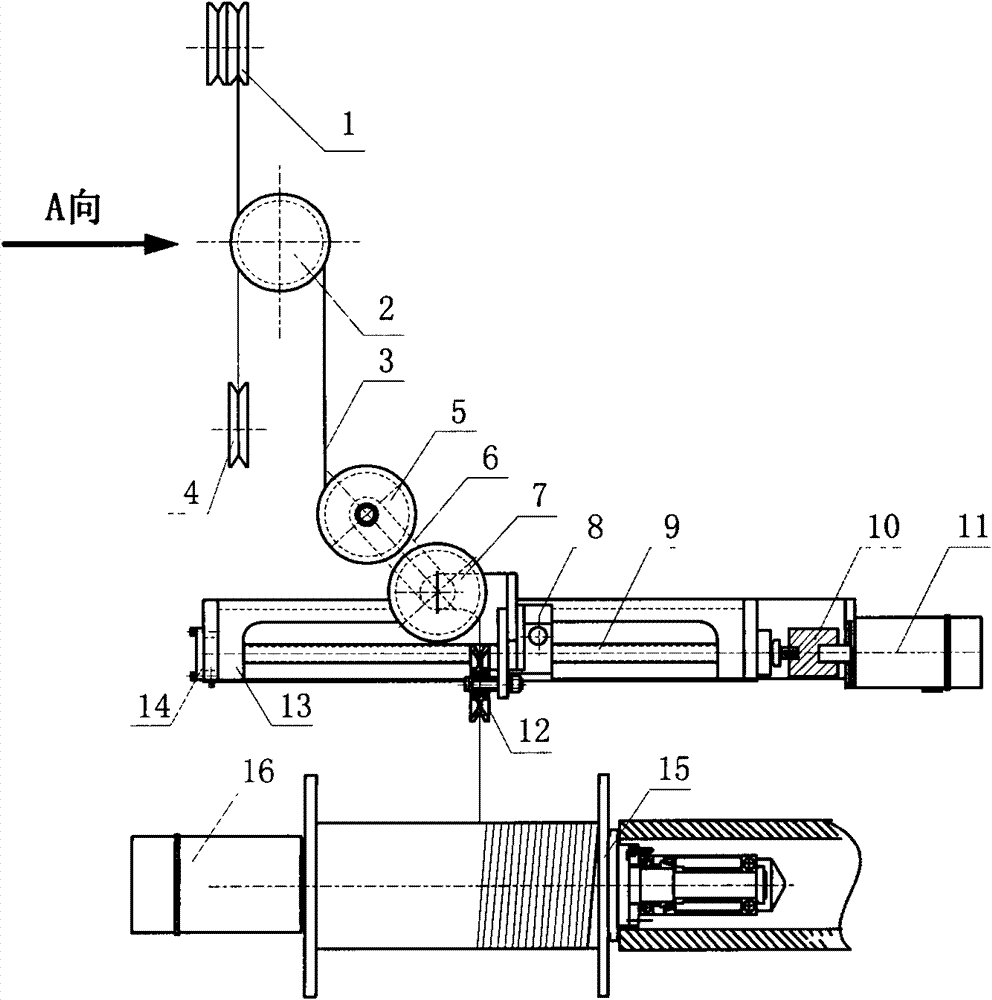

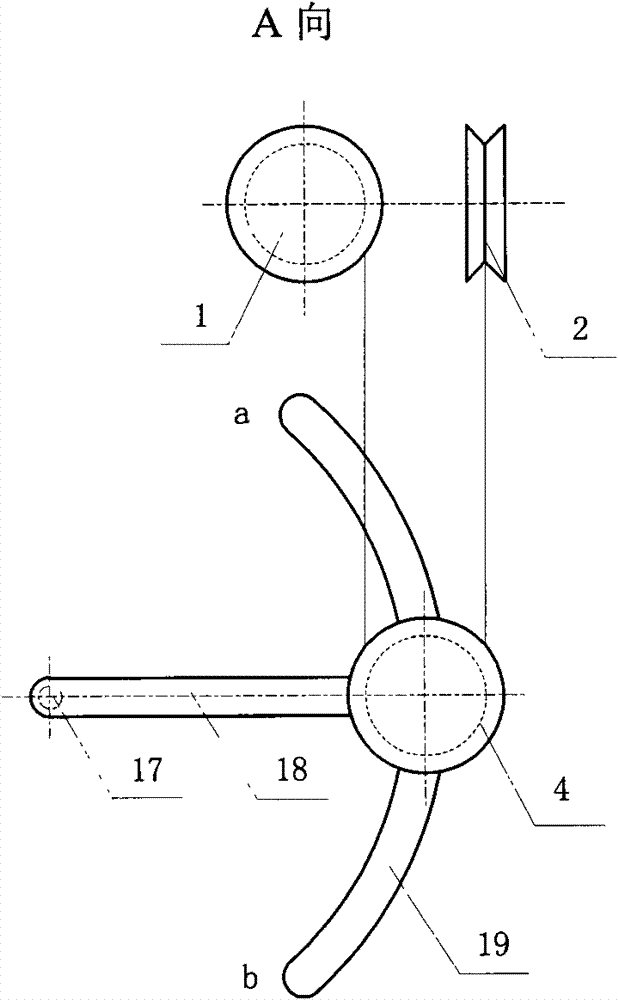

Self-compensating servo wiring device for water tank type wire drawing machine

ActiveCN102172669AWith disconnection alarm functionAvoid the phenomenon of "rising wheel"Metal working apparatusBall screwEngineering

The invention discloses a self-compensating servo wiring device for a water tank type wire drawing machine, which comprises a tension testing unit, a wire distributing device and a wire collecting device, wherein the tension testing unit consists a first wire roller, a second wire roller, a tensioning wire roller, an angular displacement sensor, a tension rod and a guide groove; the wire distributing device consists a third wire roller, a synchronous belt, a fourth wire guide roller, a screw nut, a ball screw, a coupler, a wiring servo motor, a fifth wire roller, a wiring base and an end cover; and the wire collecting device consists of a spool and a wire collecting servo motor. The device adopts the tensioning wire roller for testing the tension of a metal wire, has a simple structure and has a metal wire breakage alarming function for giving an alarm in time incase of breakage of the metal wire.

Owner:JIANGSU HENGLI MACHINE TOOL

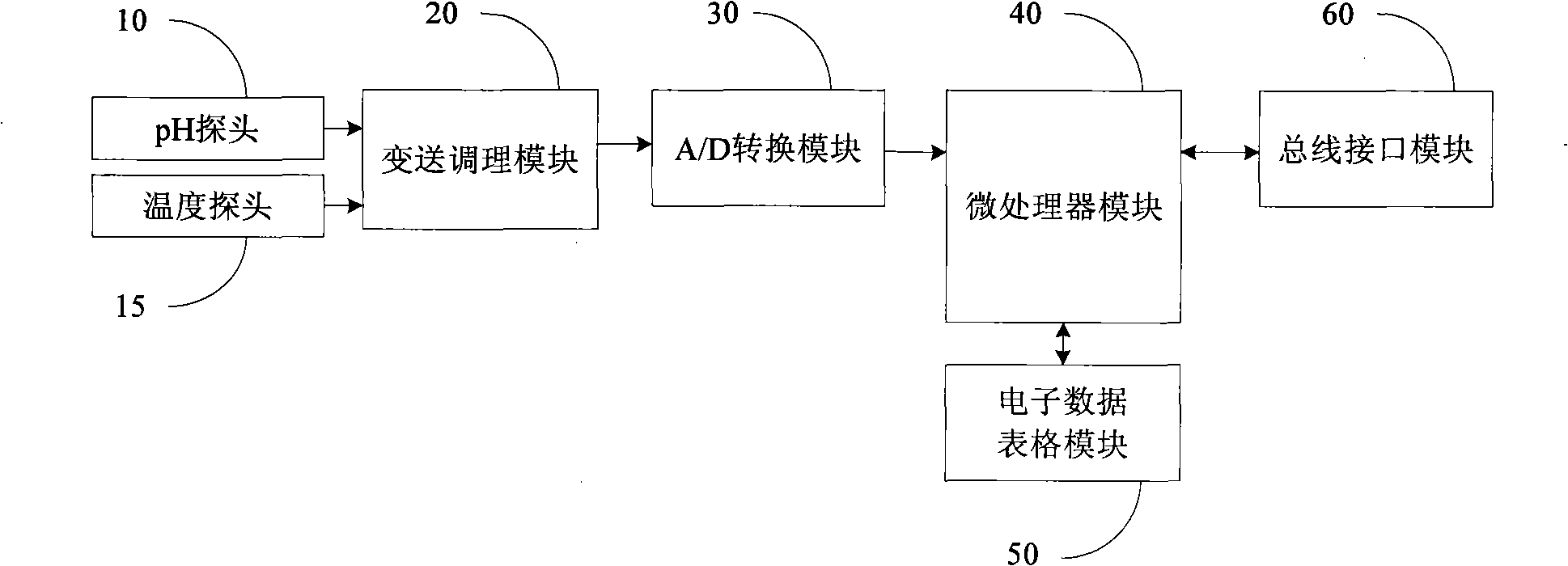

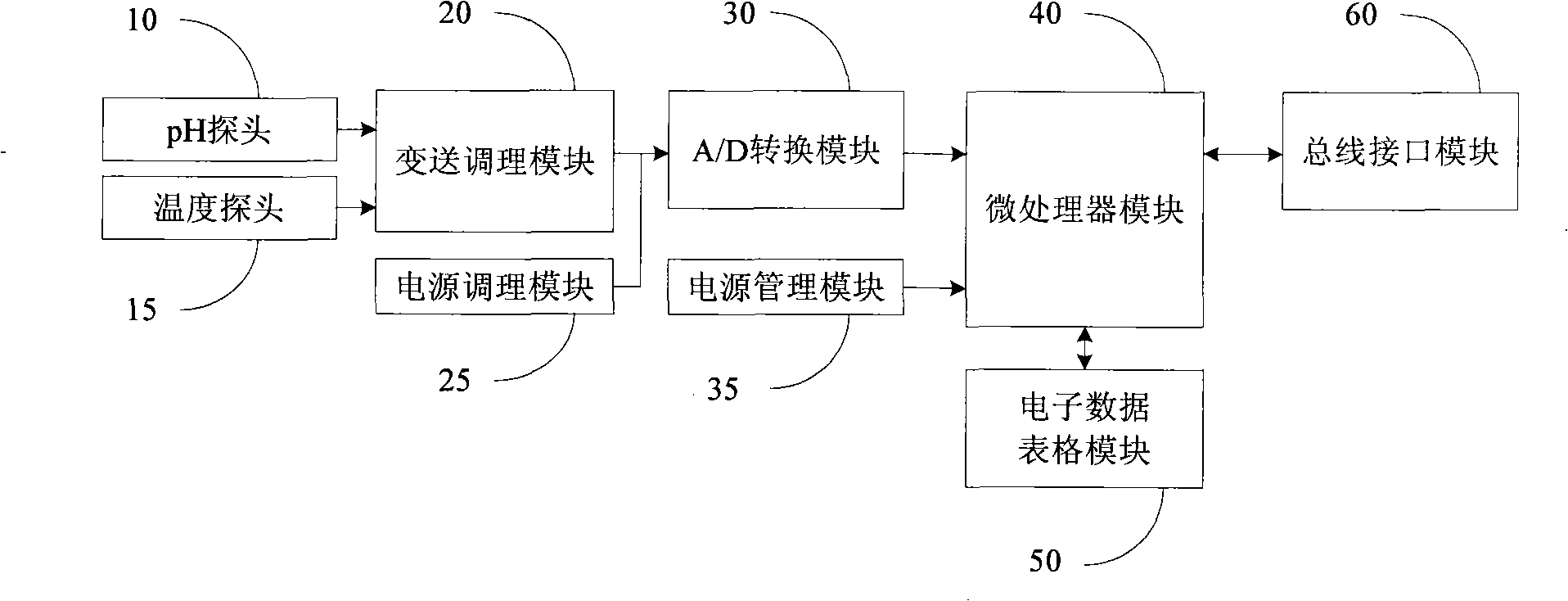

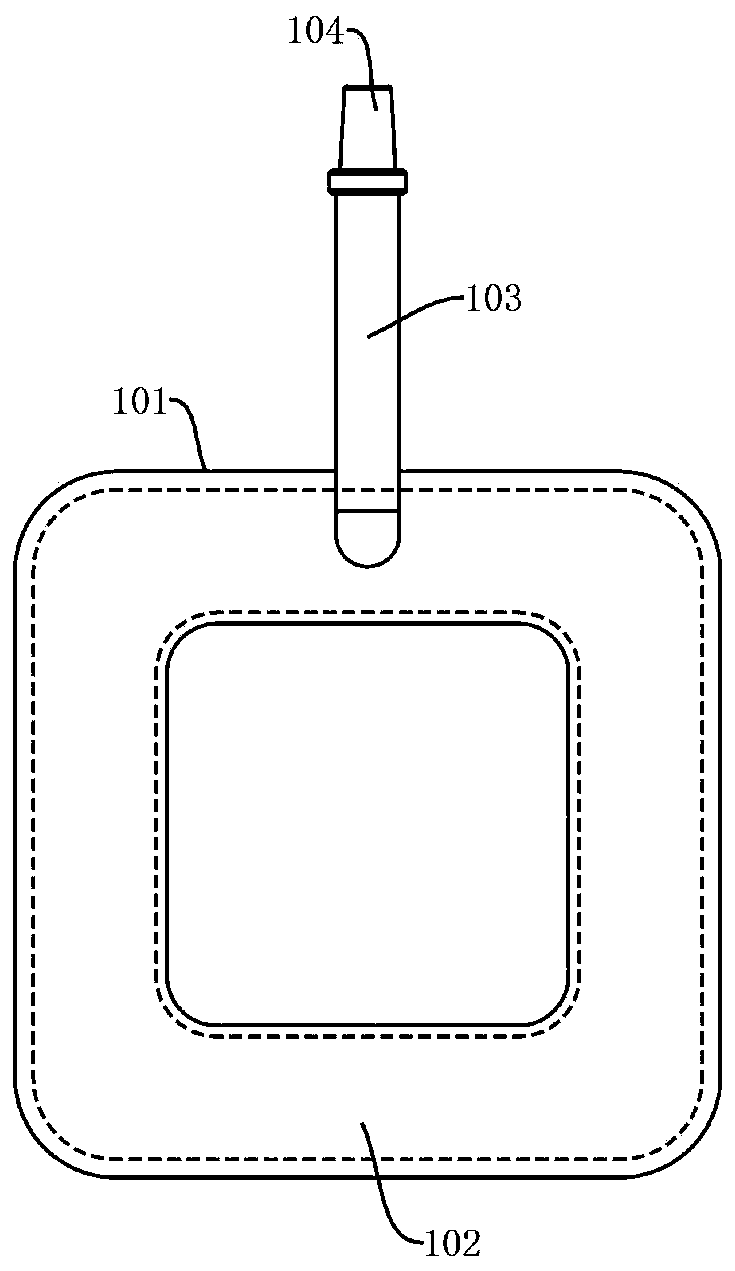

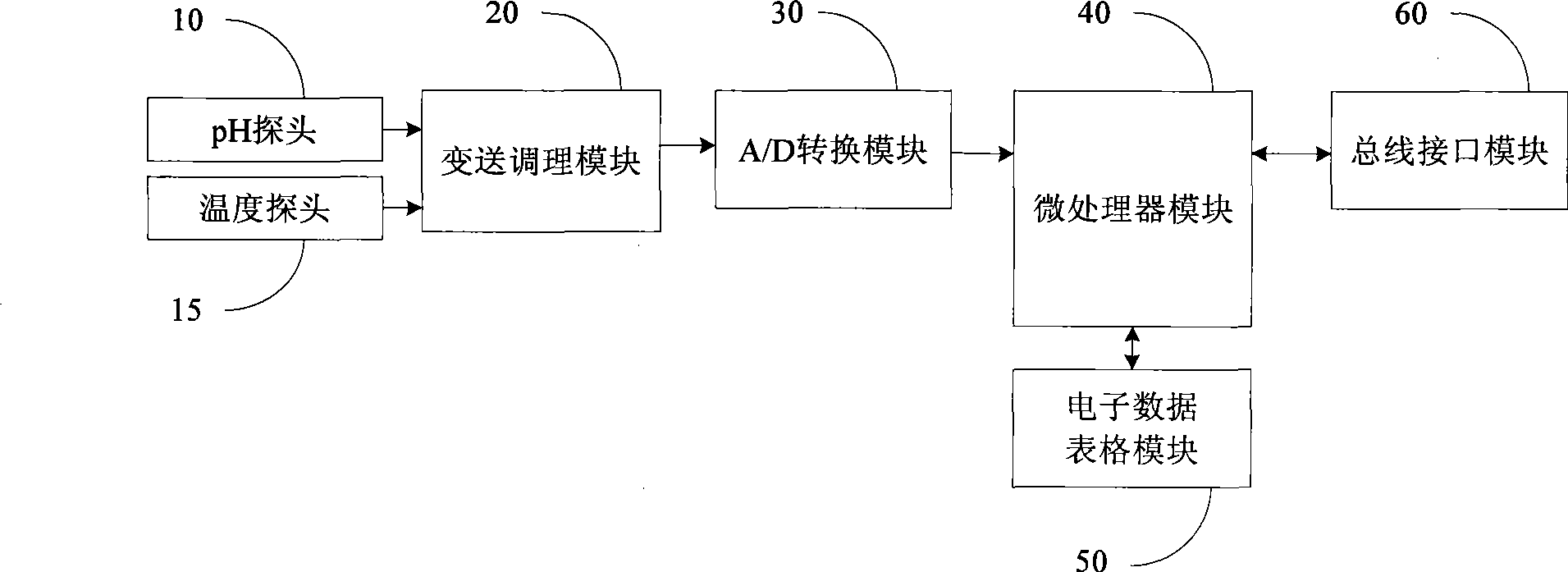

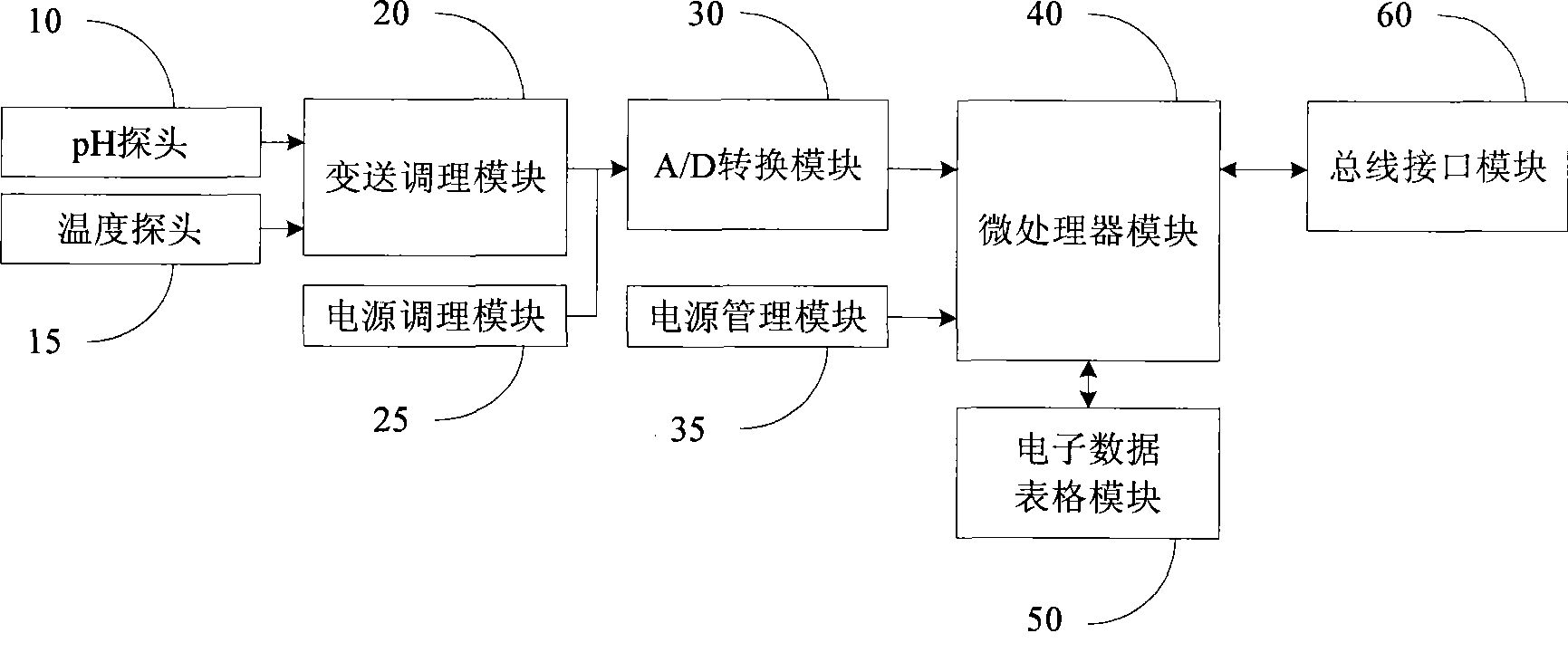

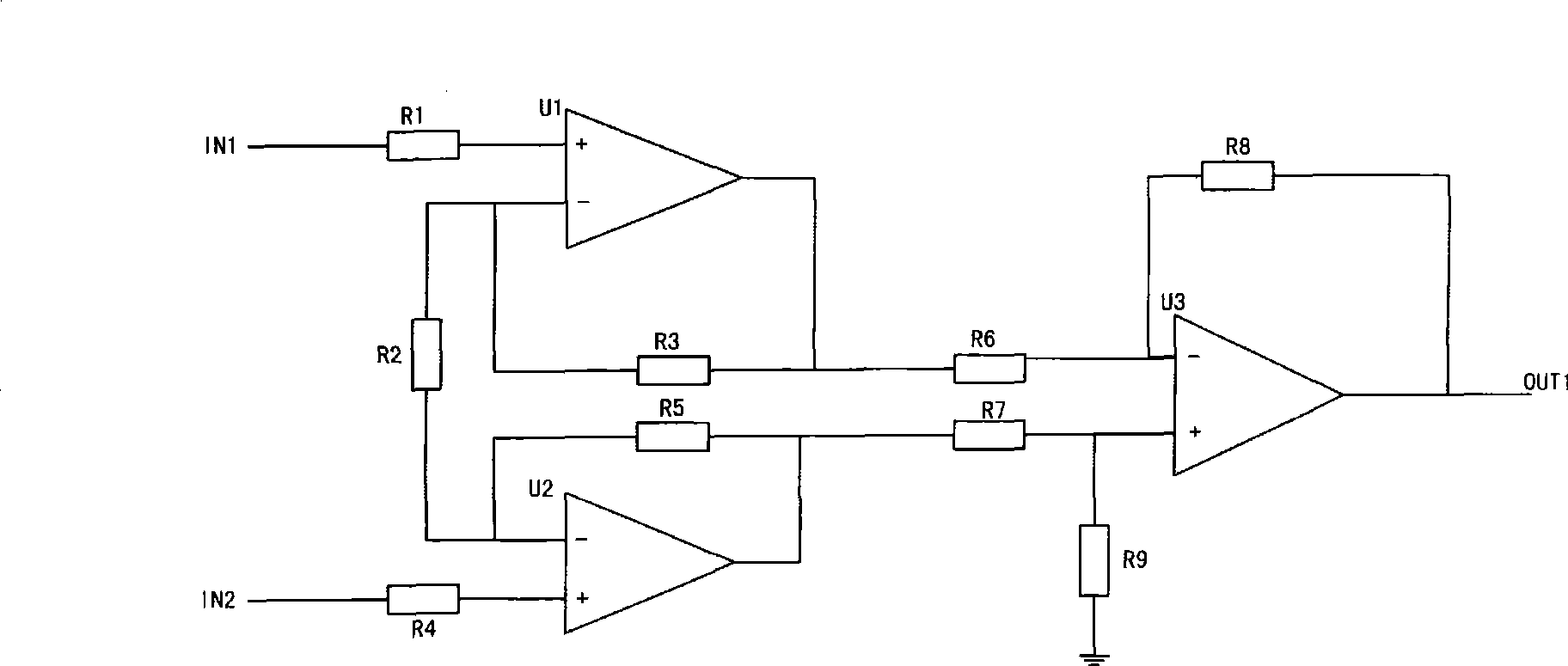

Intelligent transmission apparatus for pH value of water

InactiveCN101343104ARealize plug and playRealize intelligenceWater/sewage treatment by neutralisationWater qualityTransmitter

The invention develops a water quality pH value intelligent transfer device for intensive water quality monitoring applications, aiming at the status quo of urgent need of automatic water quality monitoring technique in intensive aquaculture in China. The intelligent transfer device integrates the water quality parameter signal conditioning technique and the transfer technique, and is directly input with signals of water temperature and pH value sensor probes, and is embedded with a high performance microprocessor, the device utilizes the self-calibration technique to realize the pH value automatic temperature compensation function on the basis of signal acquisition of probes, and also adopts an intelligent network interface model described in the IEEE1451 standard to realize the self-diagnosis and plug-and-play functions of an intelligent transmitter. The water quality pH transfer device is advanced to develop towards intelligence, networking and miniaturization, thereby raising the water quality monitoring level of intensive aquaculture.

Owner:CHINA AGRI UNIV

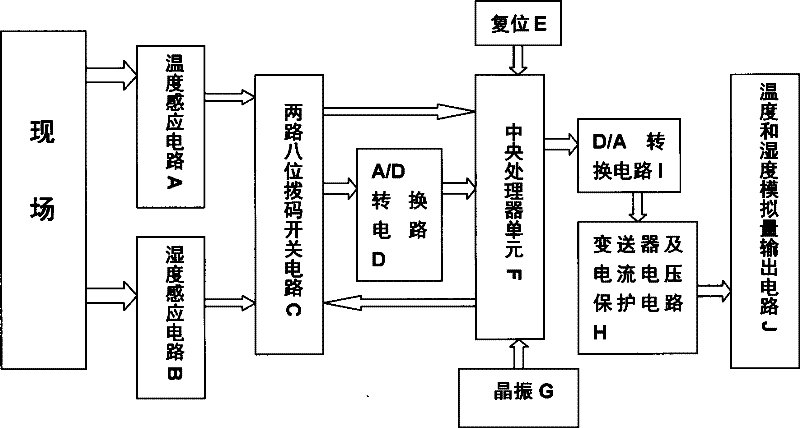

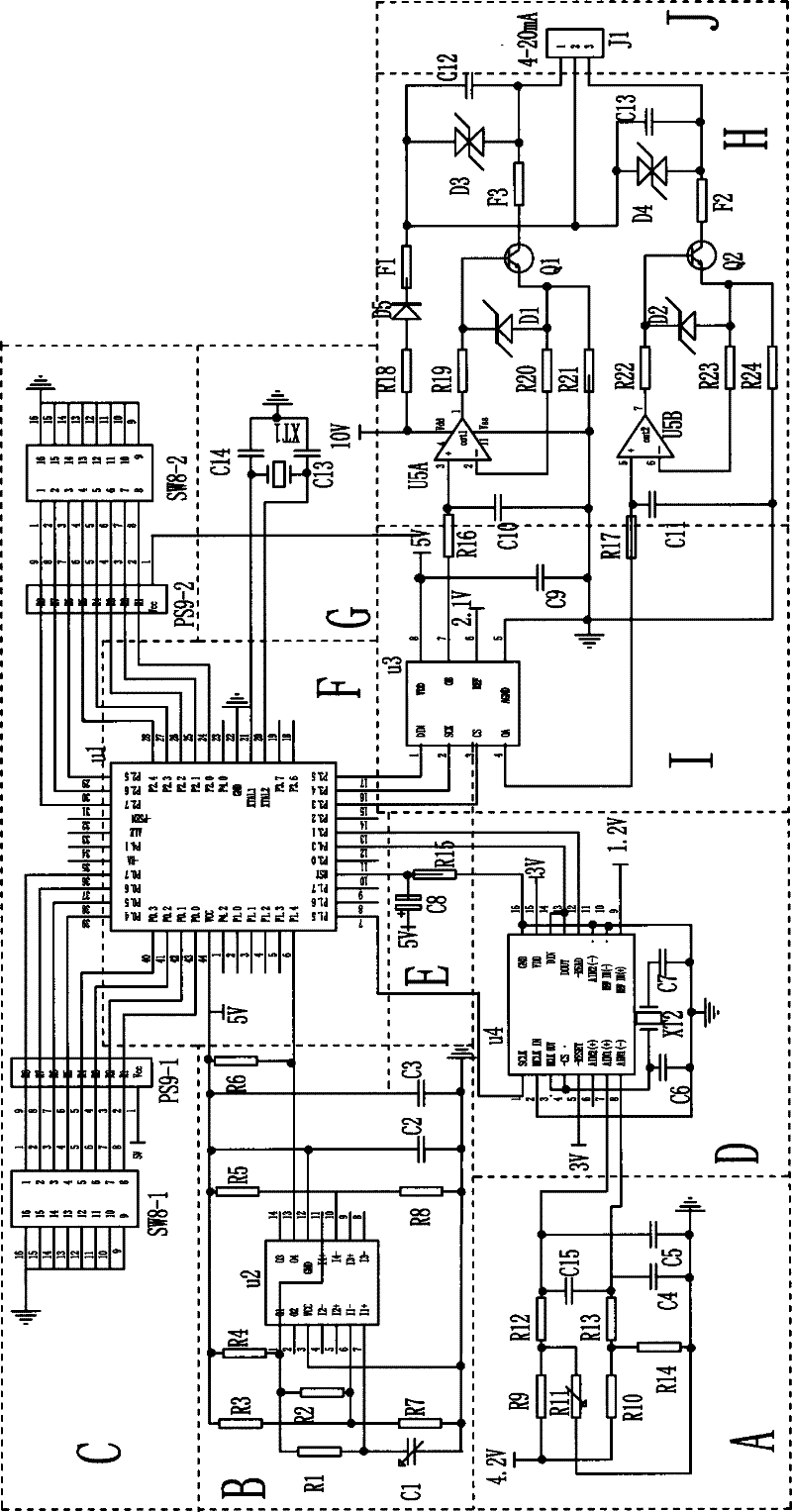

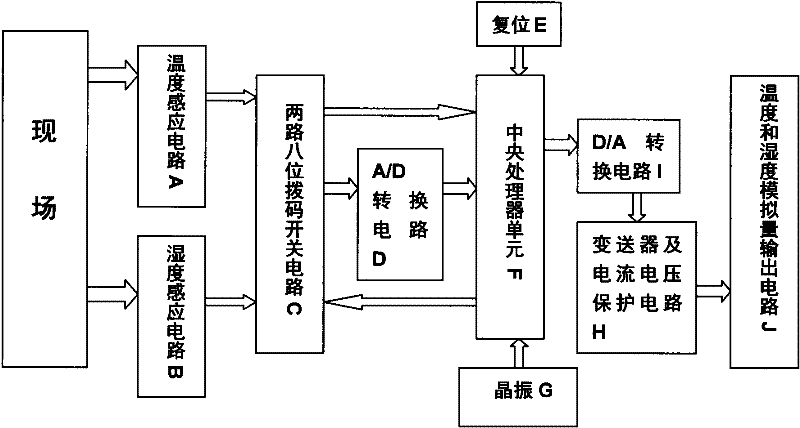

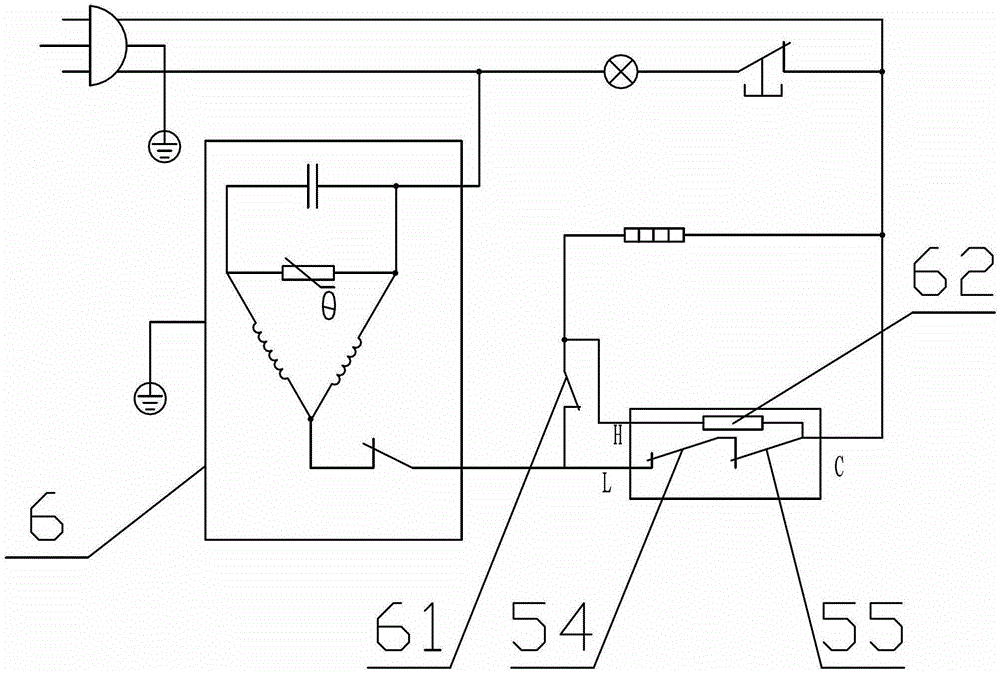

Digital temperature and humidity detection device

InactiveCN102589614ARealize validity checkRealize automatic compensation functionMeasurement devicesEngineeringMoisture sensor

The invention relates to a digital temperature and humidity detection device. The digital temperature and humidity detection device structurally consists of a temperature induction circuit A, a humidity induction circuit B, a two-way eight-position dial-up switching circuit C, an analog / digital (A / D) conversion circuit D, a reset circuit E, a central processor unit F, a crystal oscillator circuit G, a digital / analog (D / A) conversion circuit I, a loosening device and voltage / current protective circuit H and a temperature and humidity analog quantity output circuit J, wherein the temperature induction circuit A, the humidity induction circuit B, the A / D conversion circuit D, the central processor unit F, the D / A conversion circuit I, the loosening device and voltage / current protective circuit H, and the temperature and humidity analog quantity output circuit J form a main circuit; the two-way eight-position dial-up switching circuit C provides temperature and humidity compensation data during calibration of a temperature and humidity sensor; and the reset circuit E, the crystal oscillator circuit G and the central processor unit F are connected to provide necessary support for the work.

Owner:高鹤

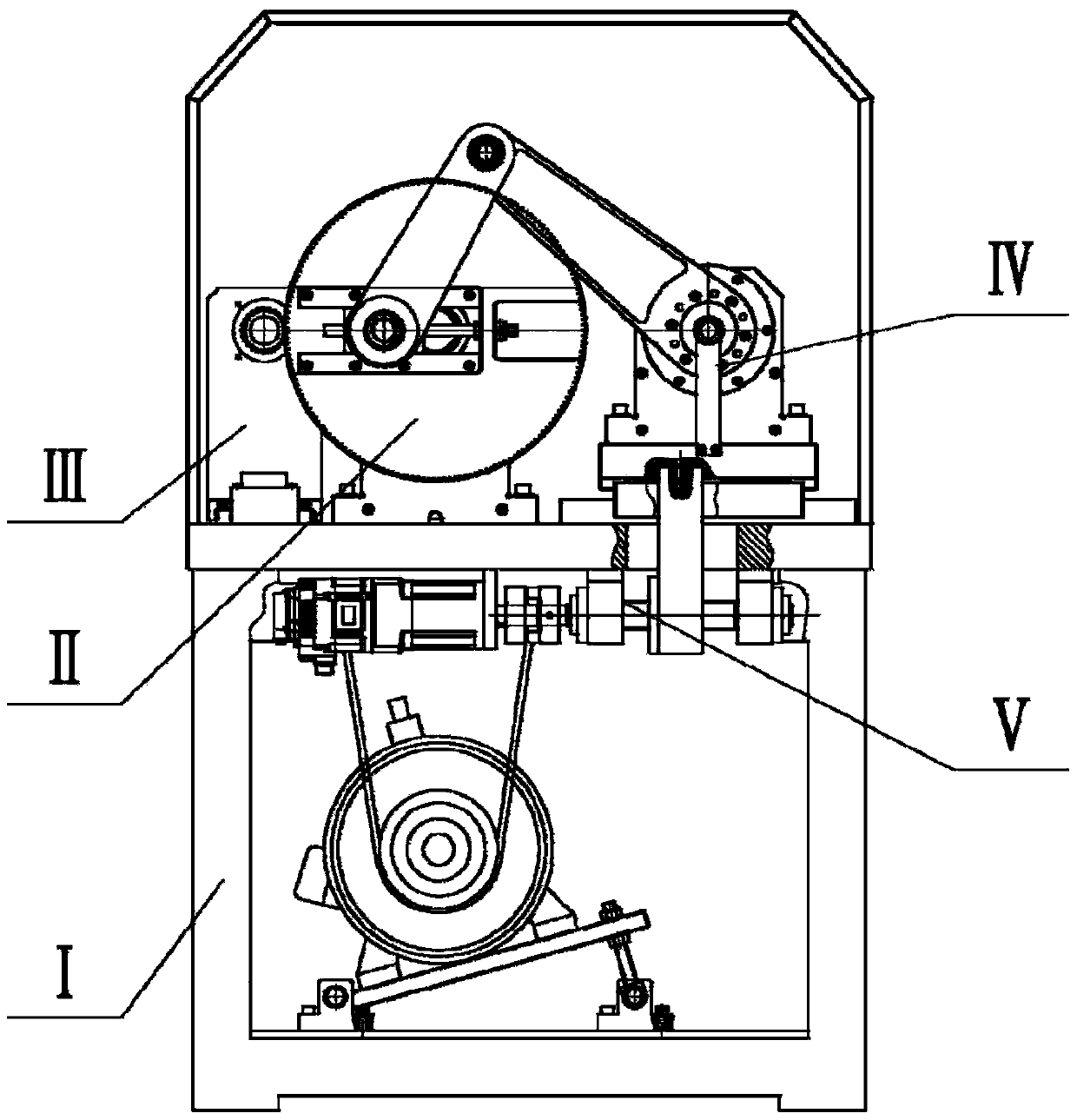

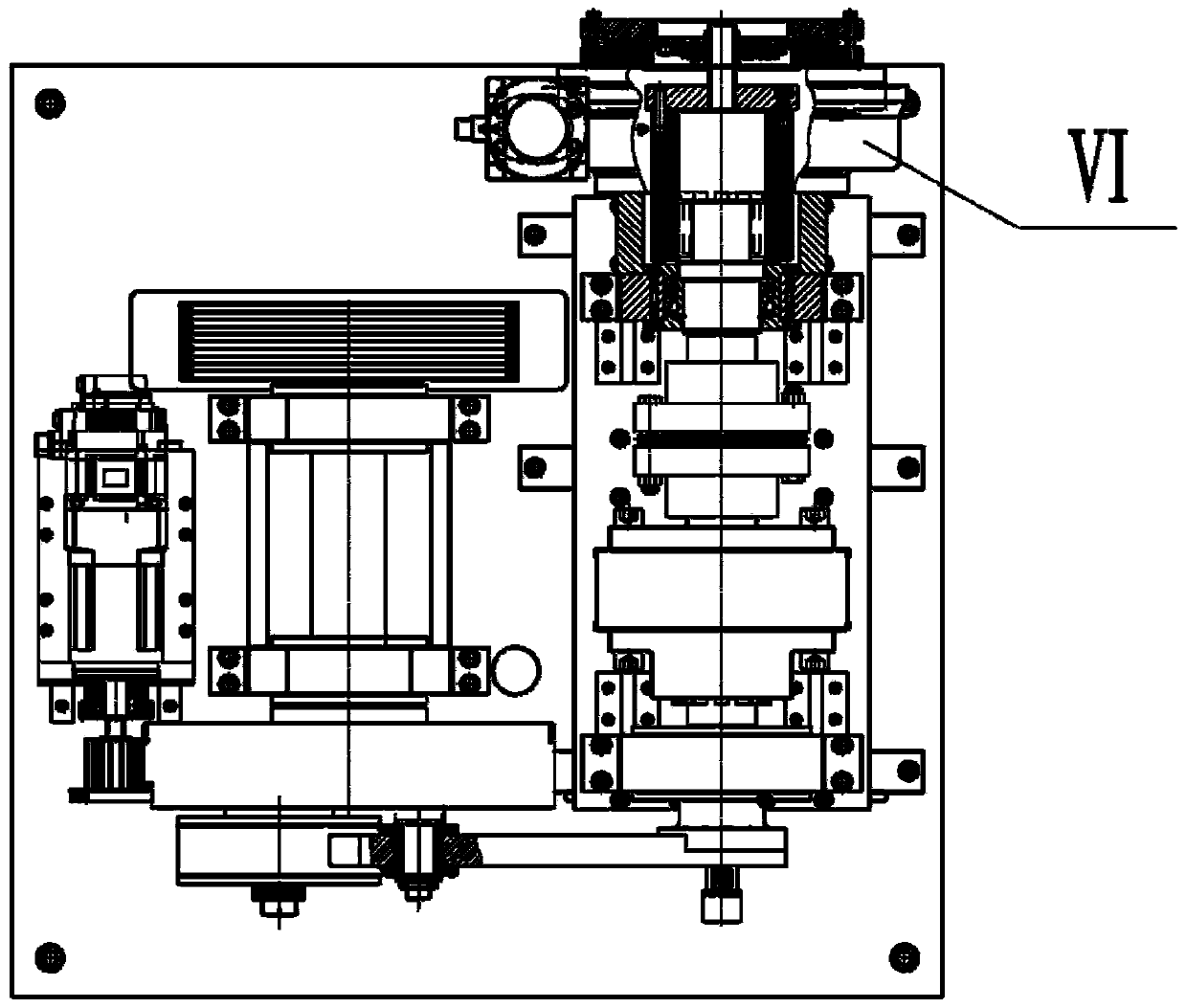

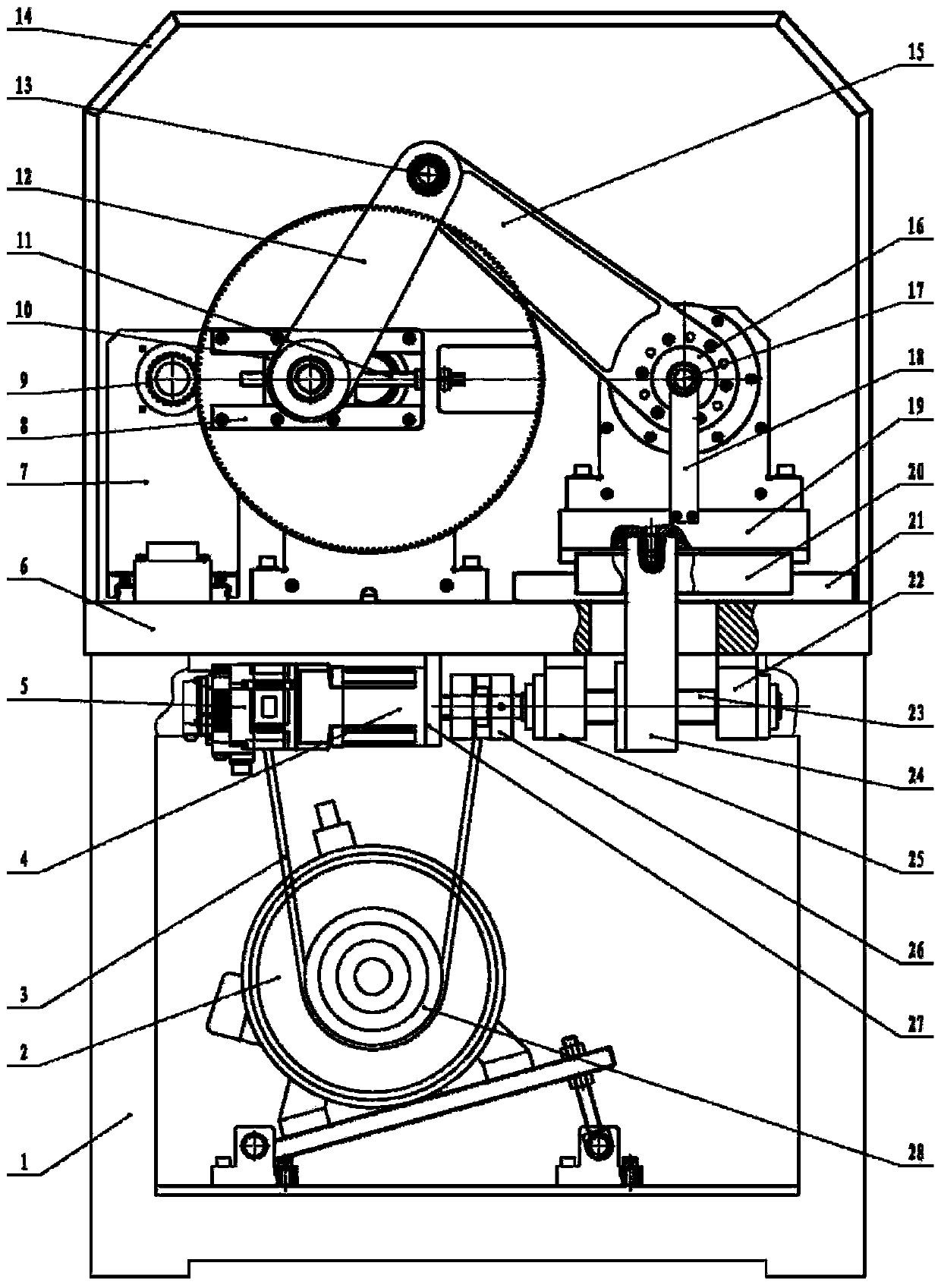

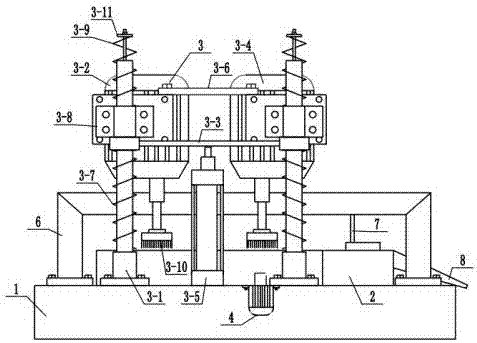

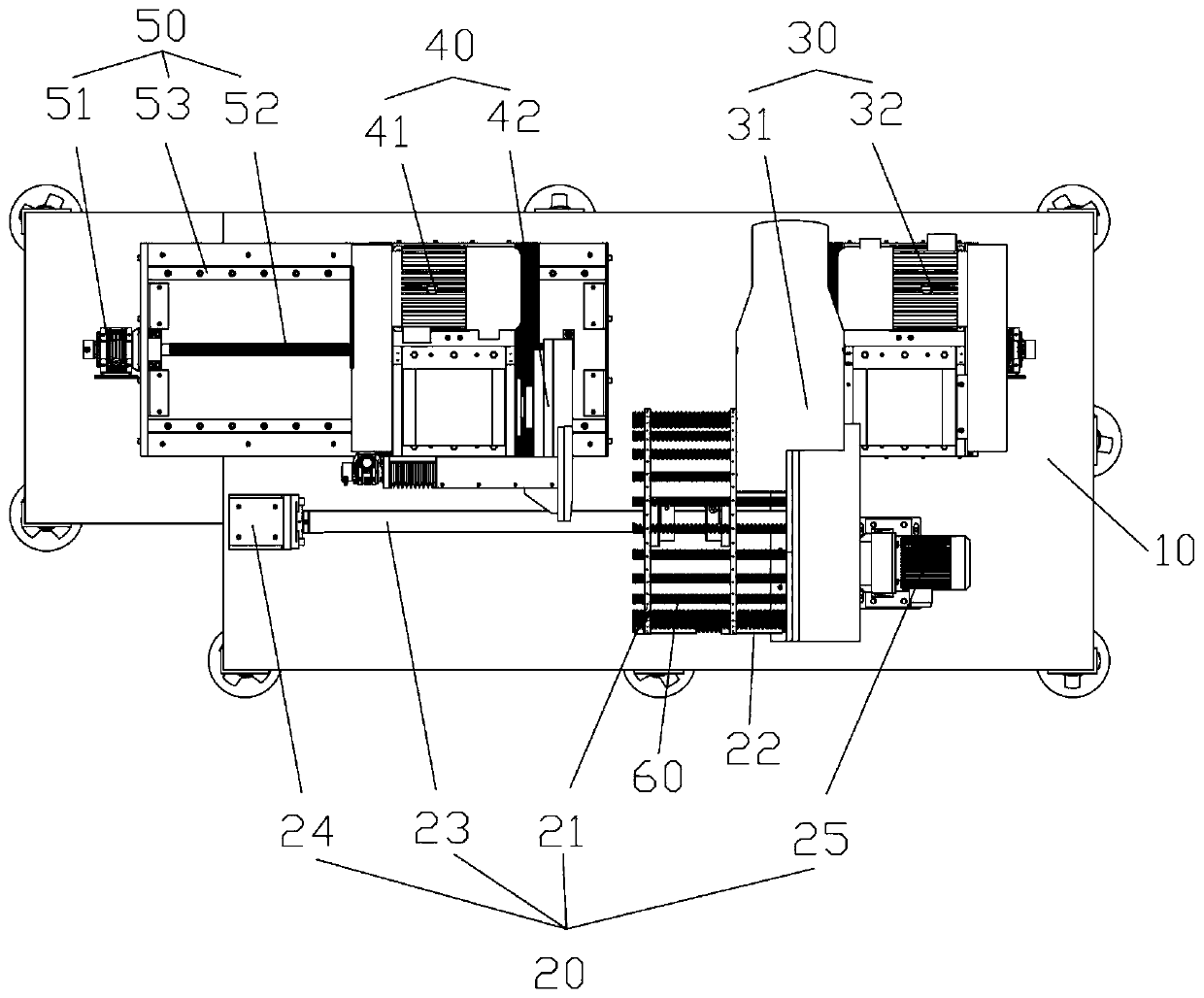

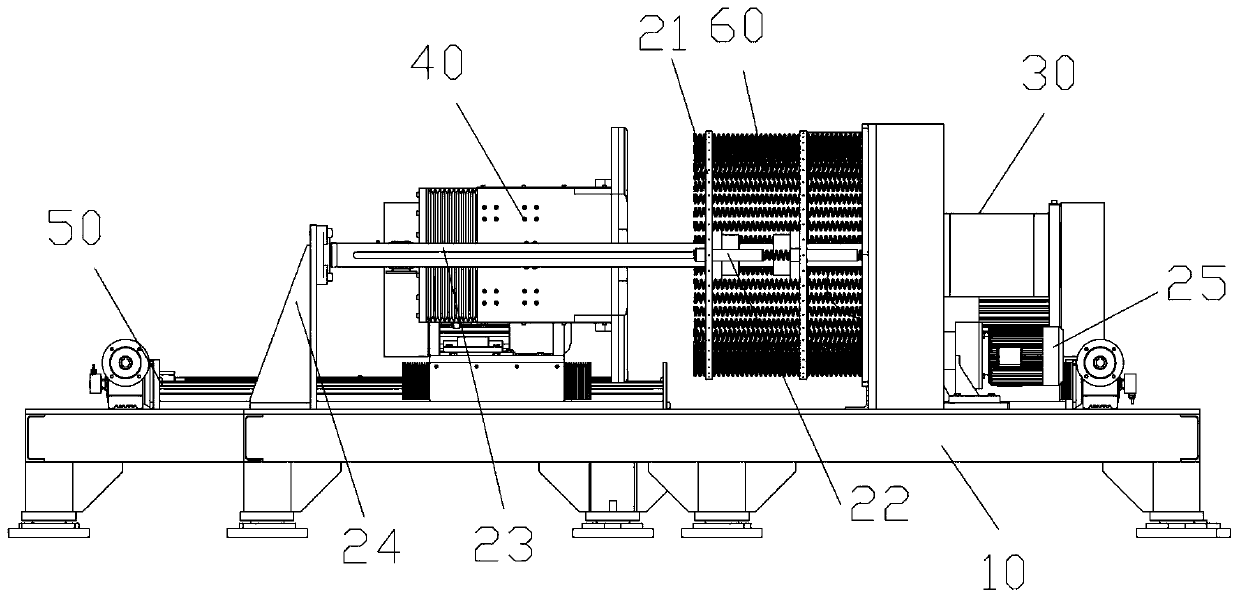

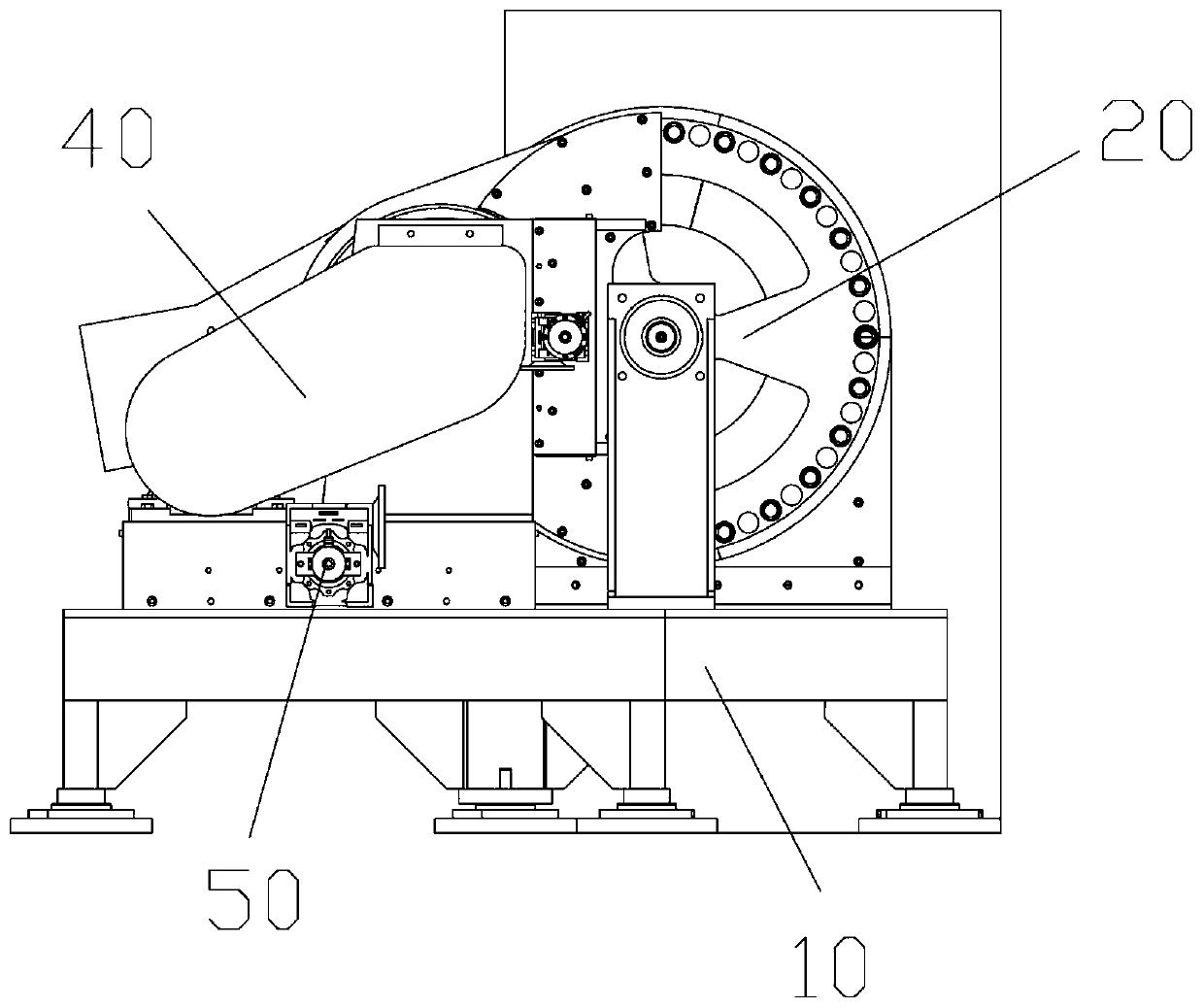

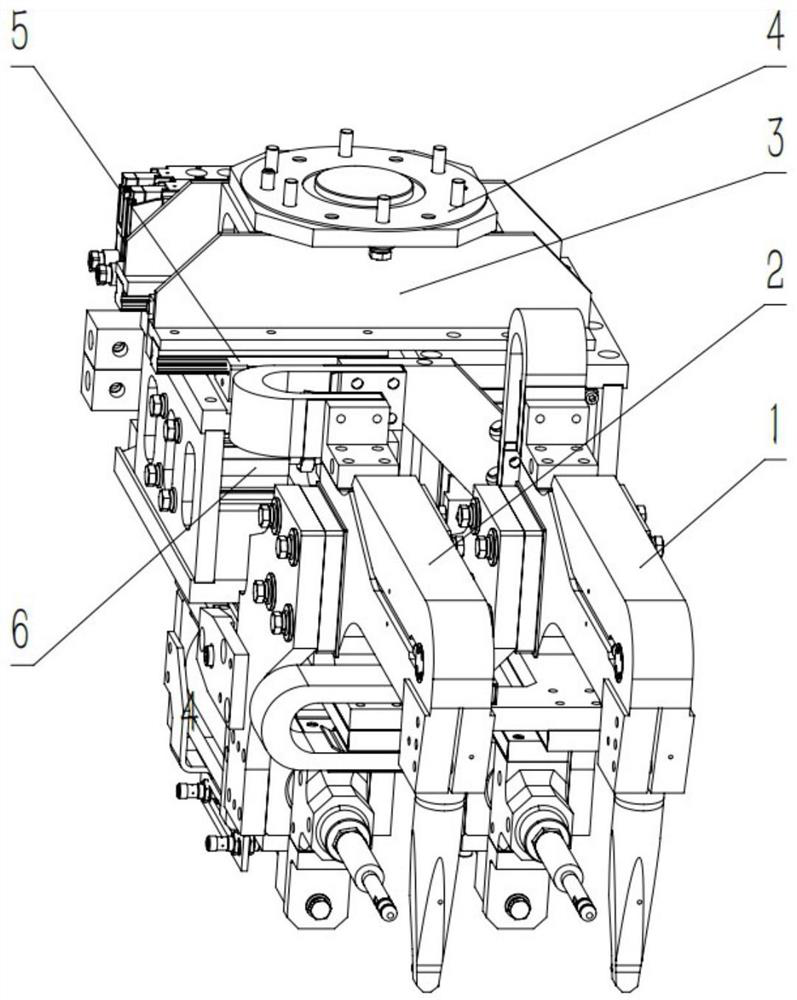

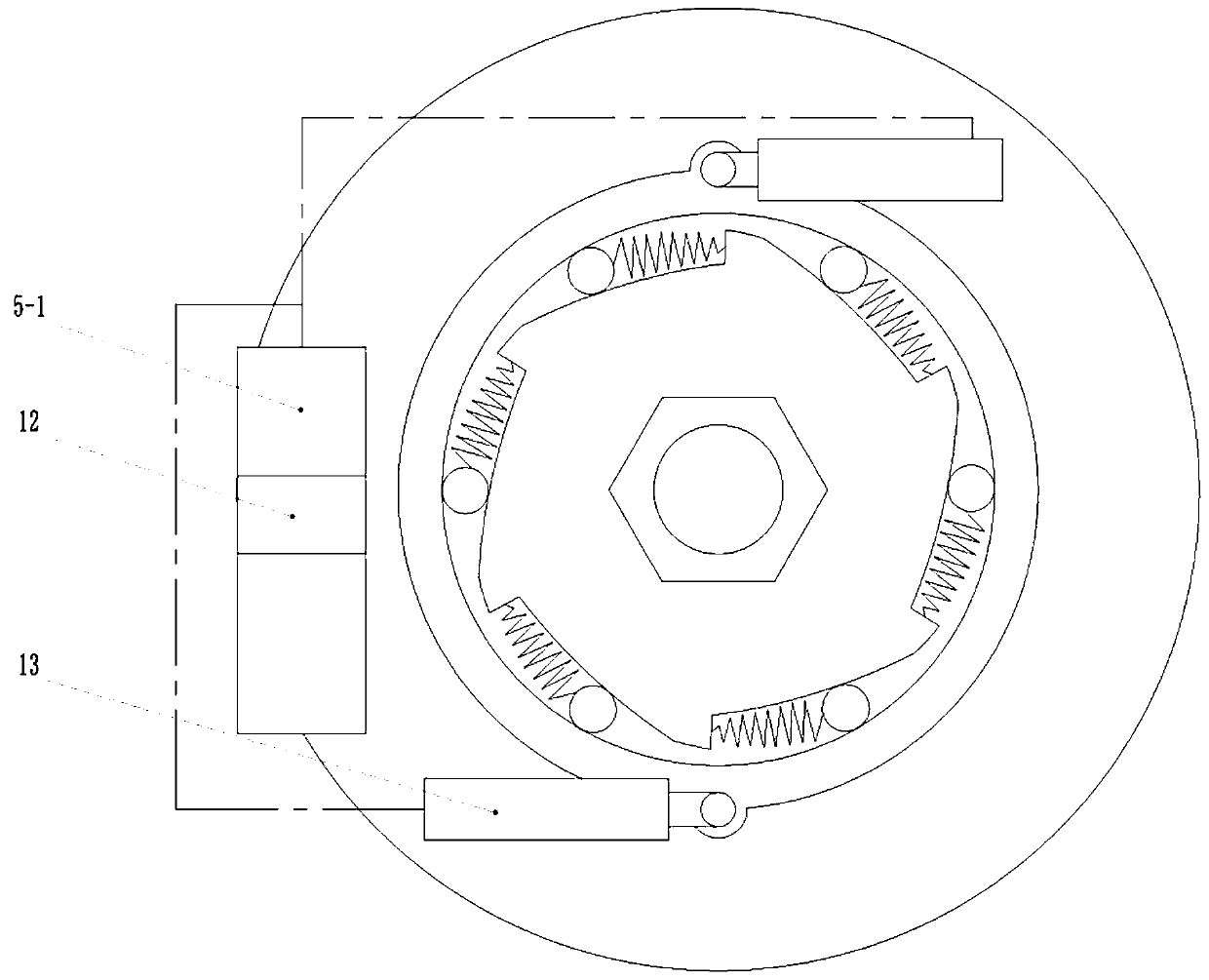

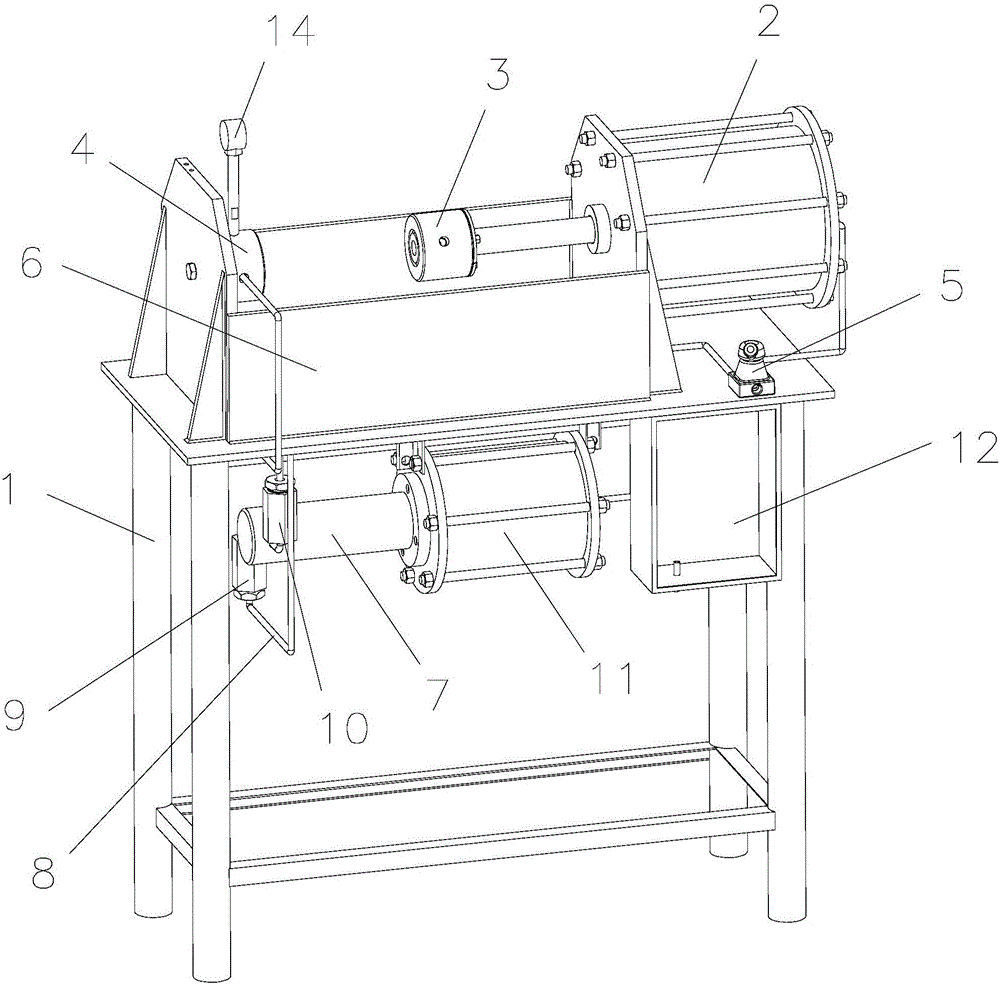

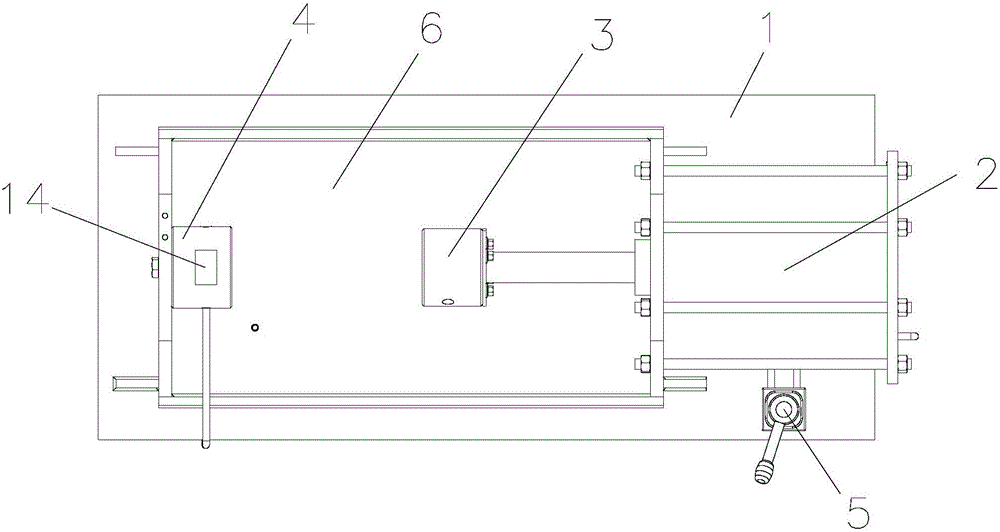

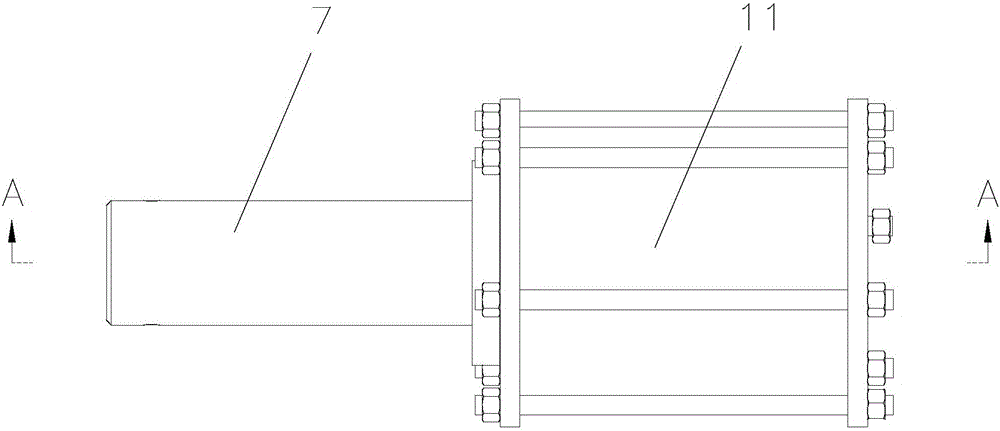

Torsion durability fixed torque testing machine for automobile dry friction type clutch driven plate assembly

PendingCN110031235ASimple structureEasy to useVehicle testingMachine gearing/transmission testingClutchObservational error

The invention discloses a torsion durability fixed torque testing machine for an automobile dry friction type clutch driven plate assembly, which mainly comprises a base, a driving mechanism, a manualdriving loading mechanism, a torsion mechanism, a compensation mechanism and an aligning mechanism, wherein the driving mechanism, the manual driving loading mechanism, the torsion mechanism and thecompensation mechanism are respectively fixed on the base, and the aligning mechanism is fixed on the torsion mechanism; the base is provided with a frame on which a variable frequency motor is fixed;a small belt wheel is arranged on the output shaft of the variable frequency motor and transmitts power to the large belt wheel of the driving mechanism through the V-ribbed belt; a bedplate is fixedon the frame through a screw, and an outer frame is fixed on the bedplate. According to the invention, the automatic compensation of the test torque is realized; the testing machine can monitor in real time, judge when a product is invalid and realize automatic shutdown in a durability test; the measurement error caused by the clearance between the spline shaft and the spline hole of the tested workpiece is eliminated in the experimental process; the testing machine is simple and novel in structure and convenient in operation.

Owner:ZHEJIANG TIELIU CLUTCH

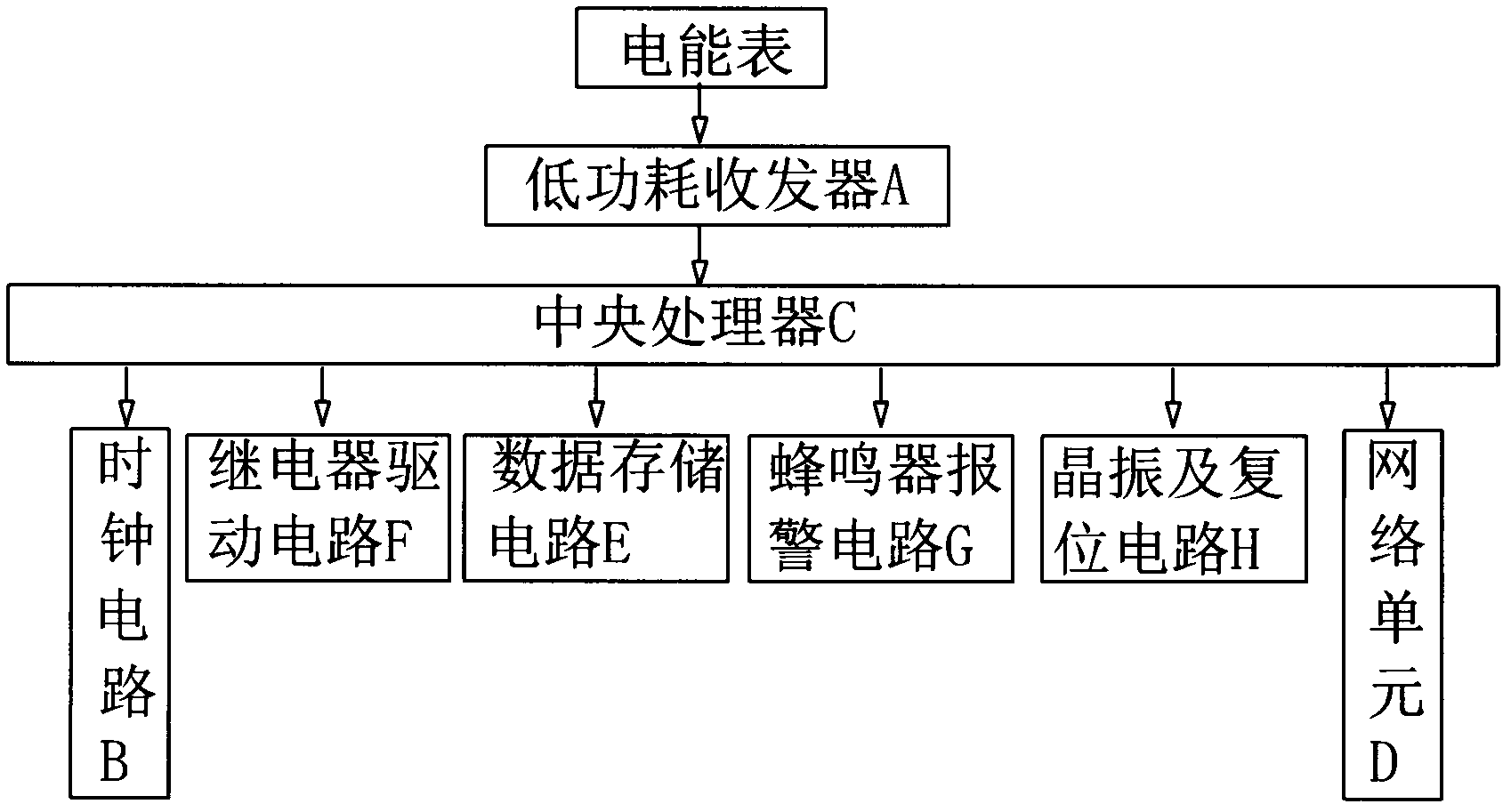

Building energy-saving monitoring data acquisition device

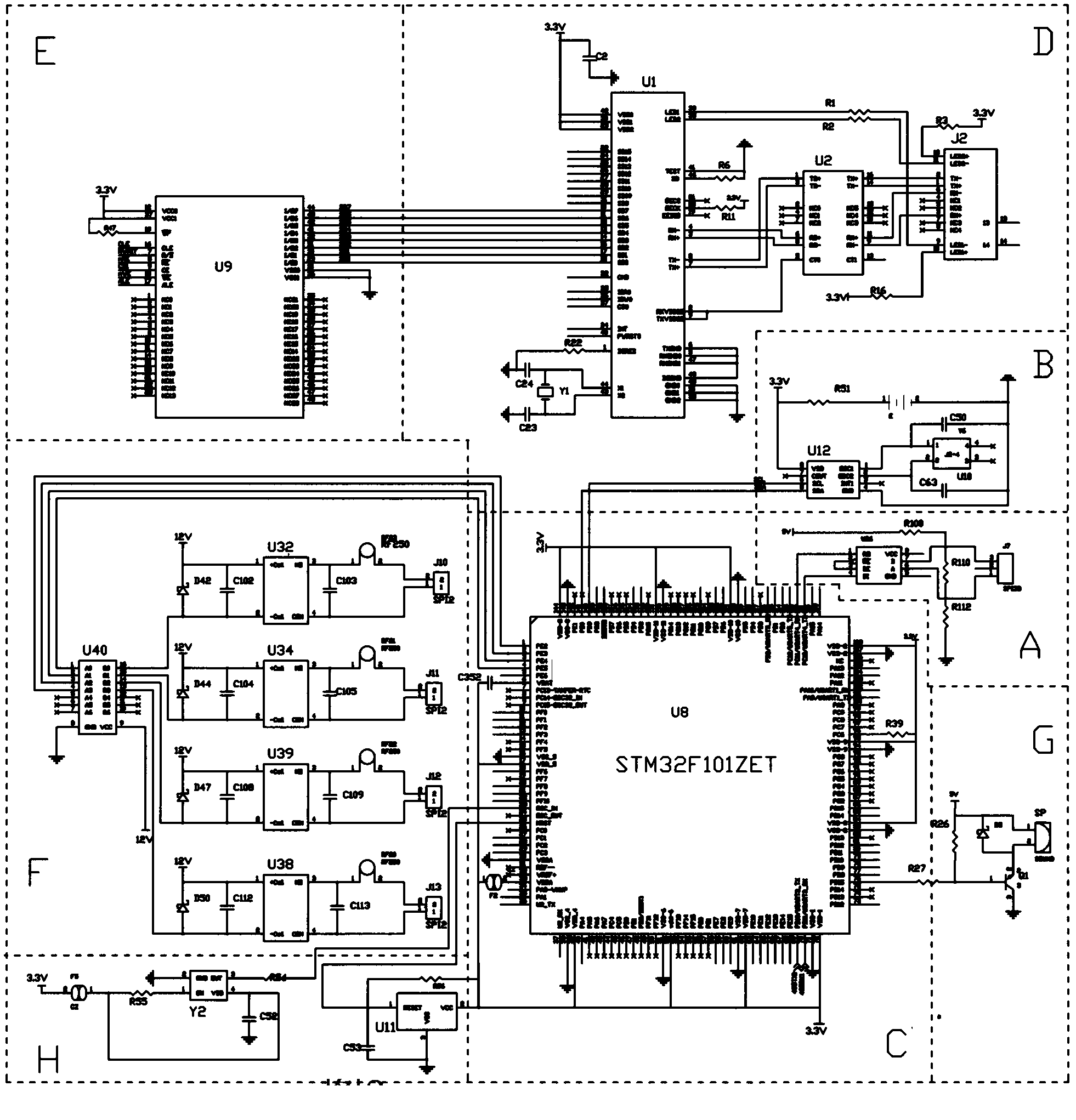

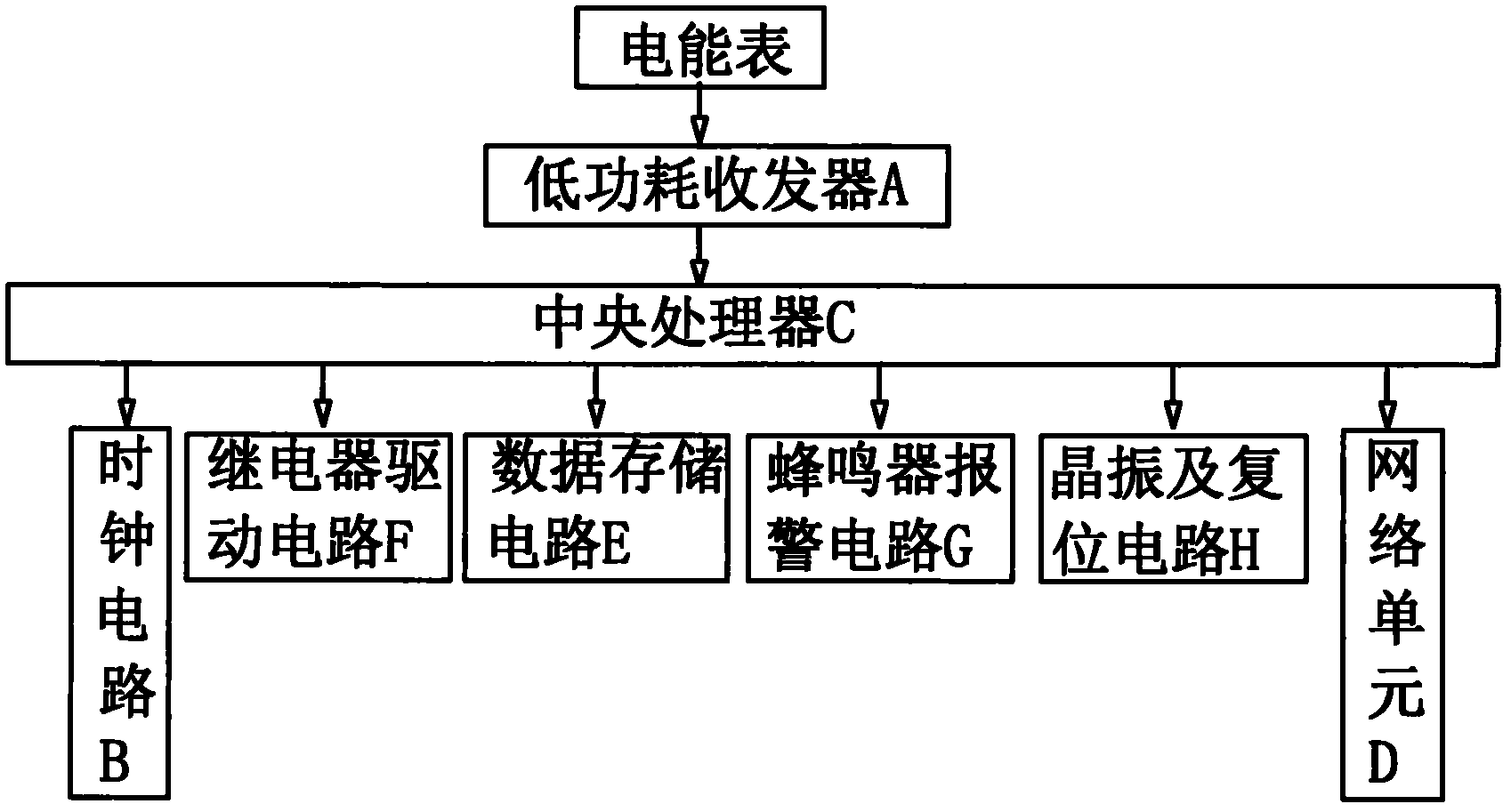

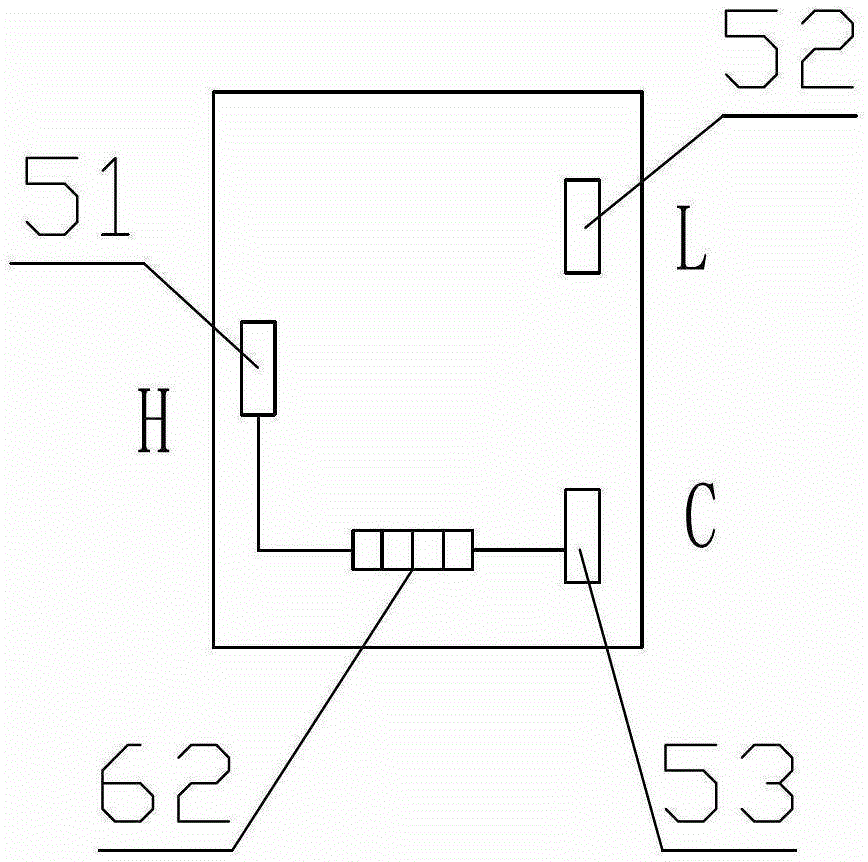

InactiveCN102568185ARealize data validity verificationRealize multiple automatic compensation functionsElectric signal transmission systemsMonitoring dataTransceiver

The invention discloses a building energy-saving monitoring data acquisition device. The structure of the data acquisition device consists of a low power consumption transceiver A, a clock circuit B, a central processing unit C, a network interface circuit D, a storage circuit E, a relay circuit F, a buzzer circuit G, a reset circuit and a crystal oscillator circuit H, wherein the low power consumption transceiver A, the central processing unit C, the network interface circuit D and the storage circuit E form a main circuit; the relay circuit F and the buzzer circuit G provide an alarm function for the data acquisition device; and the reset circuit and the crystal oscillator circuit H provide a necessary support for a singlechip processing unit. The arithmetic unit consisting of the conventional analog circuit is substituted by adopting the central processing unit, so that validity check and multiple automatic compensating functions of data are realized, high-precision monitoring of the data is realized, the problems of the conventional data acquisition device on the aspects of stability, reliability, measurement precision and the like are solved, and the protective capacity of the data acquisition device under over-current and over-voltage conditions is perfected.

Owner:高鹤

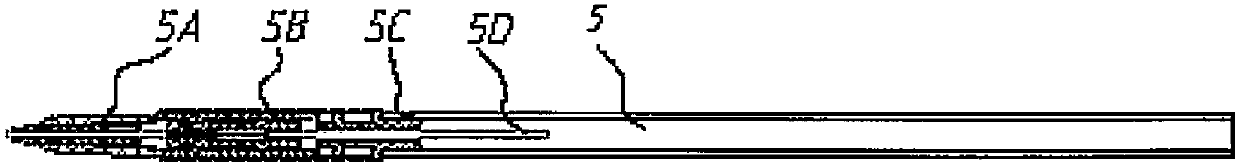

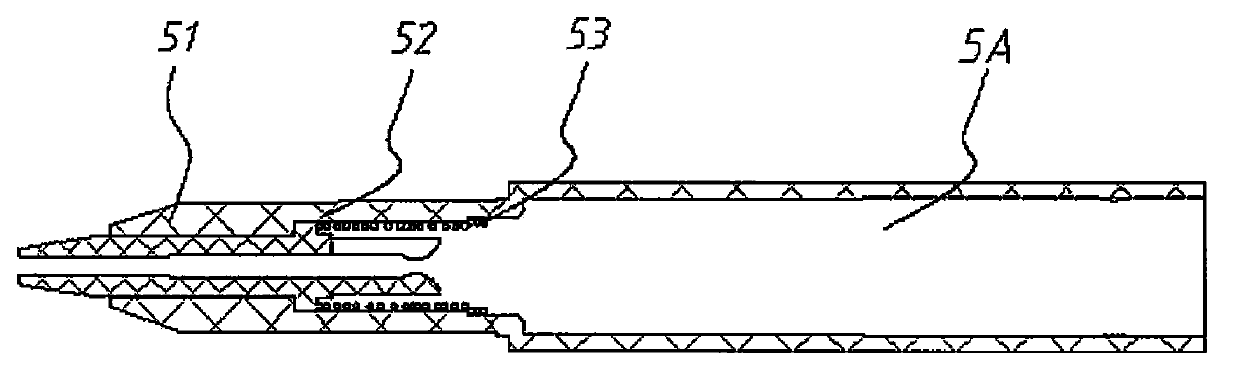

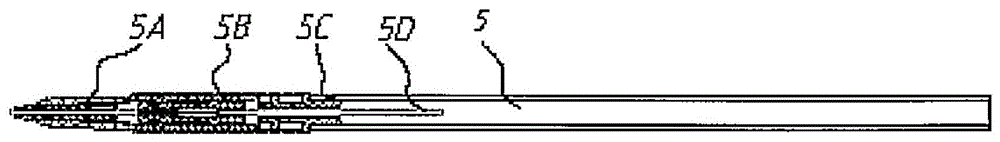

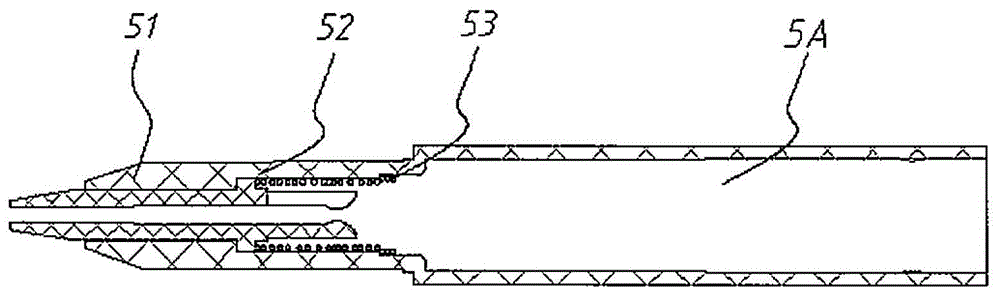

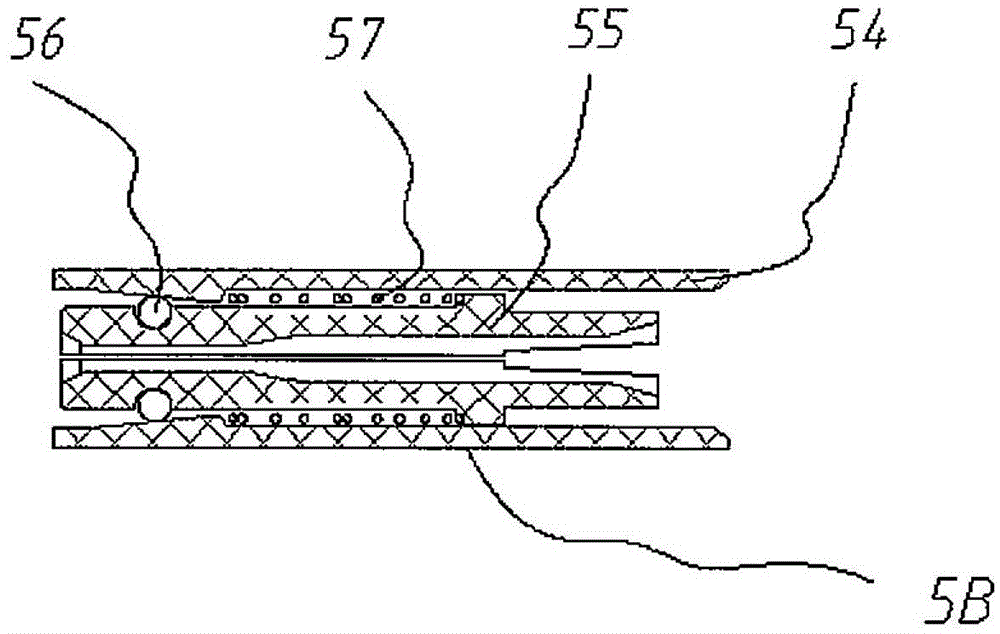

Fully-automatic mechanical pencil lead and lead-replaceable fully-automatic pencil

ActiveCN103963513ARealize automatic compensation functionPlay a protective effectPropelling pencilsEngineeringSteel ball

The invention provides a fully-automatic mechanical pencil lead and a fully-automatic pencil with the same. The fully-automatic mechanical pencil lead comprises a sharp sleeve part, a body part and a lead storage part, the sharp sleeve part comprises a sharp sleeve, a movable damping part mounted in the sharp sleeve and a damping spring sleeving the movable damping part, and the body part is mounted in the sharp sleeve part and comprises a retainer, a clamping piece arranged in the retainer, a clamping piece spring sleeving the clamping piece and steel balls movably mounted close to the front end of the clamping piece. The lead storage part comprises a lead storage tube and a connecting portion connected with the same, and the connecting portion is connected with the rear end of the sharp sleeve part and matched with the rear end of the body part. One pencil lead penetrates the lead storage tube and the connecting portion, enters the clamping piece and penetrates out of the front end of the movable damping part for writing. The fully-automatic pencil has the advantages that the worn pencil lead can be compensated automatically during writing, and the mechanical leads of the fully-automatic pencil can be replaced mutually.

Owner:SHANGHAI M&G STATIONERY INC

Friction transmission stepless speed change device

ActiveCN108708947APrecise control processGuaranteed reliabilityGearingGearing controlTransmission systemEngineering

Owner:XUZHOU COLLEGE OF INDAL TECH

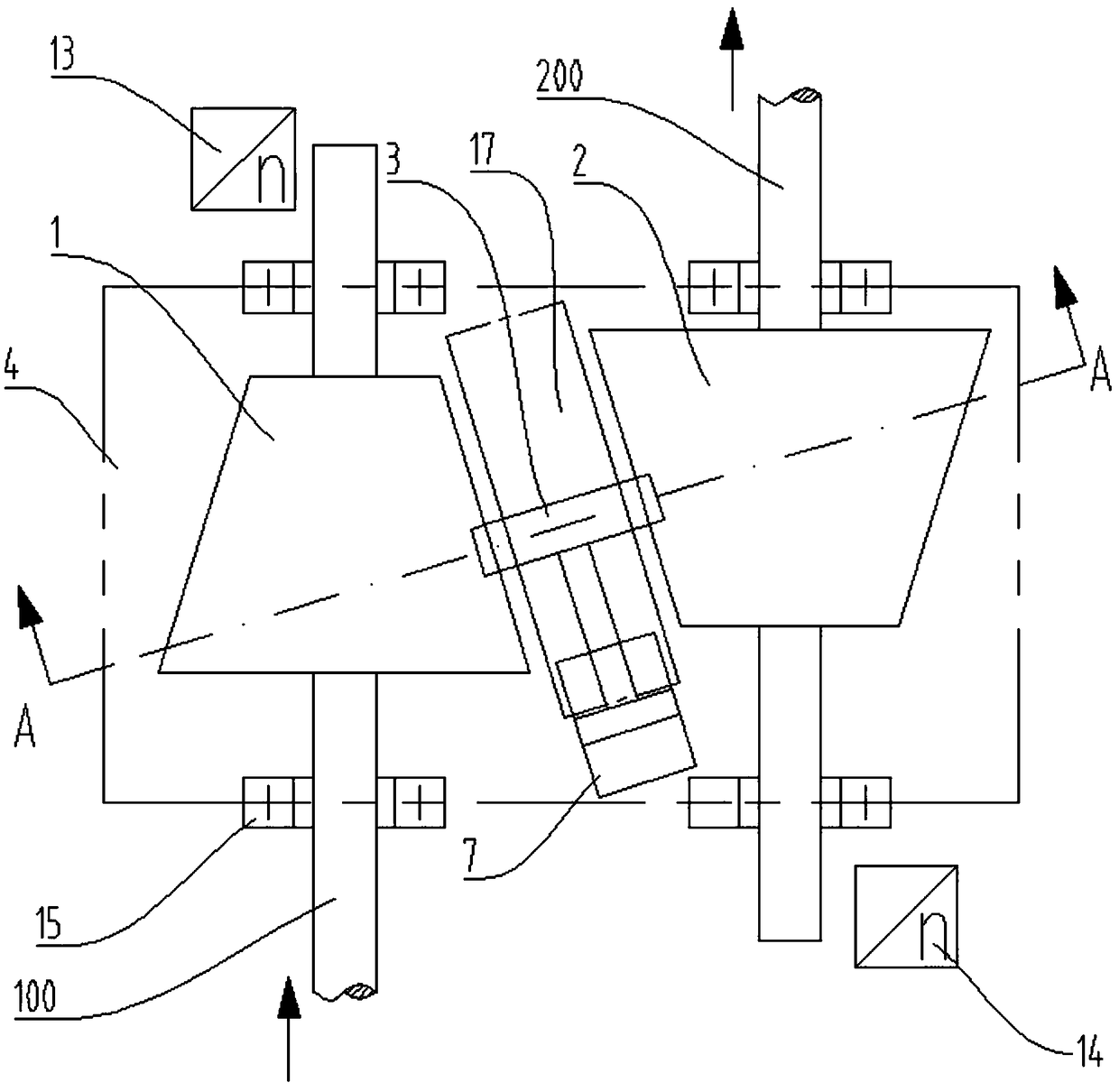

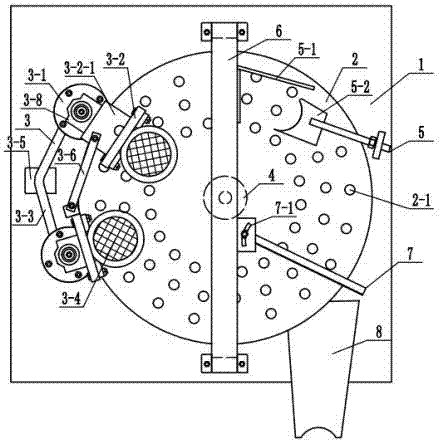

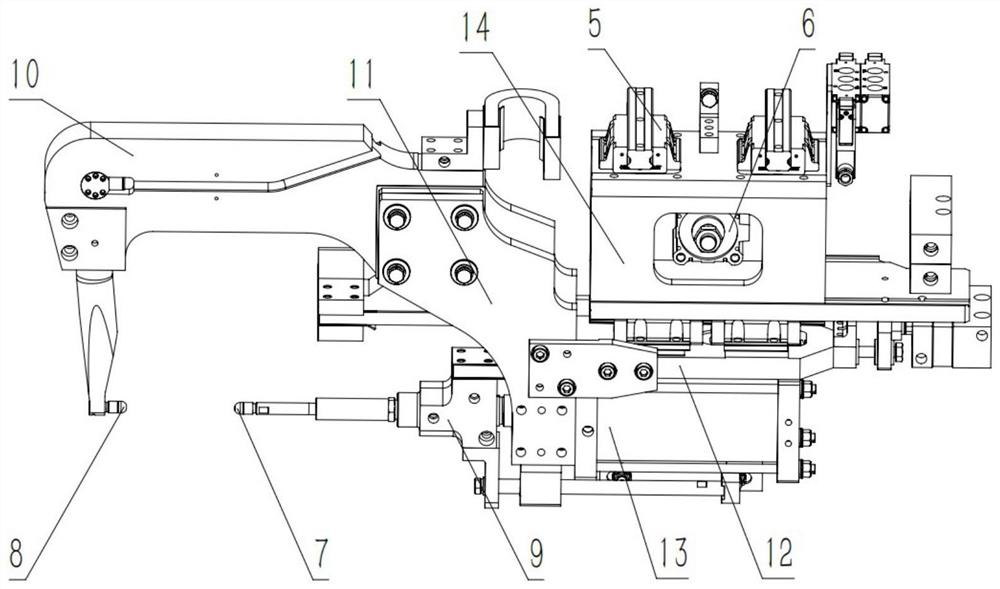

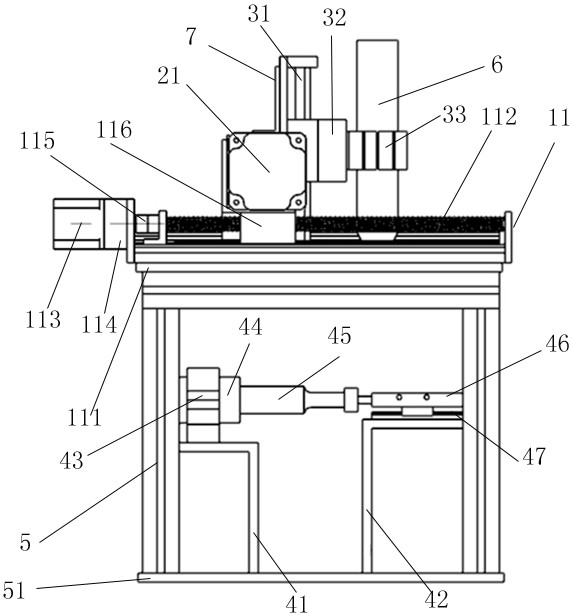

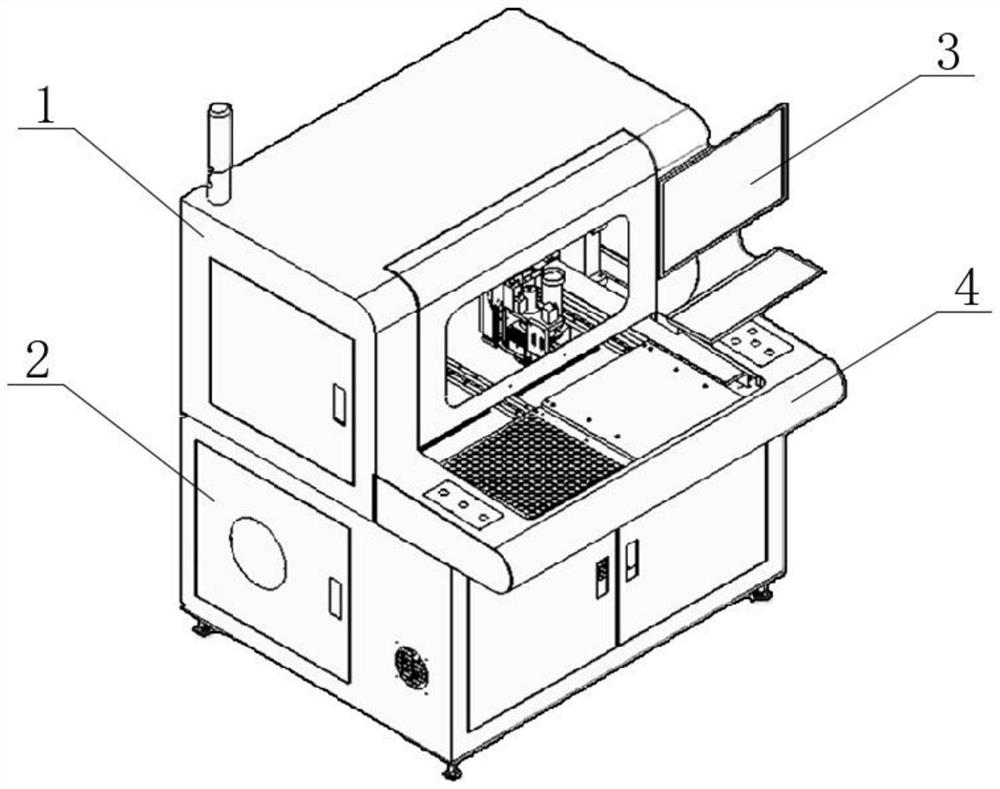

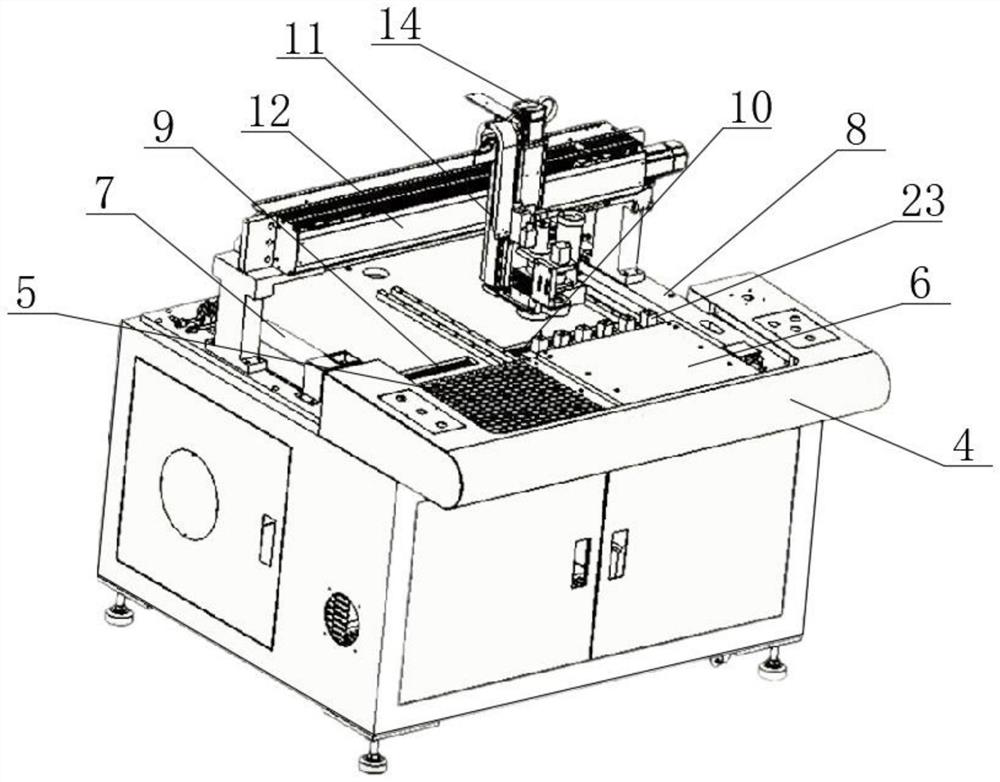

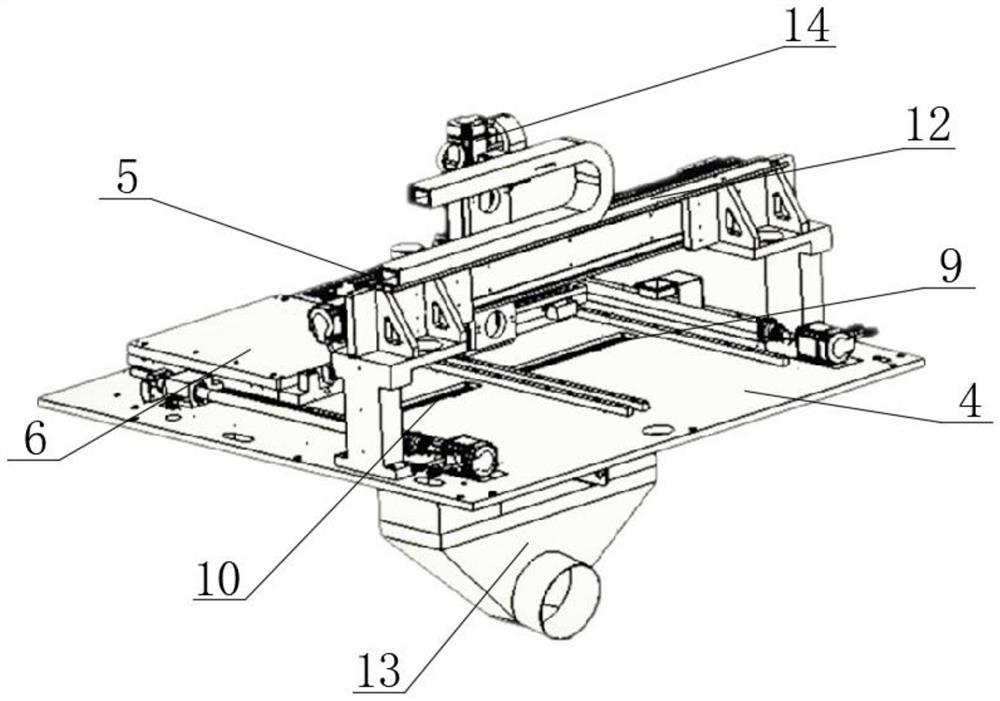

Automatic saw blade polishing machine

PendingCN107214614ARealize automatic compensation functionEnsure the consistency of polishing thicknessGrinding carriagesPolishing machinesPolishingElectric machinery

The invention provides an automatic saw blade polishing machine. The machine is characterized in that a turntable driving motor (4) is hoisted in the middle of the lower side of a lower platform (1), wherein the center of a turntable (2) is integrally fixedly connected with the turntable driving motor (4) and is positioned above the lower platform (1); a transverse crossing beam (6) is lengthways mounted on the lower platform (1) and is positioned right above the turntable (2); a grinder assembly (3) is mounted above the lower platform (1) and positioned at the left side of the transverse crossing beam (6); a circular arc shaped baffle plate (5-2) of a limiting assembly (5) is mounted on the lower platform (1) and positioned above the turntable (2); a V-shaped baffle plate (5-1) is fixedly mounted at the right side of the transverse crossing beam (6); a shifting baffle plate (7) is mounted at the right side of the transverse crossing beam (6) and positioned right above the turntable (2); a discharging groove (8) is mounted at the lower right corner of the lower platform (1). The machine is simple in structure, and high in automation degree; materials can be continuously fed through the turntable, and inside and outside grinding motors can increase the working efficiency, and thus the polishing quality can be ensured.

Owner:蒋南

Sealing device with automatic compensation function

PendingCN111188904ACompact structureExtended seal lifeEngine sealsPipe-jointsThermodynamicsProcess engineering

Owner:四川鼎志能源科技有限公司

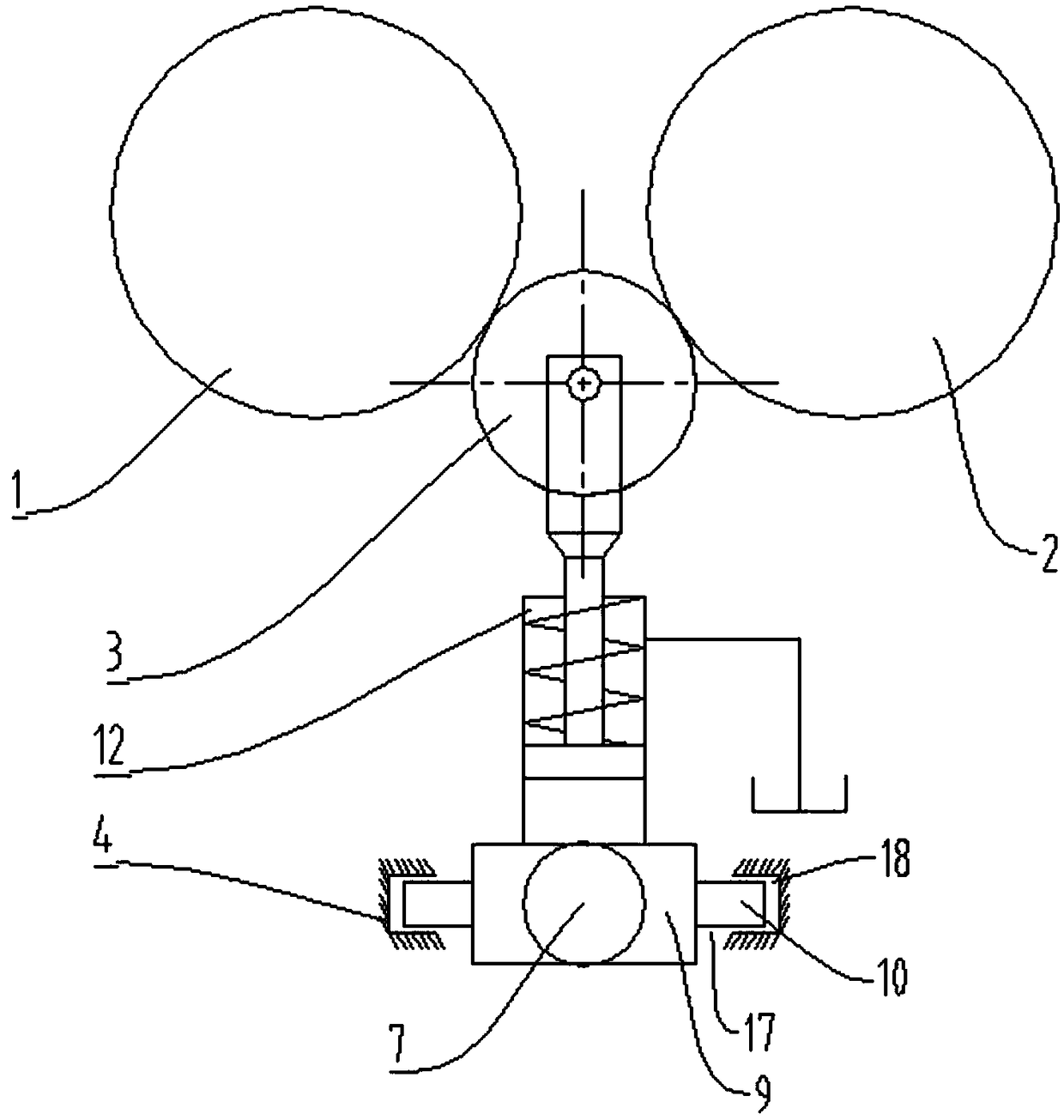

Long spring horizontal grinder and operation process thereof

PendingCN111421407AGuaranteed uniformityLower the altitudeGrinding feed controlAutomatic grinding controlEngineeringGrinding wheel

The invention relates to a long spring horizontal grinder. The long spring horizontal grinder includes a base; a clamping mechanism, a first grinding mechanism, a second grinding mechanism and an adjusting mechanism arranged on the base; the first grinding mechanism and the second grinding mechanism are separately located on both sides of the clamping mechanism; the clamping mechanism includes a support plate and a first driving mechanism; the support plate is used for fixing a long spring, and the two ends of the long spring separately extend out from the support plate; the first grinding mechanism includes a first grinding wheel and a second driving mechanism; and the second grinding mechanism includes a second grinding wheel and a third driving mechanism. During operation, the first grinding wheel, the second grinding wheel and the support plate rotate simultaneously, and the first grinding wheel and the second grinding wheel separately grind the two end faces of the long spring extending out from both sides of the support plate. In the invention, the long spring is horizontally fixed on the support plate; therefore, the height of the grinder is not limited by the length of thelong spring, and the height of the grinder is greatly reduced.

Owner:苏州切浦汽车零部件有限公司

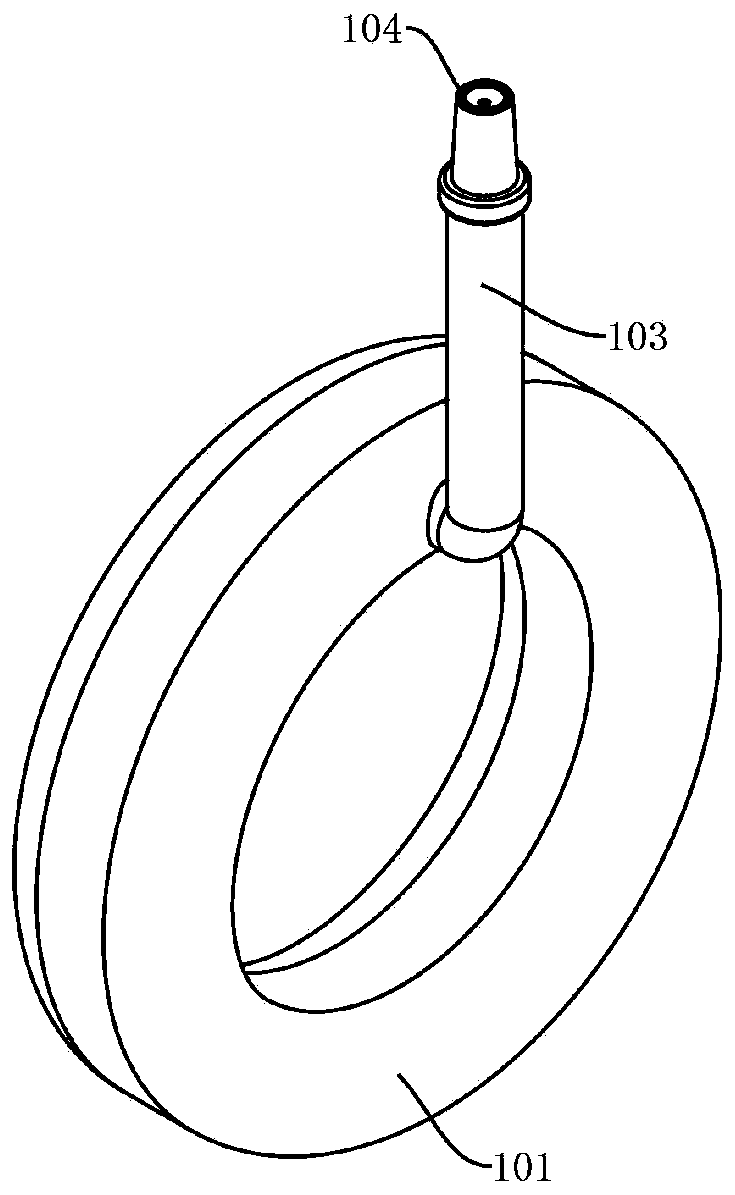

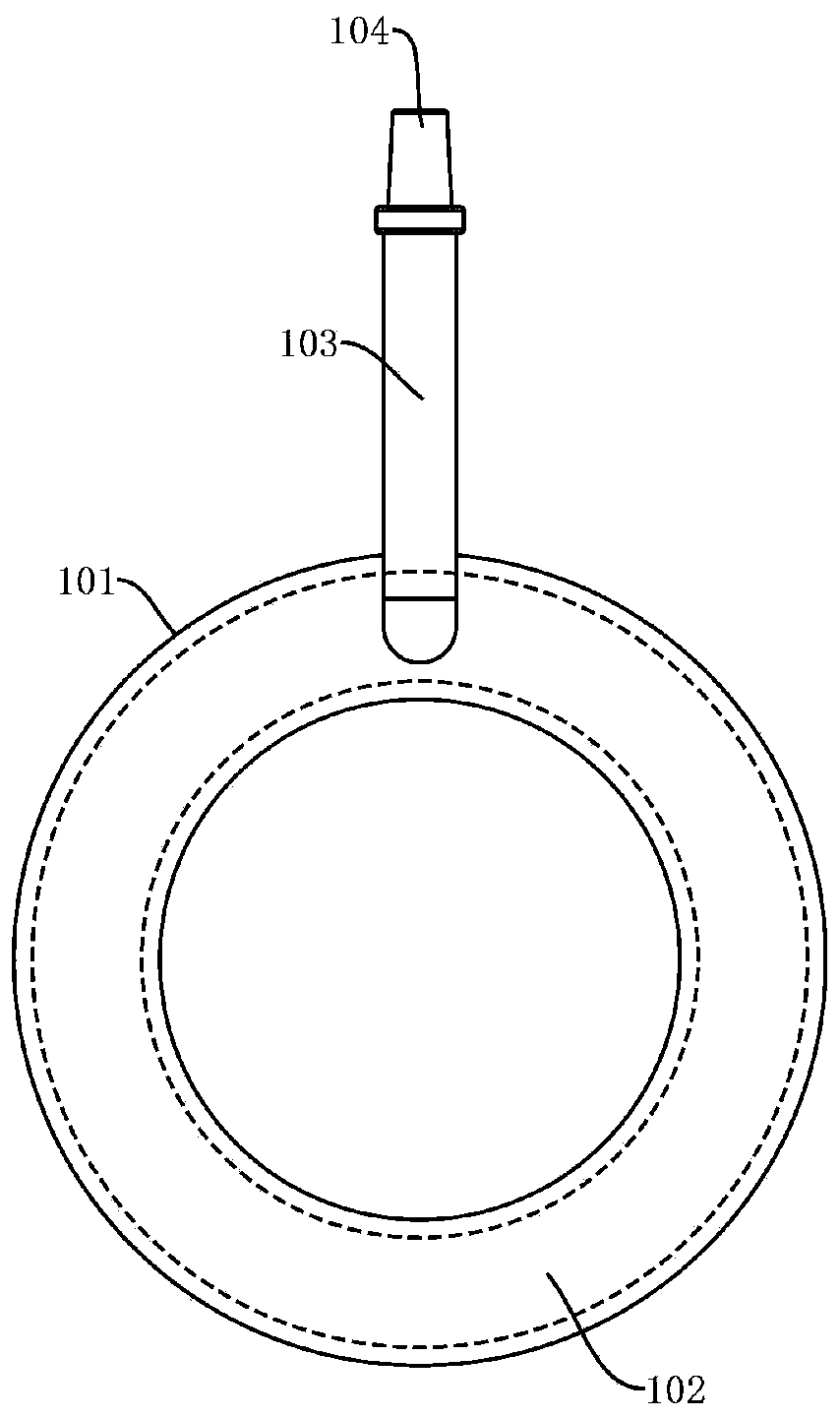

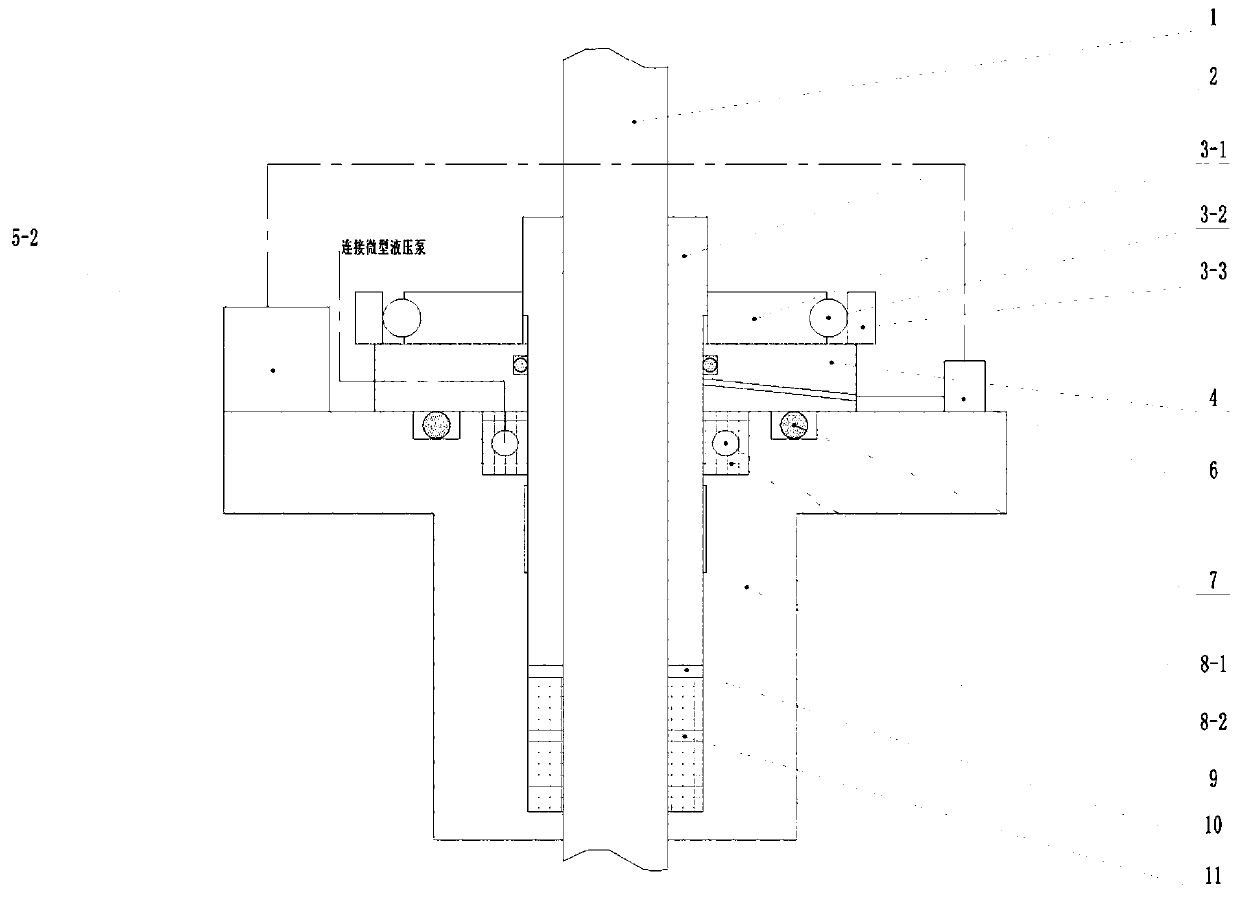

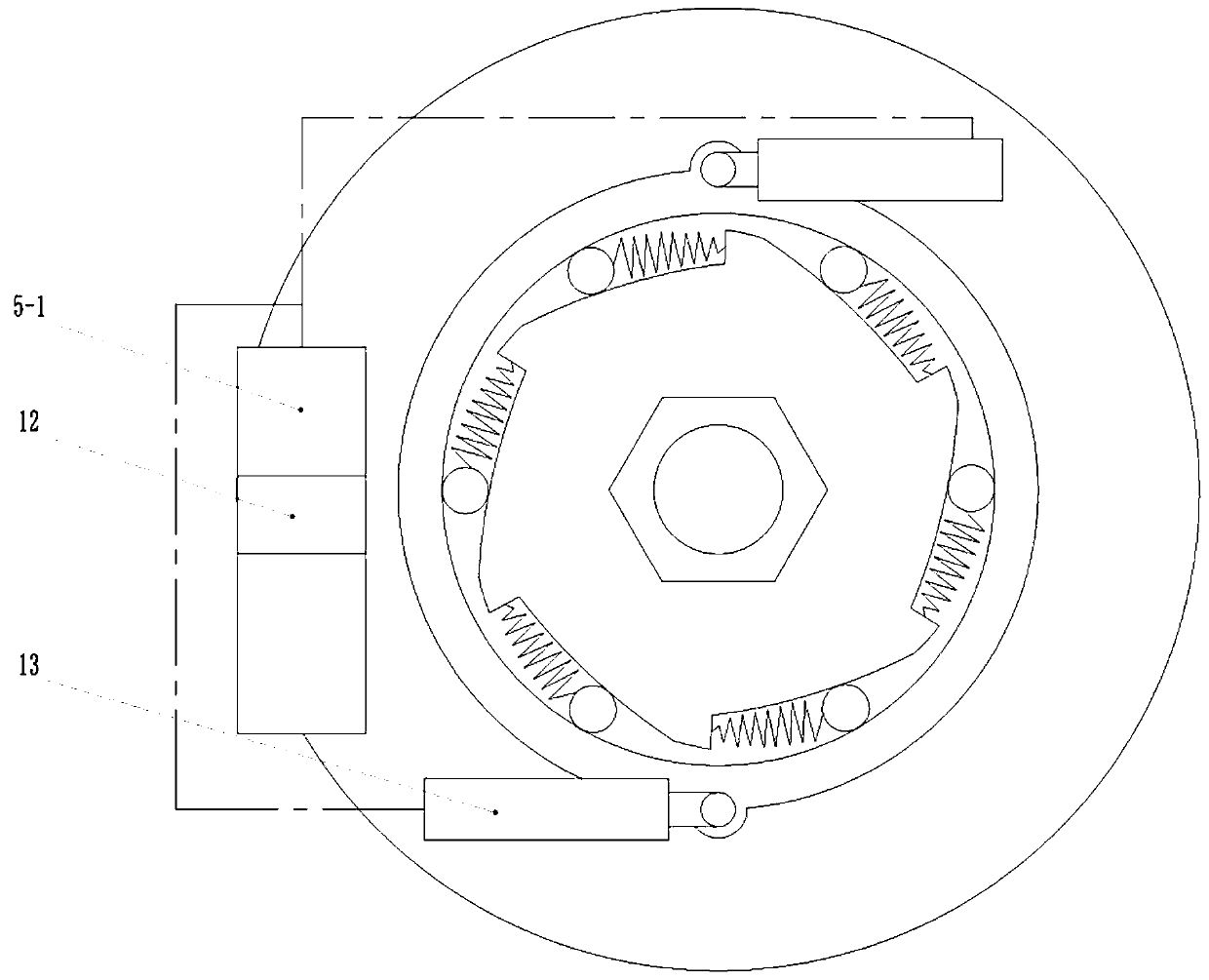

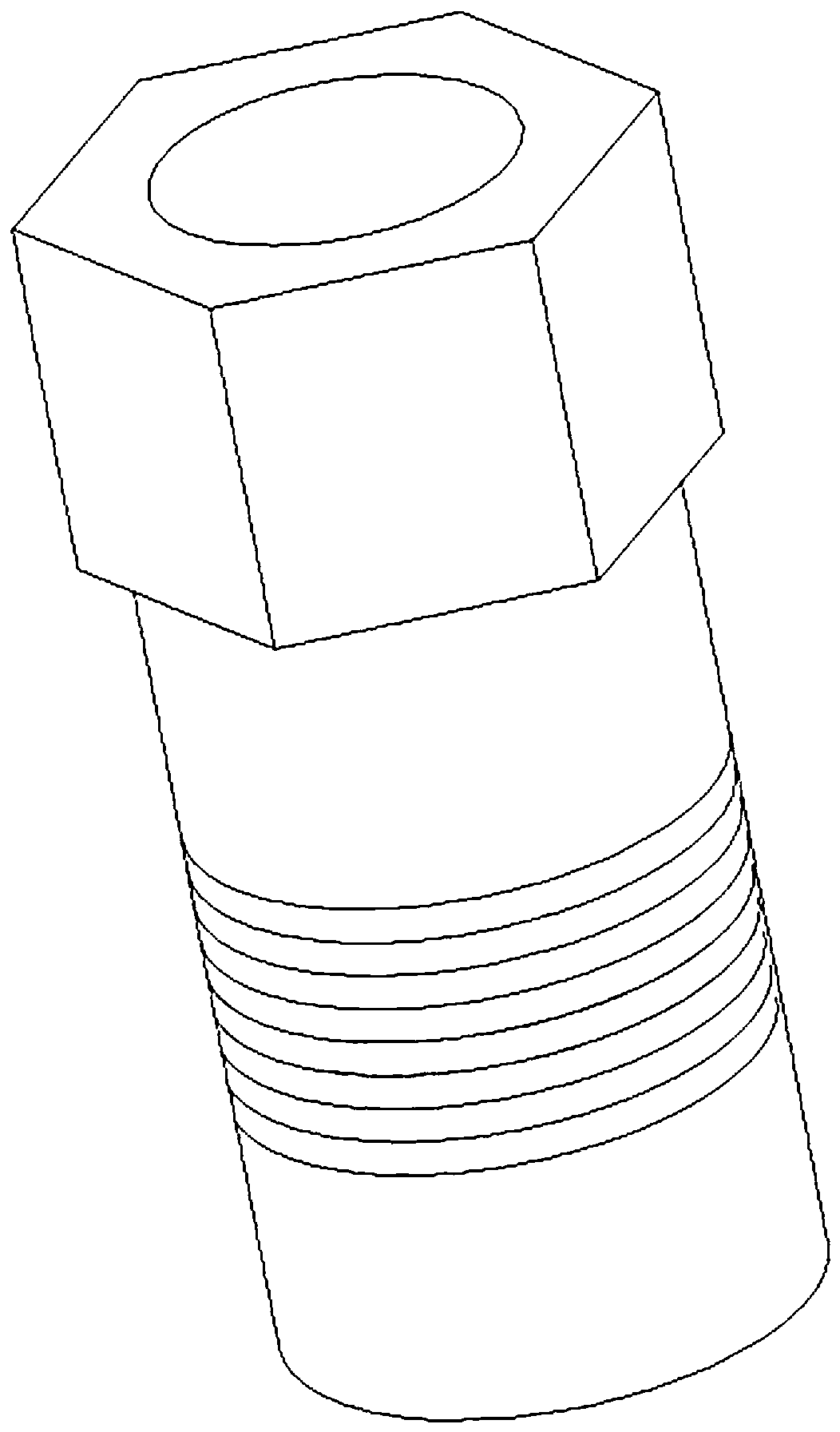

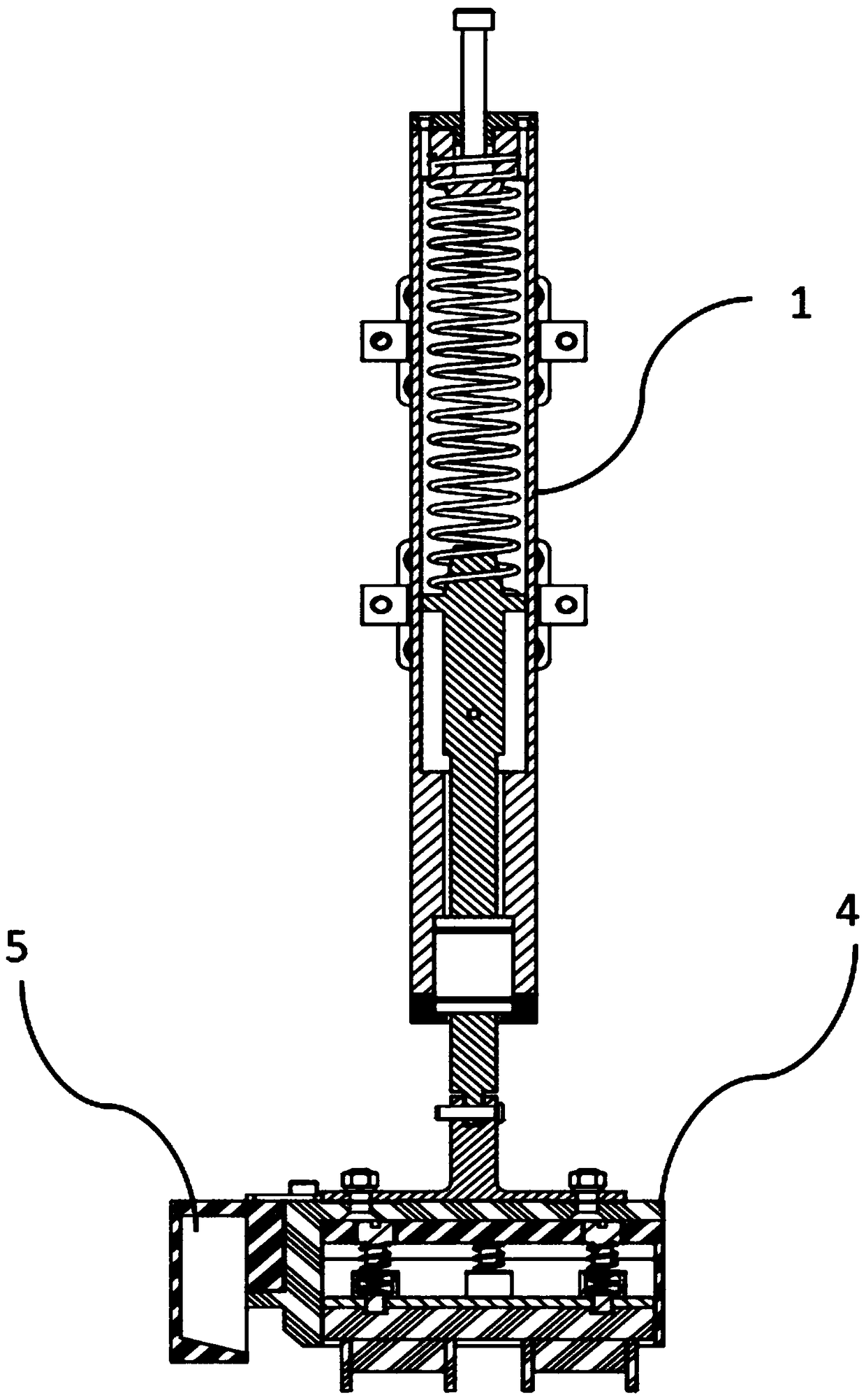

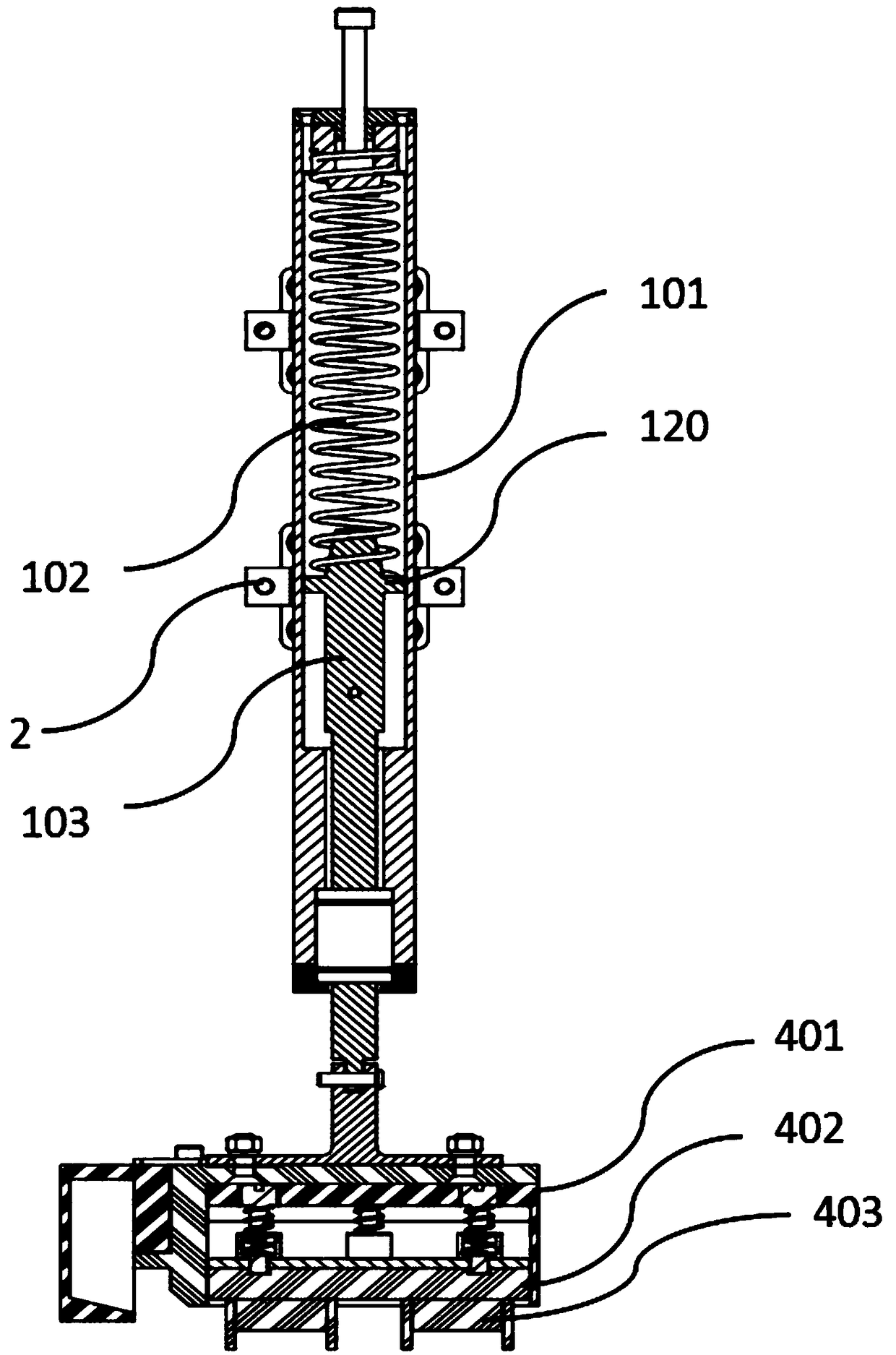

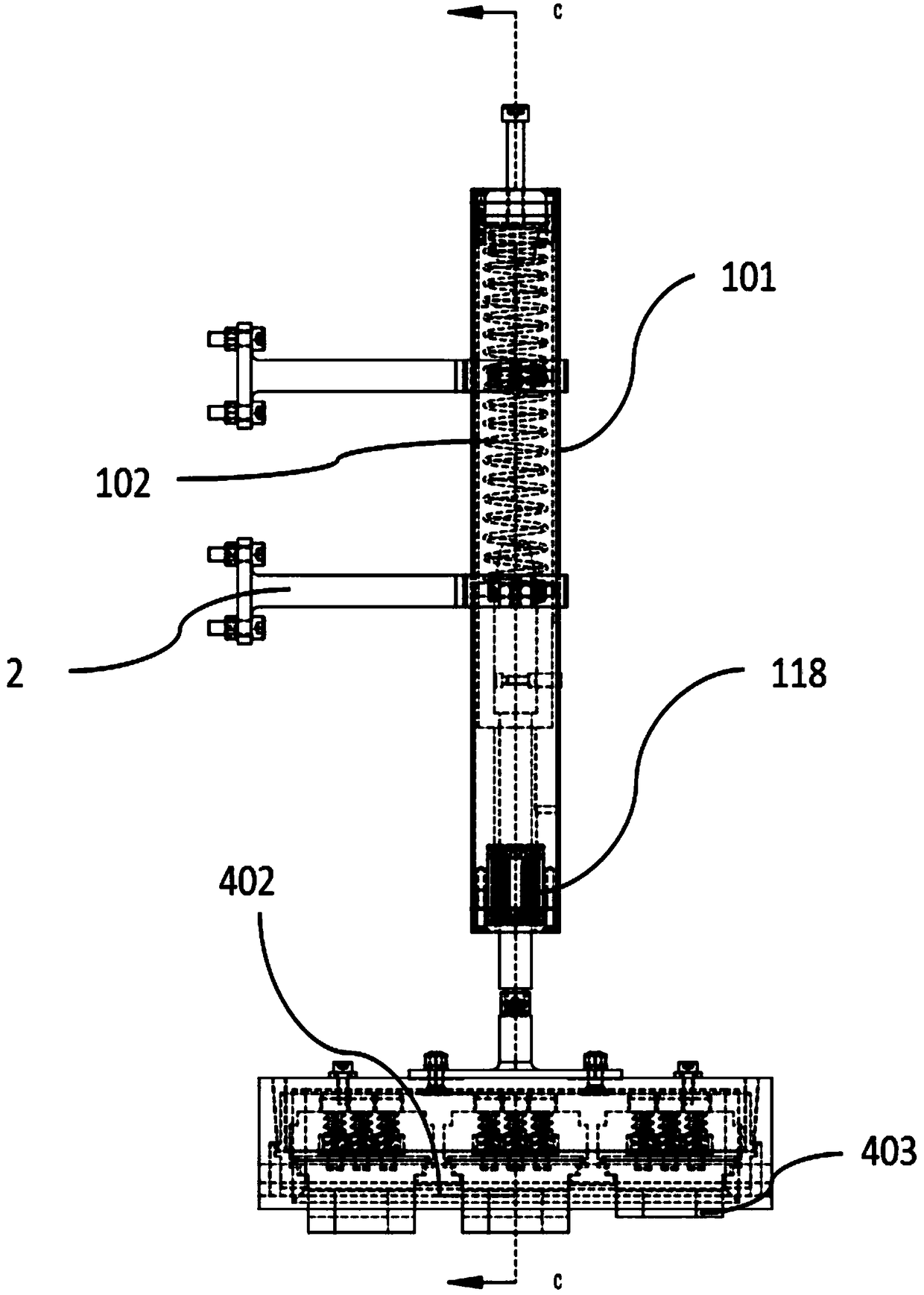

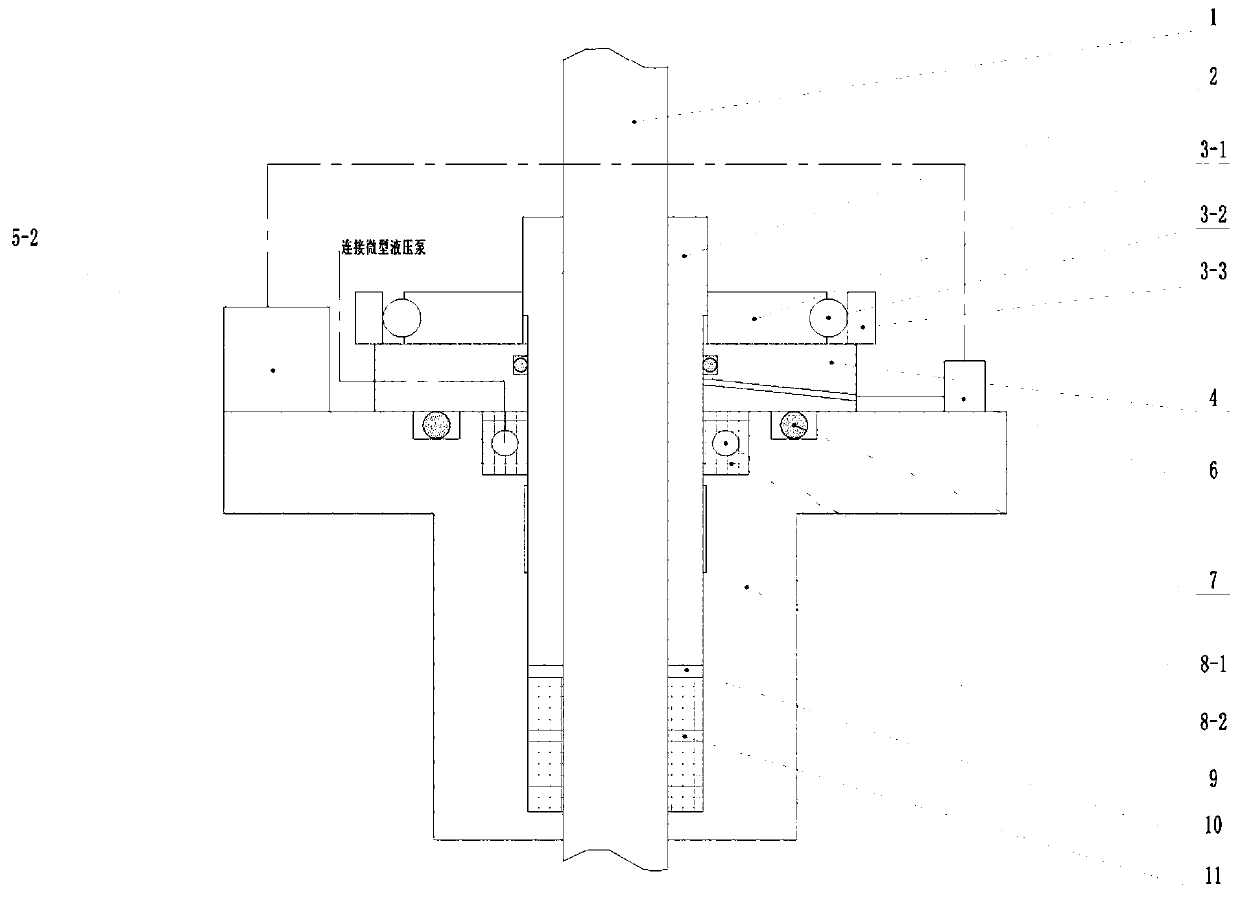

Automatic monitoring compensation and emergency device for valve rod seal

ActiveCN110195799AReal-time feedback of monitoring dataReduce wearSpindle sealingsDetection of fluid at leakage pointHydraulic cylinderDrive wheel

The invention discloses an automatic monitoring compensation and emergency device for valve rod seal, and relates to the field of valve rod seal. The automatic monitoring compensation and emergency device for valve rod seal sequentially comprises a valve body upper end, a soft filler, a metal ring and a valve rod from bottom to top, wherein a threaded filler compression piece is arranged at the upper end of the metal ring; the valve rod penetrates through the soft filler, the metal ring and the threaded filler compression piece; a mould pressing filler and a sealed O-shaped ring slot are arranged at the top end of the valve body upper end; a medium leakage monitoring ring is arranged at the upper ends of the mould pressing filler and the sealed O-shaped ring; a medium leakage monitoring sensor is arranged on a monitoring port of the medium leakage monitoring ring; the medium leakage monitoring ring is connected with a programmable logic controller; a drive wheel, a rolling steel ball and a driven ratchet wheel are arranged at the upper end of the medium leakage monitoring ring; the drive wheel is connected with a micro hydraulic cylinder; the driven ratchet wheel and the threaded filler compression piece are in clearance fit; and the micro hydraulic cylinder is connected with a micro hydraulic pump and the programmable logic controller. The automatic monitoring compensation andemergency device for valve rod seal can realize the real-time monitoring on the valve rod seal leakage, and has the functions on automatically compensating a soft filler and emergently sealing in case of complete failure.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

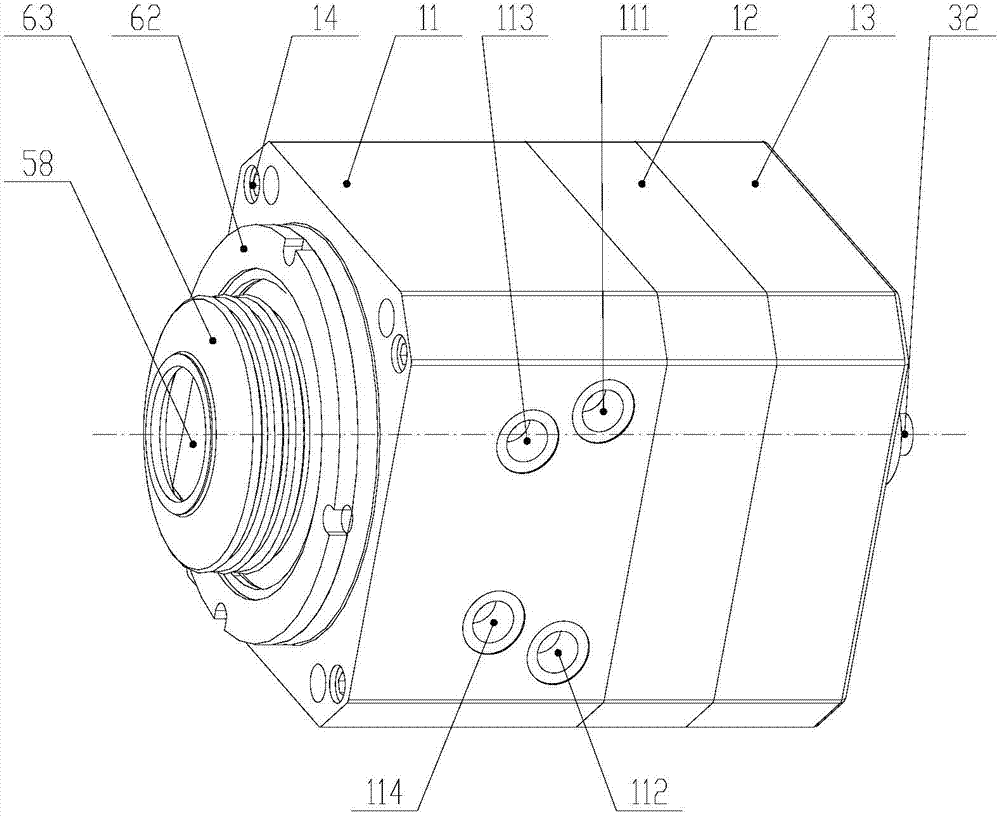

Adjustable oil pressure buffer with automatic compensation function

ActiveCN107917162AIncrease volume capacityAdjust capacitySpringsLiquid based dampersSteel ballCheck valve

The invention provides an adjustable oil pressure buffer with an automatic compensation function. The adjustable oil pressure buffer can solve the problem that an existing adjustable oil pressure buffer cannot conduct self-adaptation adjustment. A flow adjusting rotary knob is rotationally arranged at the rear end portion of an outer pipe, and an axial step hole concentrically communicating with afirst axial runner is formed in a rear cover. A flow adjusting through hole communicating with the axial step hole is formed in the front end face of the rear cover around the periphery of a first steel ball check valve. A movable stop block is movably arranged in a front end hole of the axial step hole, and a spring assembly is arranged in a rear end hole. A hydraulic oil flow adjusting cavity is formed between the front end face of the movable stop block and the front end face of the axial step hole of the rear cover. The movable stop block is provided with a second axial runner concentrically communicating with the first axial runner, an adjusting ejector sheet is in threaded connection to the front end of the flow adjusting rotary knob and located on the rear end side of an inner pipe, and the front end and the rear end of the spring assembly abut against the movable stop block and the adjusting ejector sheet correspondingly.

Owner:C JAC IND CO LTD

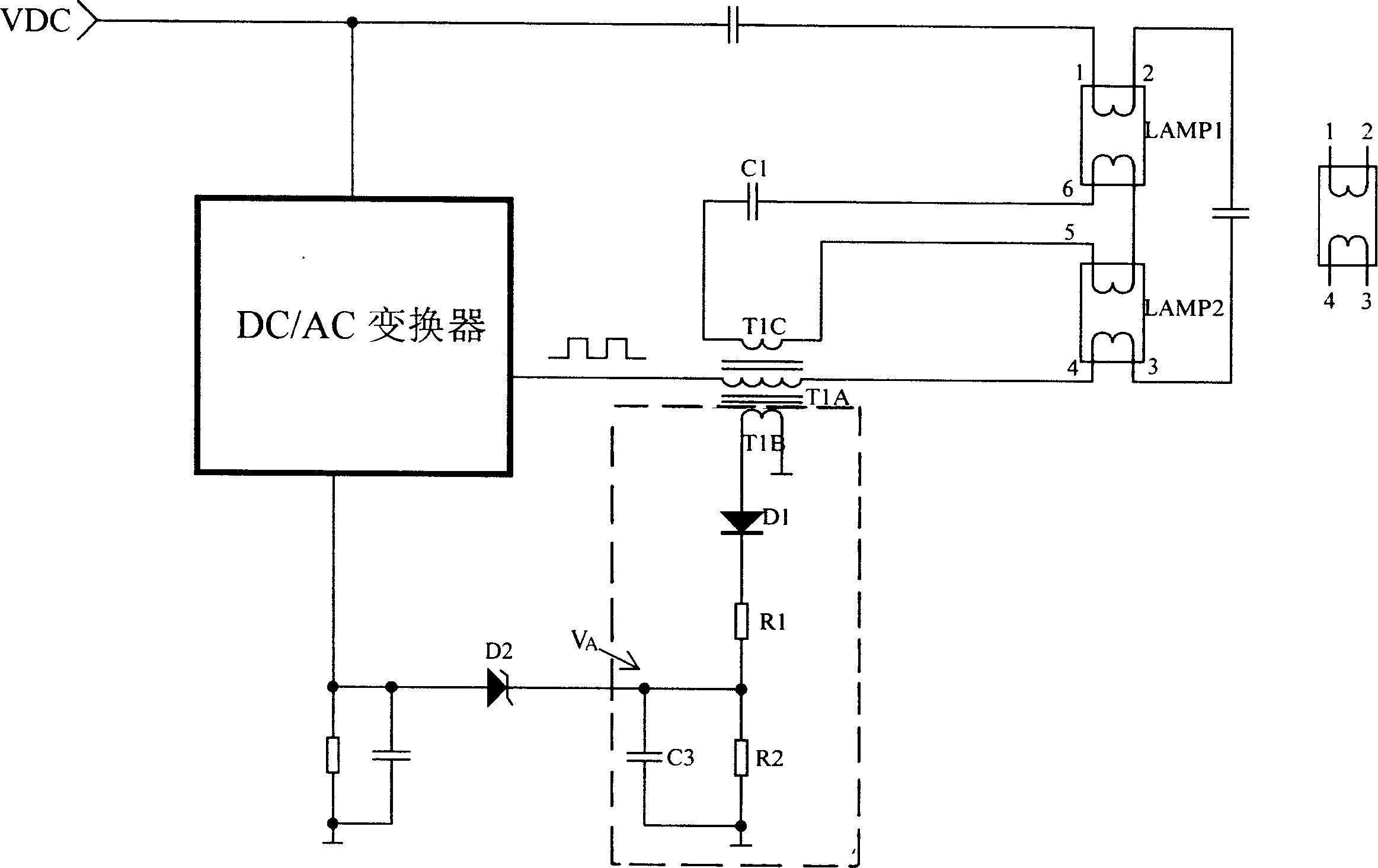

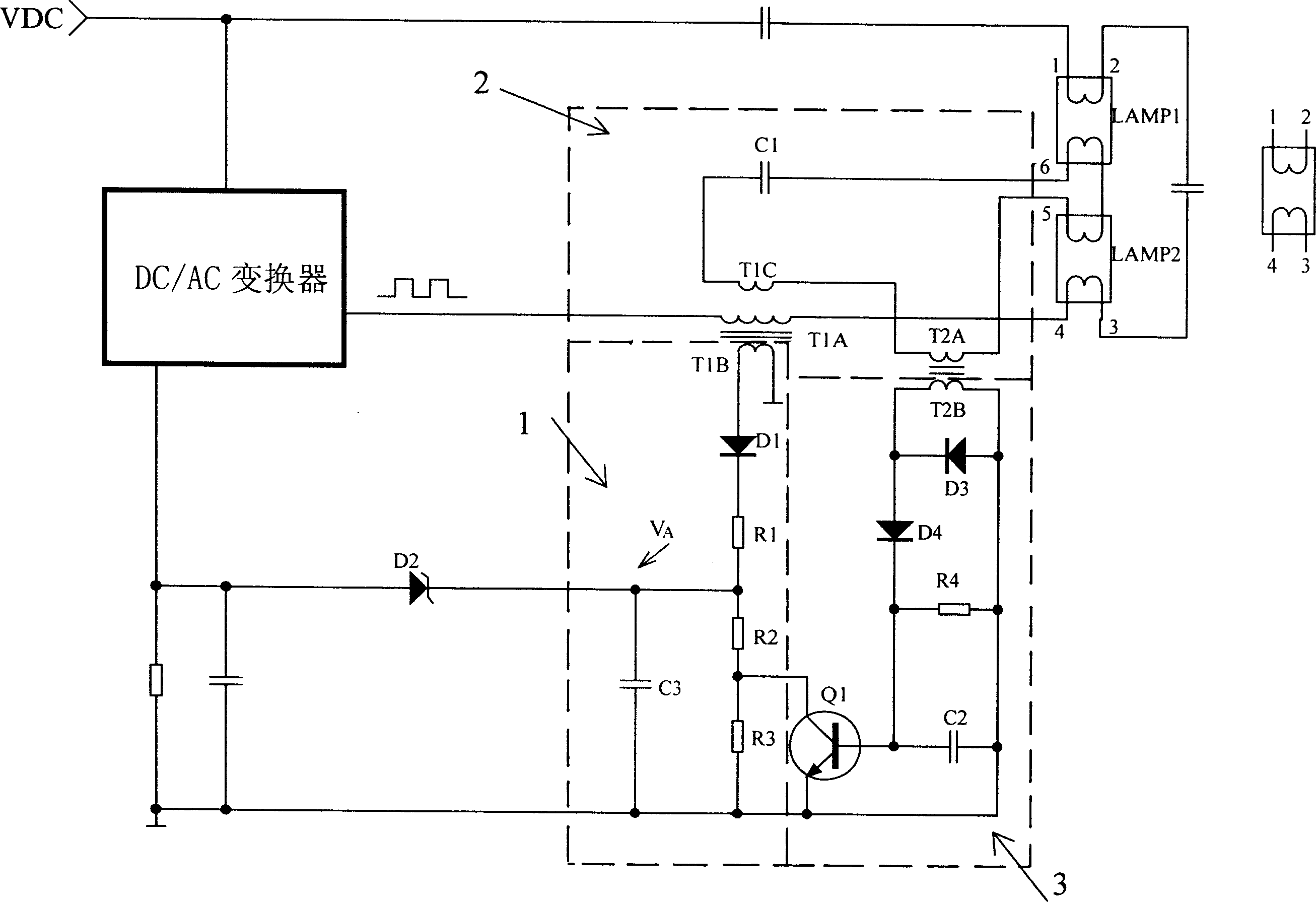

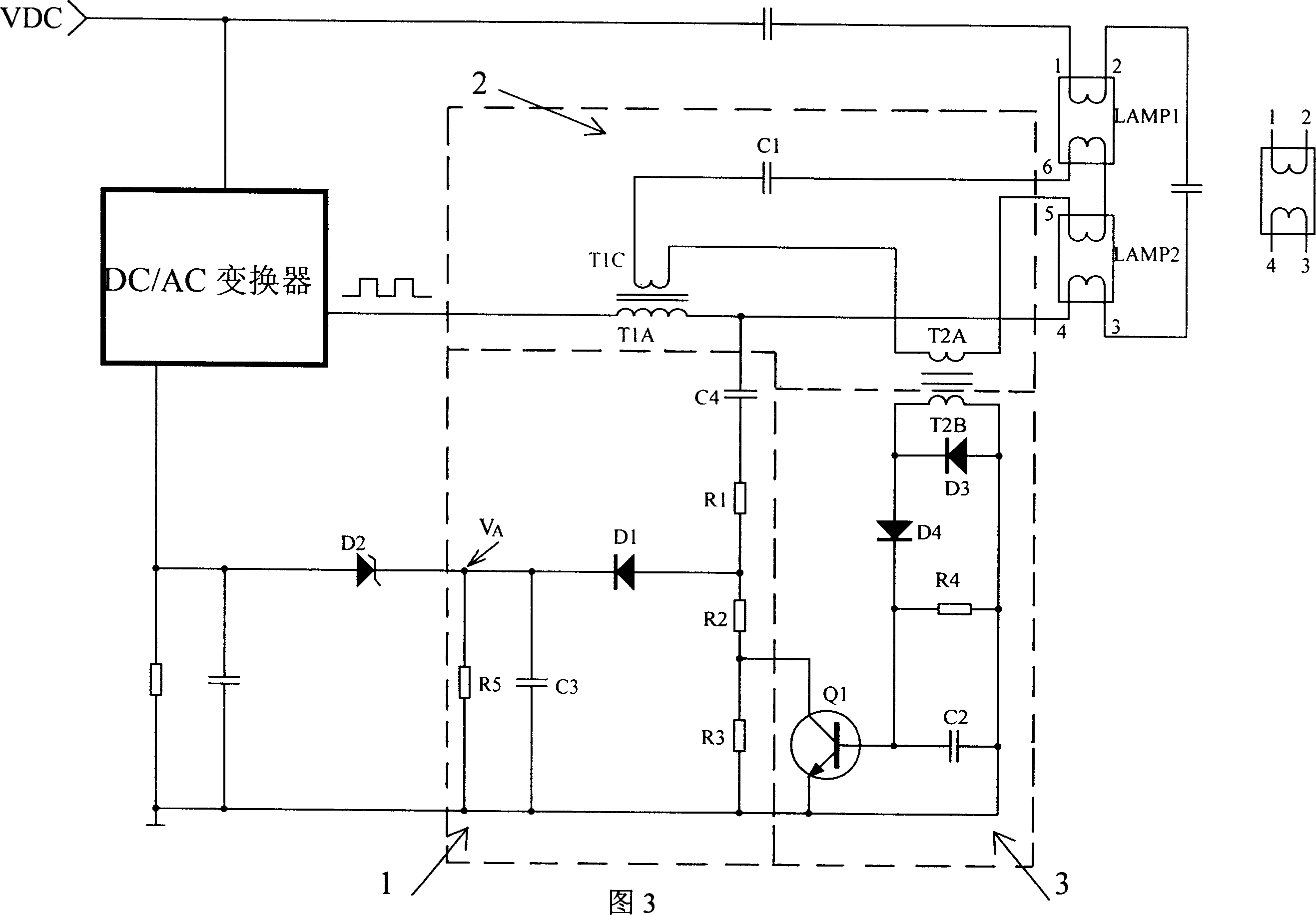

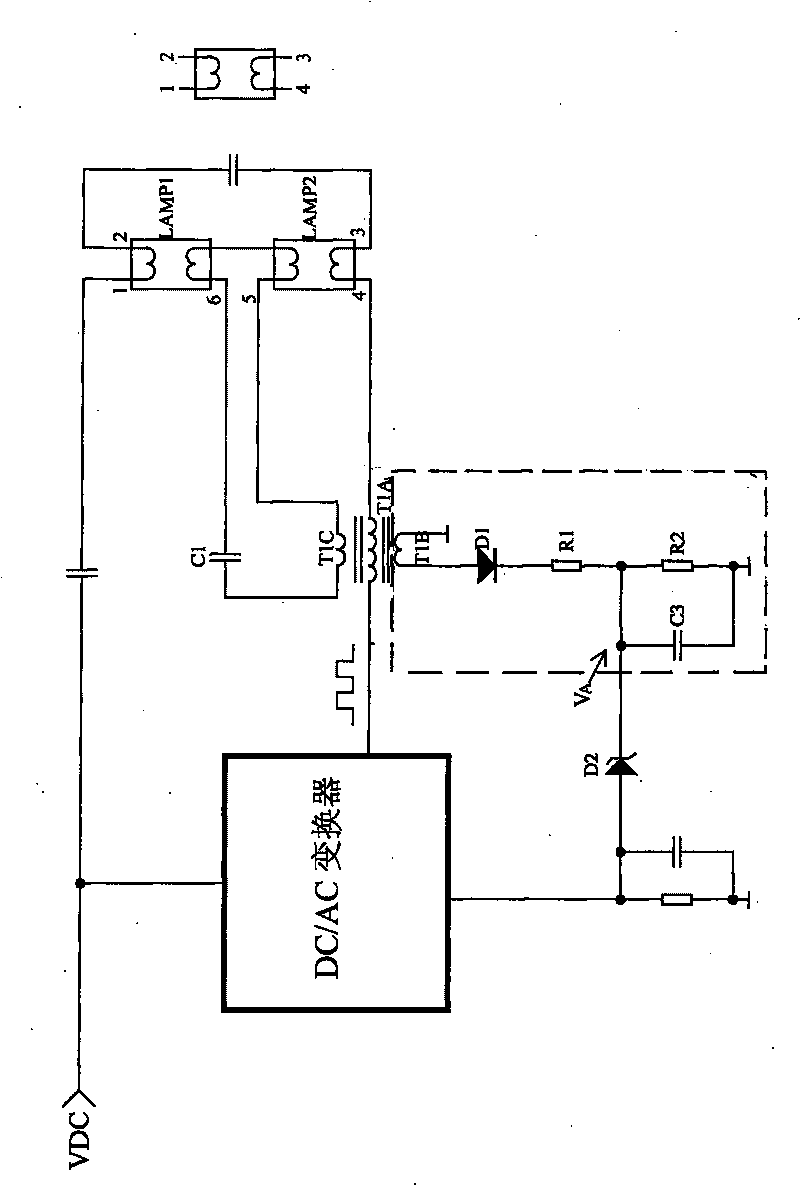

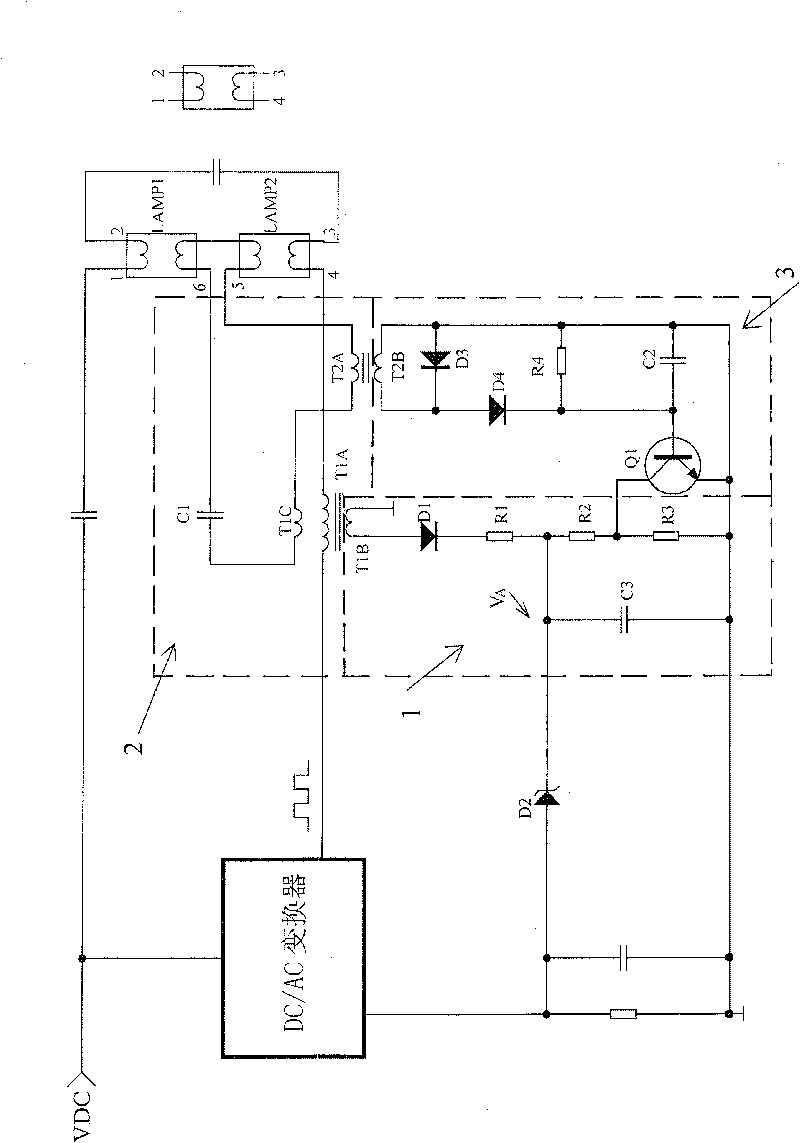

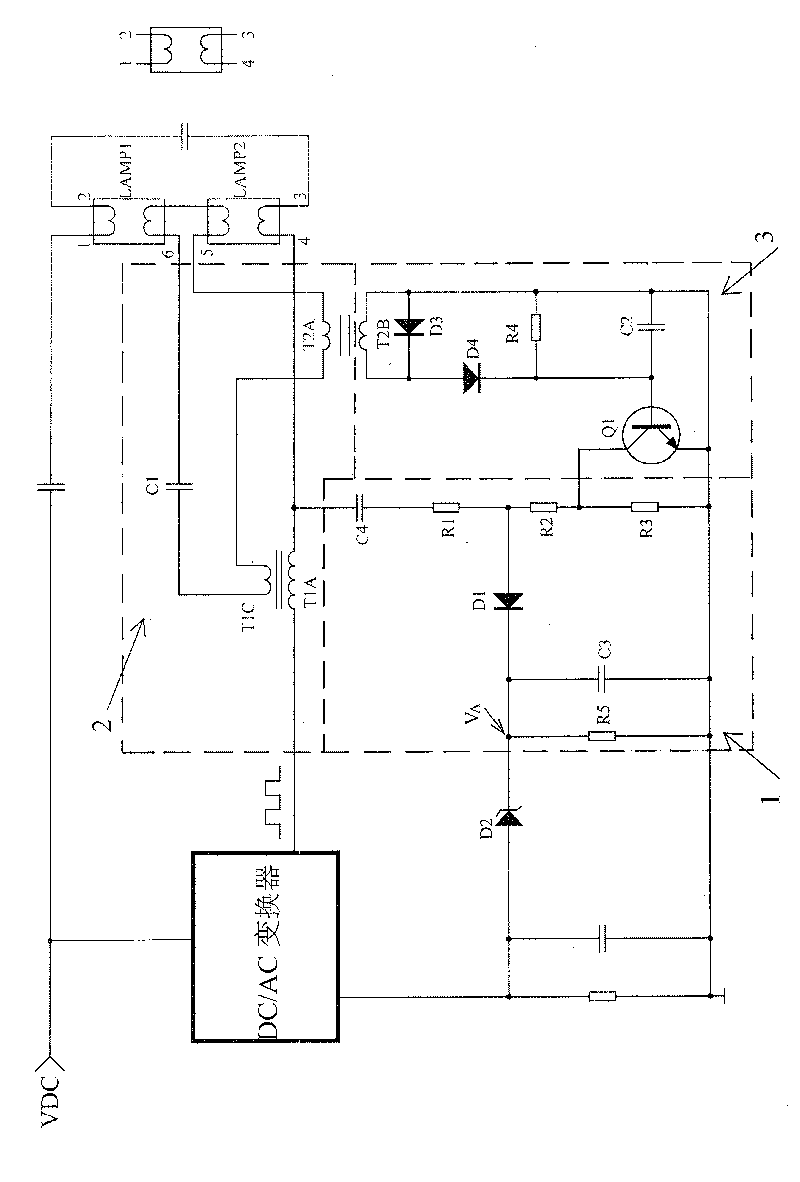

Automatic detecting and compensating circuit for single and double lamps

ActiveCN1822744ARealize automatic compensation functionElectrical apparatusElectric lighting sourcesElectrical ballastControl signal

Present invention discloses a single double lamp automatic-detection compensation circuit for fluorescent lamp electronic ballast. It includes abnormal signal detection abnormal signal detection circuit, single double lamp detection circuit single double lamp control circuit, wherein lamp detection circuit connected to filament leading out end, single double lamp control circuit receiving single double lamp detection circuit signal and outputting control signal, abnormal signal detection circuit set between electronic ballast output circuit and DC / AC convertor and receiving single double lamp control circuit control signal and in lamp tube disorder working outputting steady disorder signal protection voltage V to DC / AC convertor. Said invention can effectively solves guard signal compatibility problem in current technology and sensitivity problem to realize guard signal automatically compensating function in lamp tube disorder working or different loading condition.

Owner:DONGYANG TOSPO LIGHTING

Intelligent transmission apparatus for pH value of water

InactiveCN101343104BRealize plug and playRealize intelligenceWater/sewage treatment by neutralisationMaterial analysisWater qualityTransmitter

The invention develops a water quality pH value intelligent transfer device for intensive water quality monitoring applications, aiming at the status quo of urgent need of automatic water quality monitoring technique in intensive aquaculture in China. The intelligent transfer device integrates the water quality parameter signal conditioning technique and the transfer technique, and is directly input with signals of water temperature and pH value sensor probes, and is embedded with a high performance microprocessor, the device utilizes the self-calibration technique to realize the pH value automatic temperature compensation function on the basis of signal acquisition of probes, and also adopts an intelligent network interface model described in the IEEE1451 standard to realize the self-diagnosis and plug-and-play functions of an intelligent transmitter. The water quality pH transfer device is advanced to develop towards intelligence, networking and miniaturization, thereby raising the water quality monitoring level of intensive aquaculture.

Owner:CHINA AGRI UNIV

Plane guide rail cleaning device

InactiveCN109351687AWill not affect normal operationRealize automatic compensation functionCleaning using toolsRailway cleaningFixed frameRadian

The invention discloses a plane guide rail cleaning device. The plane guide rail cleaning device comprises a body mechanism, a body fixing frame and a cleaning flexible assembly. The body mechanism comprises a sleeve internally provided with a main elastic piece, a sliding rod is connected to the lower end of the main elastic piece and can freely slide in the sleeve, and the inner diameter of thelower half section of the sleeve is matched with the diameter of the sliding rod. One end of the body fixing frame sleeves the sleeve, and the other end of the body fixing frame is fixedly connected with drive equipment. The cleaning flexible assembly is connected with the sliding rod in a replaceable manner and comprises a cleaning module shell, and the cleaning module shell is internally provided with a brush for brushing a rail and oiling felt. The provided plane guide rail cleaning device has the functions that cleaning work can be achieved without shutdown, greasy filth and other dirt generated after cleaning cannot influence normal running of surrounding accessories, and on the rail with certain radian, a main spring and an auxiliary spring achieve the automatic compensation function.

Owner:四川星脉电子科技有限责任公司

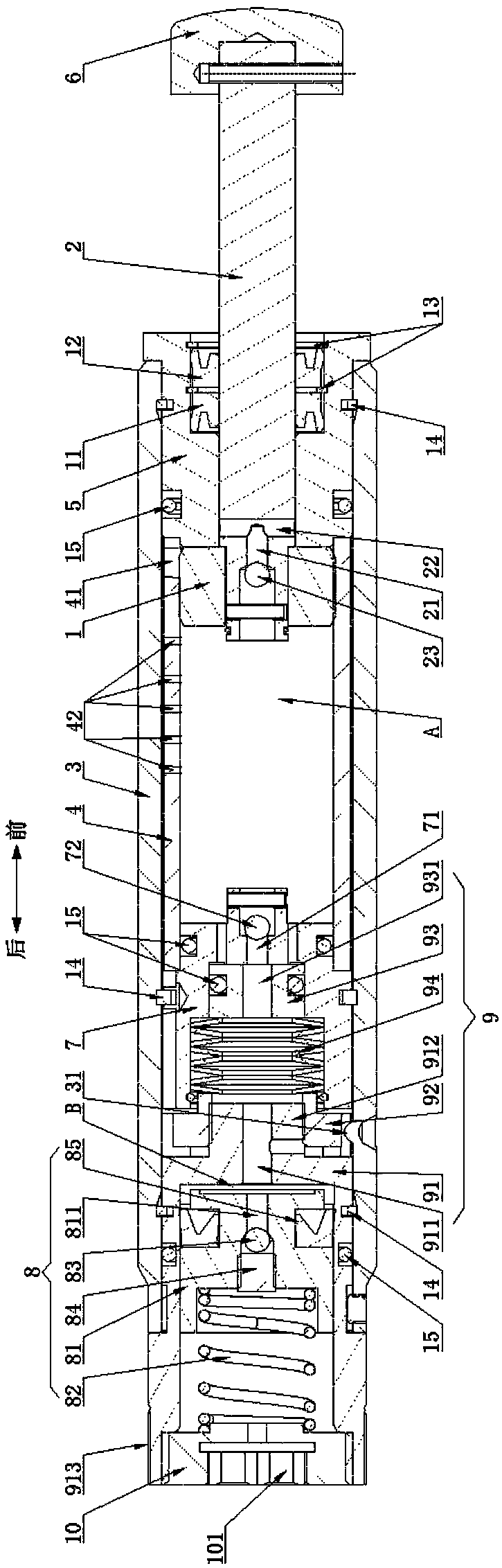

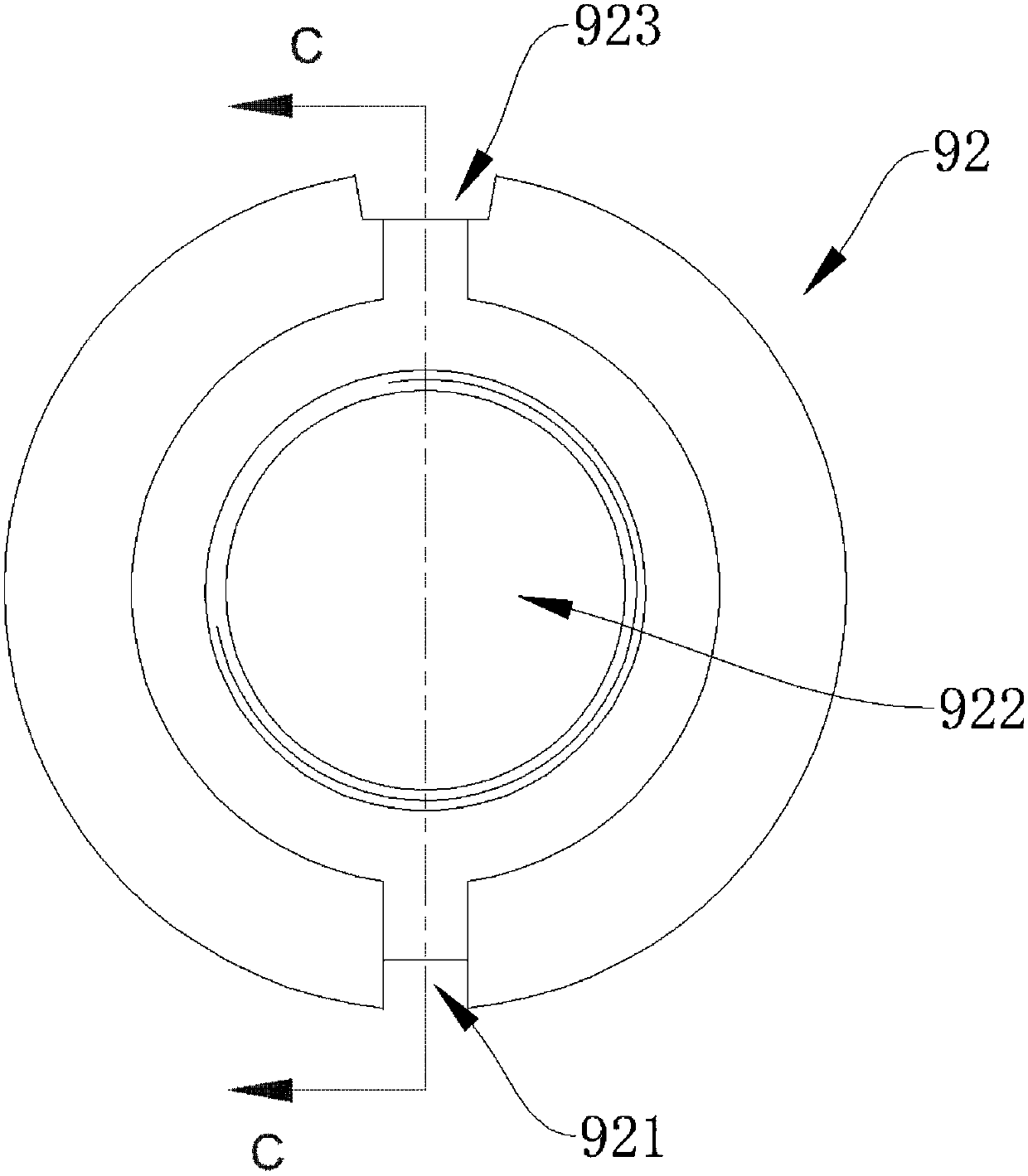

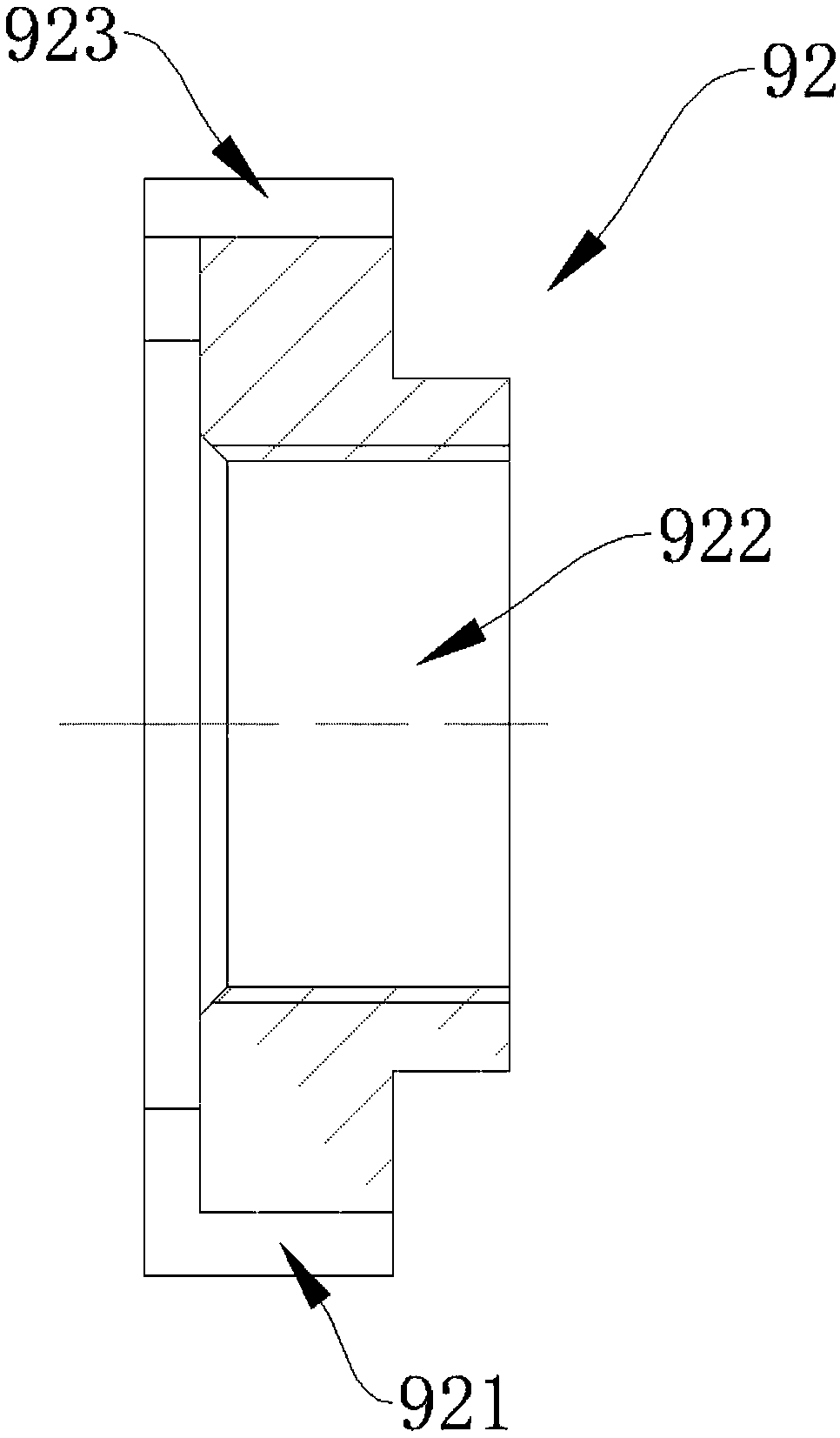

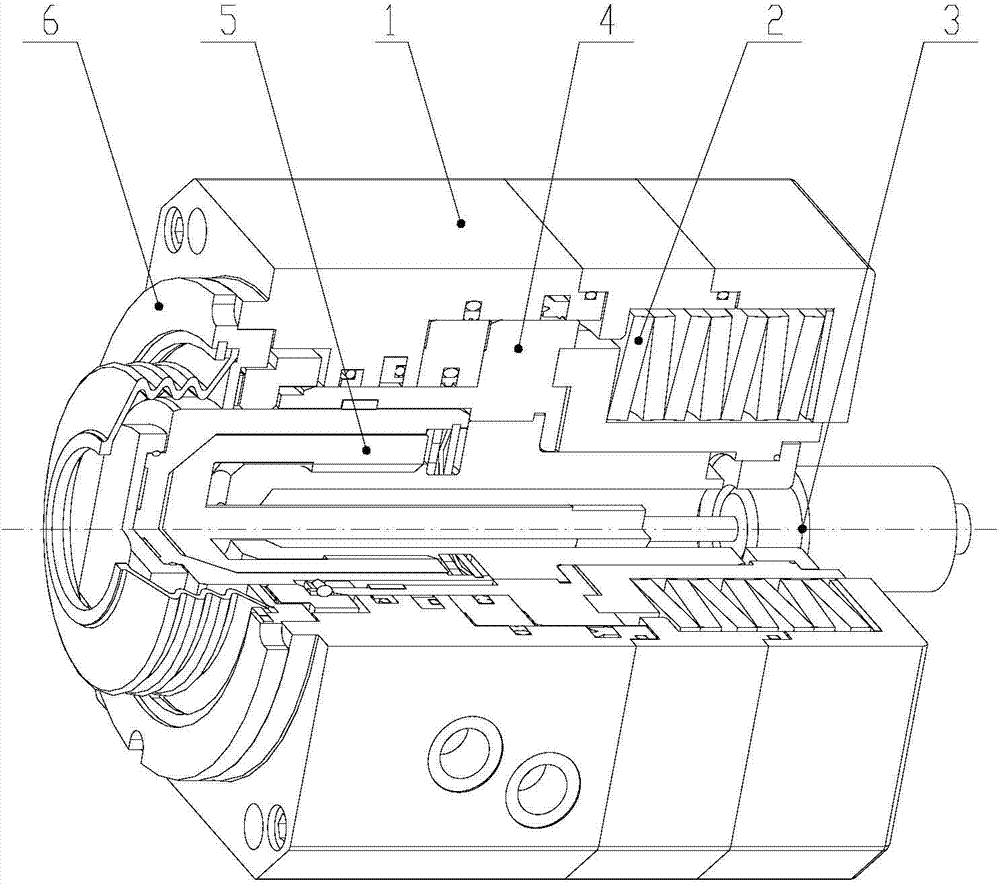

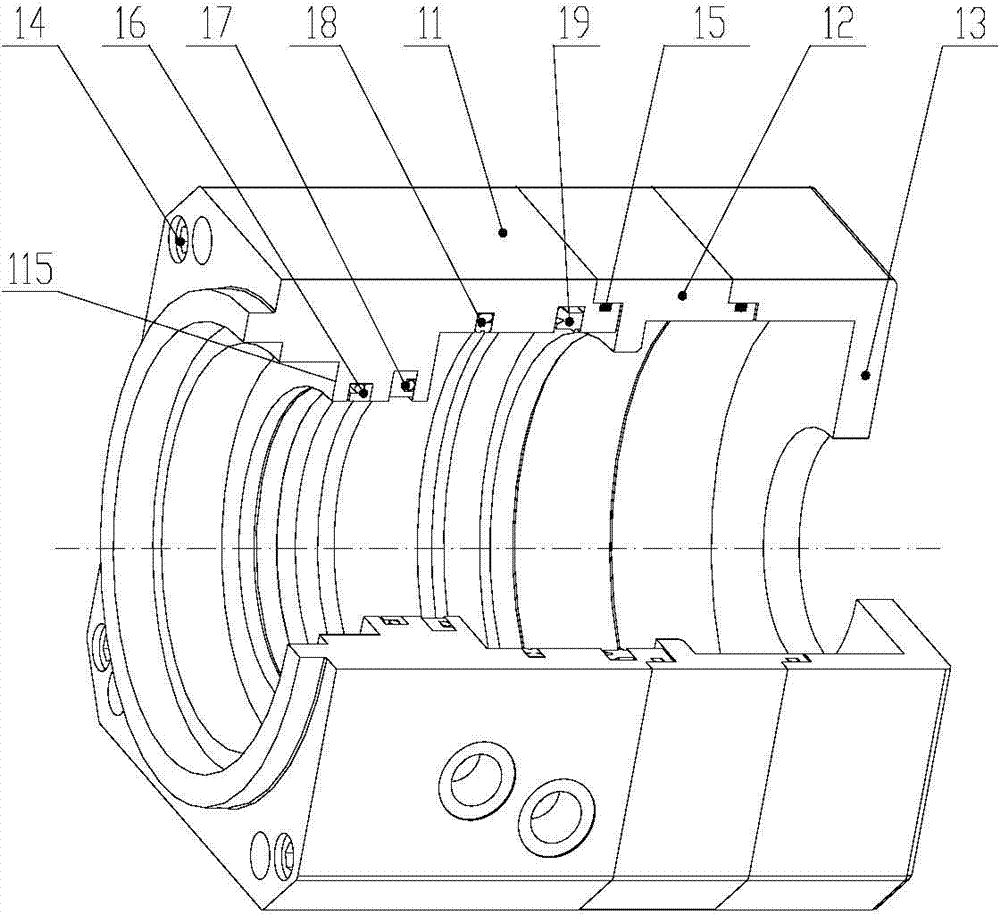

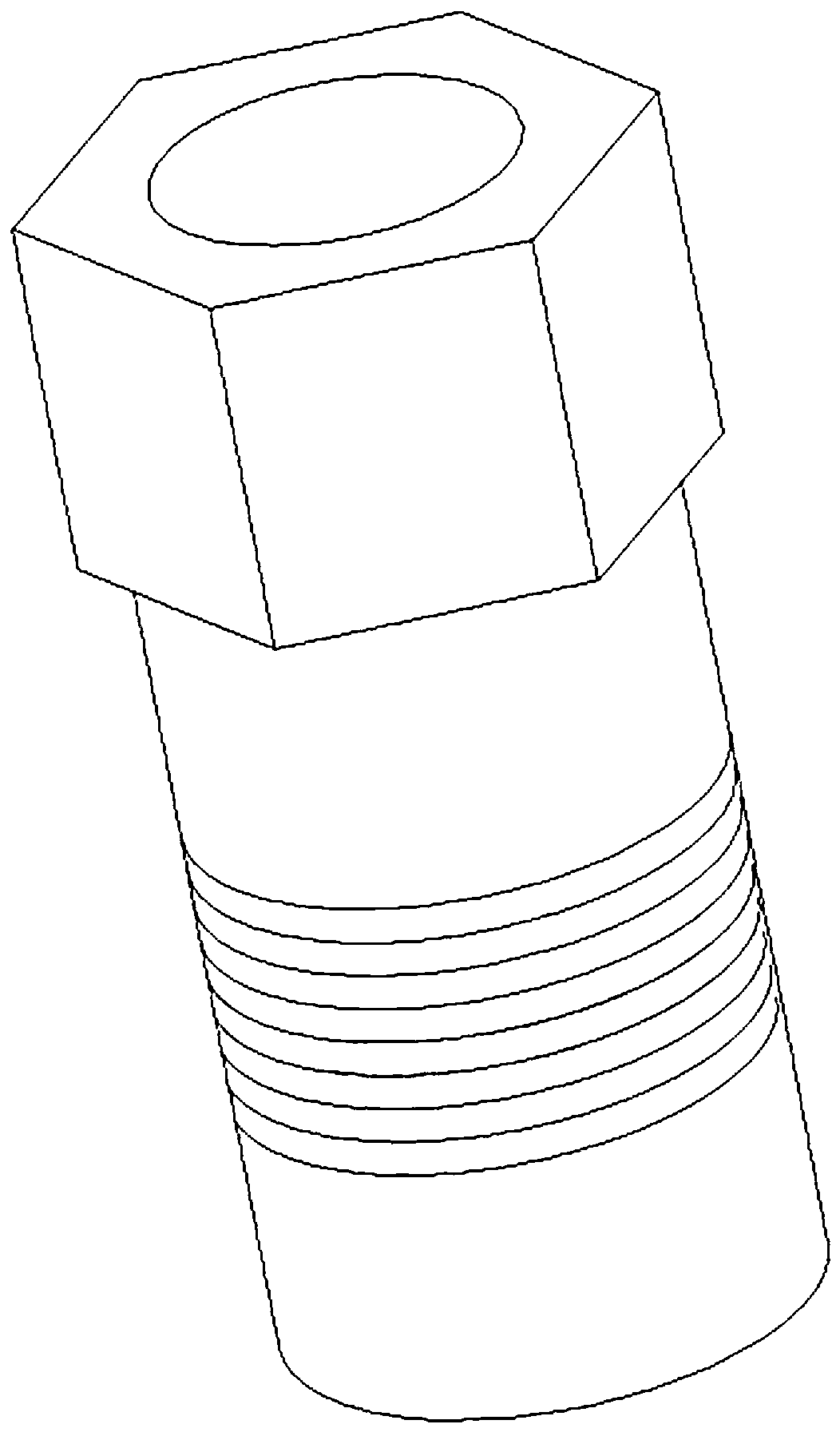

A brake cylinder of a rail vehicle hydraulic brake device

ActiveCN103486171BReal-time monitoring of working statusWith wear monitoring functionBrake actuating mechanismsSlack adjustersControl theoryHydraulic brake

The invention discloses a brake cylinder of a hydraulic brake device of a railway vehicle. The brake cylinder comprises a shell component, a disk spring assembly, an indicator assembly, a piston assembly, a push rod assembly and an end cover assembly. The push rod assembly, the piston assembly, the disk spring assembly and the indicator assembly are sequentially installed in a cylindrical hole inside the shell component from front to back, wherein the cylindrical hole is provided with a step, and the axis of the push rod assembly, the axis of the piston assembly, the axis of the disk spring assembly, and the axis of the indicator assembly are the same as the main axis of the shell component. The end cover assembly is installed on the cylindrical step at the front end of the shell component, and the axis of the end cover assembly is the same as the main axis of the shell component. Brake clearances can be automatically compensated by multiple threads. Compared with an existing brake cylinder, the brake cylinder is simple in structure, convenient to machine and assemble, few in movable parts, and high in reliability, has the friction plate and brake disc abrasion monitoring function and the automatic compensation mechanism running real-time monitoring function, and can remotely monitor the working state of the brake cylinder in real time. Manual brake loosening and adjustment can be achieved on the scene through a manual mechanical brake loosening device, and operation is conveniently and quickly conducted.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

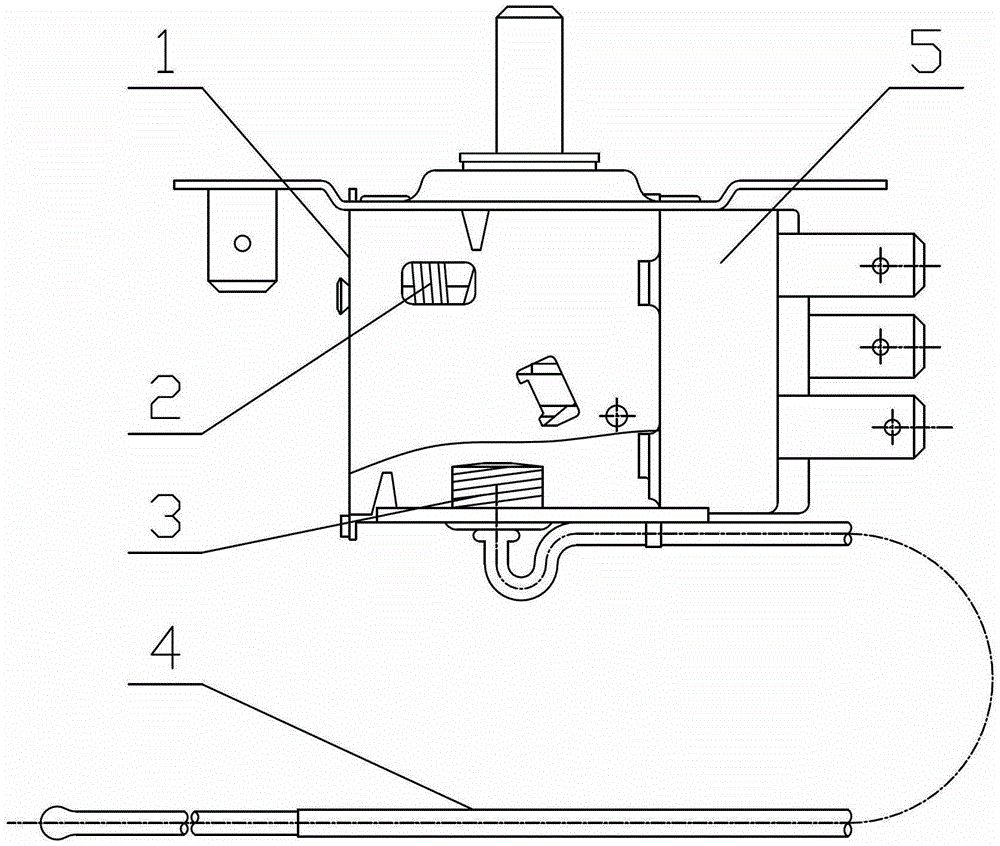

A temperature controller with temperature compensation and temperature compensation method

ActiveCN103234324BEnhance low temperature toleranceSolve the defect that can not start normallyDomestic cooling apparatusLighting and heating apparatusTemperature controlThermostat

The invention discloses a temperature controller with temperature compensation, which comprises a casing, a heating compensating component, a mechanical component arranged inside the casing, and a temperature-sensing component arranged at the bottom of the casing, the temperature-sensing component includes corrugated tube, and a capillary tube connected to the bellows, the heating compensation assembly includes a temperature sensor switch and a heater, the heater is arranged inside the housing and connected to the terminal inside the electrical interface assembly, the The electrical interface assembly is located on the side wall of the housing, the temperature sensor switch is a magnetic switch or a temperature switch, and the heater is a resistance wire or a resistance heating sheet. The invention enhances the low temperature tolerance of the temperature control by adding a heating compensation component inside the temperature controller, and at the same time solves the defect that the existing temperature controller cannot be started normally in a low temperature environment; the heating compensation component is reasonably connected with the electrical interface component , Realize the automatic compensation function of the thermostat temperature.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD

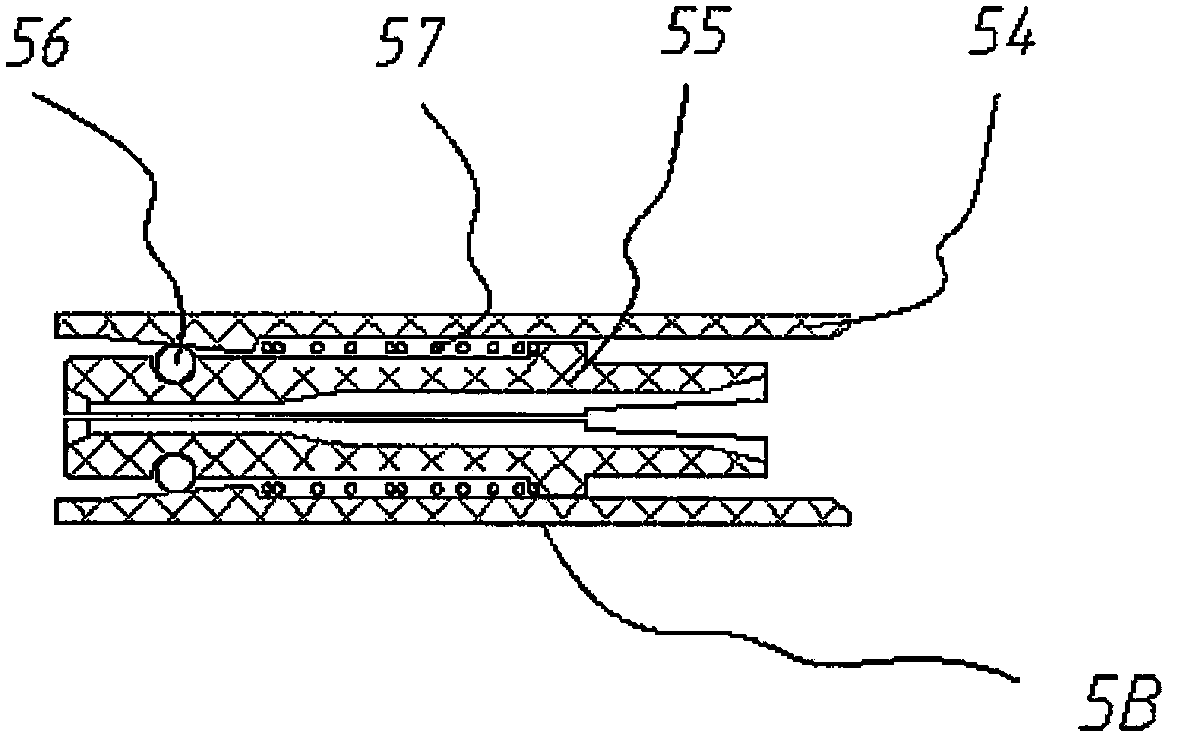

Double-spot double-face floating welding gun

InactiveCN113319492AImprove stress changeImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesLinear motionStructural engineering

The invention provides a double-spot double-face floating welding gun which comprises a first single spot welding mechanism, a second single spot welding mechanism and a linear motion assembly, and the first single spot welding mechanism and the second single spot welding mechanism are installed in a matched mode through the linear motion assembly. The welding gun has the beneficial effects that the two single spot welding mechanisms are connected through the linear motion assembly, two positions can be welded at the same time, the problem that stress changes are generated due to the fact that the two spots are not welded at the same time is solved, the welding precision and the working efficiency are improved, the distance between the two welding positions can be adjusted by adjusting the linear motion assembly, and the welding gun can be suitable for more working scenes.

Owner:天津七所高科技有限公司

Automatic pencil movement and replaceable core automatic pencil

ActiveCN103963513BRealize automatic compensation functionPlay a protective effectPropelling pencilsSteel ballMechanical engineering

The invention provides a fully-automatic mechanical pencil lead and a fully-automatic pencil with the same. The fully-automatic mechanical pencil lead comprises a sharp sleeve part, a body part and a lead storage part, the sharp sleeve part comprises a sharp sleeve, a movable damping part mounted in the sharp sleeve and a damping spring sleeving the movable damping part, and the body part is mounted in the sharp sleeve part and comprises a retainer, a clamping piece arranged in the retainer, a clamping piece spring sleeving the clamping piece and steel balls movably mounted close to the front end of the clamping piece. The lead storage part comprises a lead storage tube and a connecting portion connected with the same, and the connecting portion is connected with the rear end of the sharp sleeve part and matched with the rear end of the body part. One pencil lead penetrates the lead storage tube and the connecting portion, enters the clamping piece and penetrates out of the front end of the movable damping part for writing. The fully-automatic pencil has the advantages that the worn pencil lead can be compensated automatically during writing, and the mechanical leads of the fully-automatic pencil can be replaced mutually.

Owner:SHANGHAI M&G STATIONERY INC

Stem seal automatic monitoring compensation and emergency device

ActiveCN110195799BReal-time feedback of monitoring dataReduce wearSpindle sealingsDetection of fluid at leakage pointHydraulic cylinderRatchet

The invention discloses an automatic monitoring compensation and emergency device for valve rod seal, and relates to the field of valve rod seal. The automatic monitoring compensation and emergency device for valve rod seal sequentially comprises a valve body upper end, a soft filler, a metal ring and a valve rod from bottom to top, wherein a threaded filler compression piece is arranged at the upper end of the metal ring; the valve rod penetrates through the soft filler, the metal ring and the threaded filler compression piece; a mould pressing filler and a sealed O-shaped ring slot are arranged at the top end of the valve body upper end; a medium leakage monitoring ring is arranged at the upper ends of the mould pressing filler and the sealed O-shaped ring; a medium leakage monitoring sensor is arranged on a monitoring port of the medium leakage monitoring ring; the medium leakage monitoring ring is connected with a programmable logic controller; a drive wheel, a rolling steel ball and a driven ratchet wheel are arranged at the upper end of the medium leakage monitoring ring; the drive wheel is connected with a micro hydraulic cylinder; the driven ratchet wheel and the threaded filler compression piece are in clearance fit; and the micro hydraulic cylinder is connected with a micro hydraulic pump and the programmable logic controller. The automatic monitoring compensation andemergency device for valve rod seal can realize the real-time monitoring on the valve rod seal leakage, and has the functions on automatically compensating a soft filler and emergently sealing in case of complete failure.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

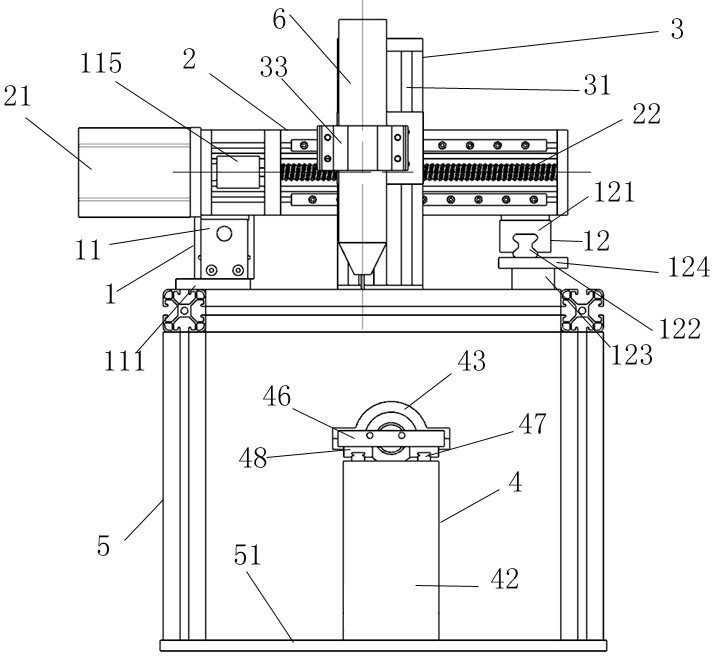

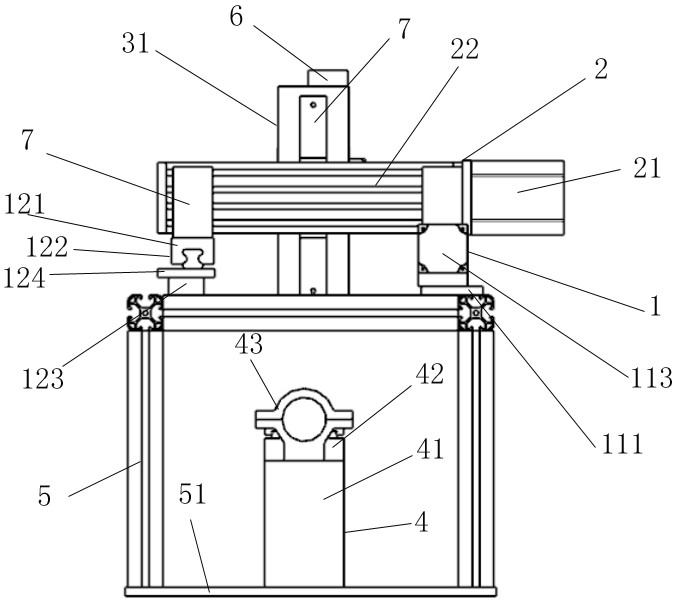

Ultrasonic electric spark deposition equipment capable of automatically compensating electrode loss

PendingCN114703477ARealize automatic compensation functionUniform depositionMetallic material coating processesCross connectionReciprocating motion

The invention discloses an automatic electrode loss compensation ultrasonic electric spark deposition device which comprises an X-axis moving device, a Y-axis moving device, a Z-axis moving device and an ultrasonic auxiliary deposition device, the X-axis moving device is mounted on a base frame, the Y-axis moving device is perpendicularly and crosswise connected with the X-axis moving device, the Z-axis moving device is perpendicularly and crosswise connected with the Y-axis moving device, and the X-axis moving device is mounted on the base frame. The electric spark deposition welding gun is installed on the Z-axis moving device, the Z-axis moving device drives the electric spark deposition welding gun to move up and down, the X-axis moving device and the Y-axis moving device respectively drive the electric spark deposition welding gun to move front and back and left and right, and the ultrasonic auxiliary deposition device is located below the electric spark deposition welding gun. The ultrasonic-assisted deposition device is used for fixing a workpiece and applying vibration to the workpiece. Through multi-direction adjustment, the reciprocating motion of the air cylinder and the thrust of the sliding block are converted into continuous downward pressure of the electrode, and it is guaranteed that the discharge gap between the electrode and a workpiece is at a stable value under the condition that the electrode is continuously lost.

Owner:ZHEJIANG UNIV OF TECH

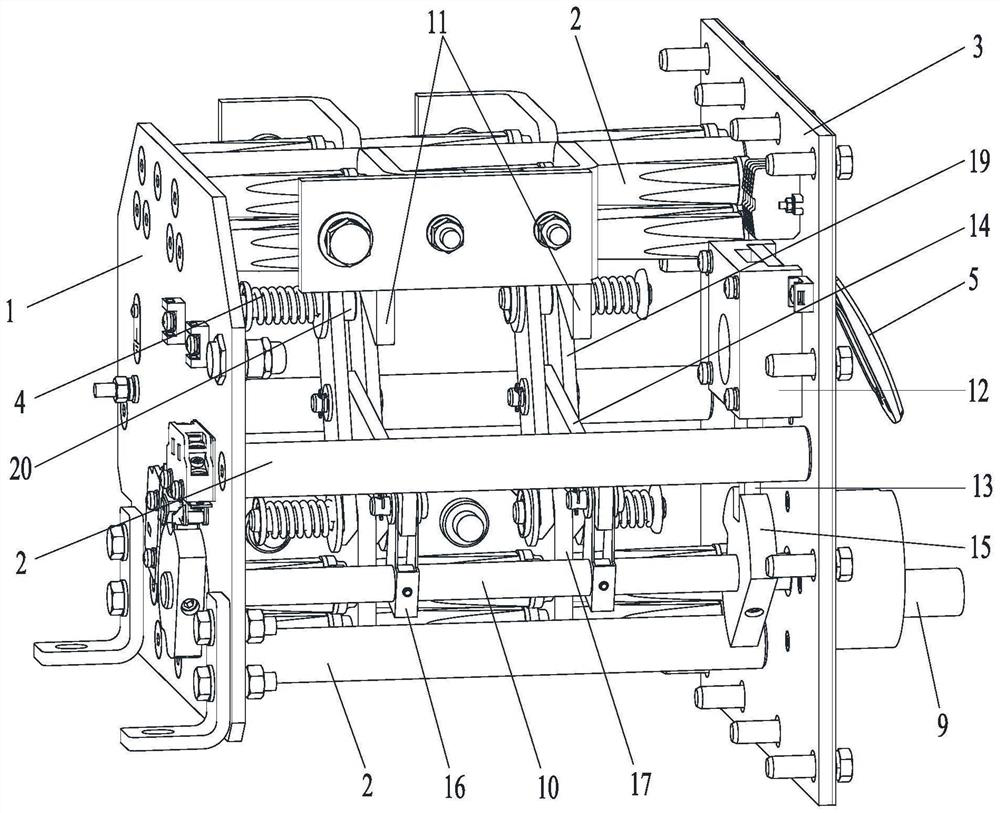

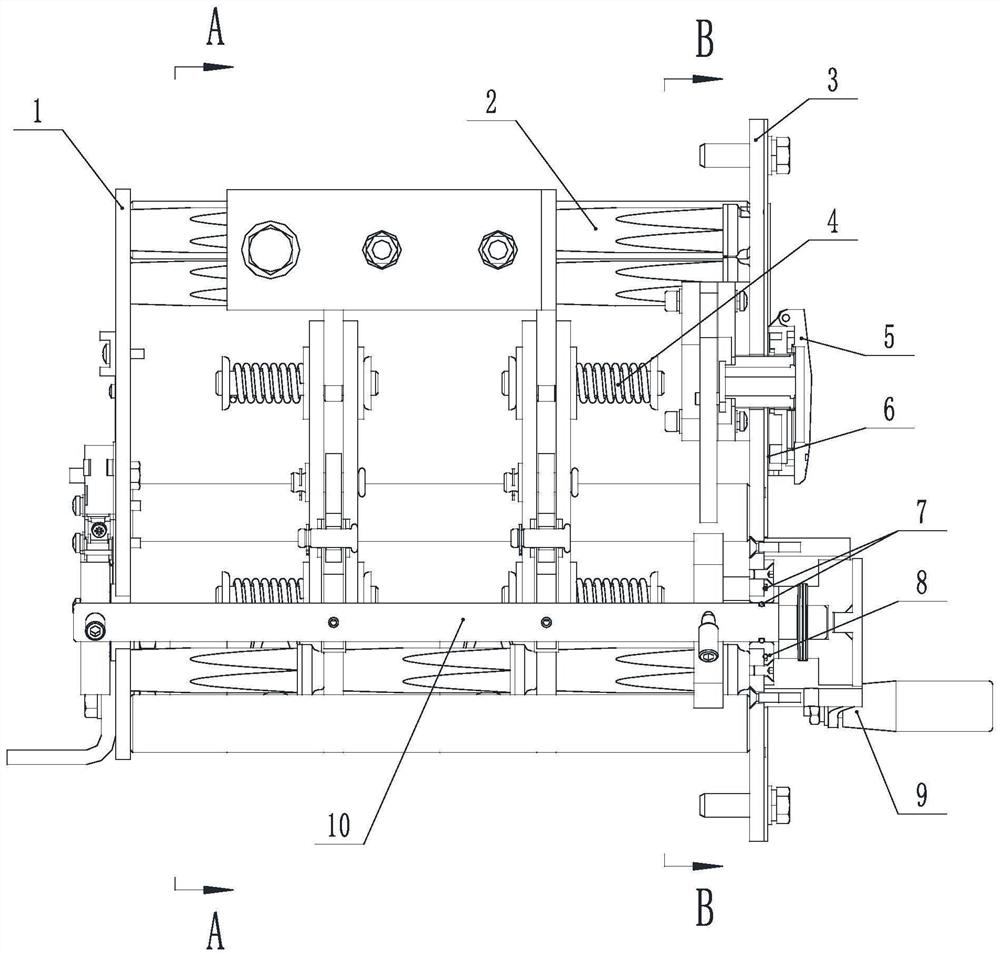

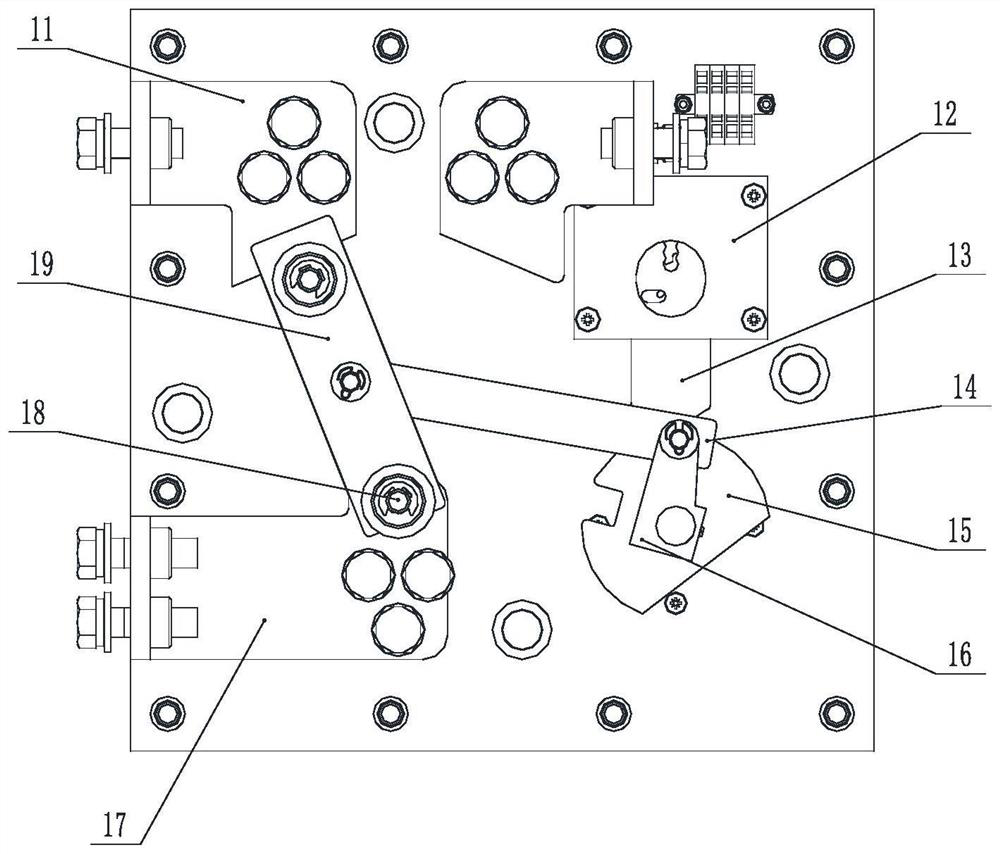

High-protection interlocking self-compensation isolating switch

PendingCN114664593AEnsure safetyRealize automatic compensation functionContact operating partsAir-break switch detailsStructural engineeringContact position

The invention discloses a high-protection type interlocking self-compensation disconnecting switch which comprises a front panel and a rear panel. A moving contact and two static contacts are arranged between the front panel and the rear panel, and the distance between the moving contact and the front panel or the distance between the static contacts and the rear panel are consistent. The moving contact is hinged with one end of the moving plate, the other end of the moving plate can be shifted between the two static contacts, hinged shafts or fixed shafts are arranged at two ends of the moving plate, compression springs are arranged on the hinged shafts or the fixed shafts, spacer bushes are arranged between the fixed shafts and the moving plate, and the thickness of the spacer bushes is smaller than that of the static contacts; the movable plate is in transmission with the main rotating shaft through a connecting assembly. The hinge shaft is hinged to the movable plate and the movable contact, the compression spring is arranged, rotation flexibility and compression reliability are guaranteed, the compression spring is arranged at the contact position of the movable plate and the static contact, the automatic compensation function of the contact position of the movable contact and the static contact is achieved, and therefore the movable contact and the static contact can be in good contact, and the service life of the movable contact and the static contact is prolonged. And the safety of the power supply circuit and power supply equipment is ensured.

Owner:XIANYANG YAHUA ELECTRONIC APPLIANCE CO LTD

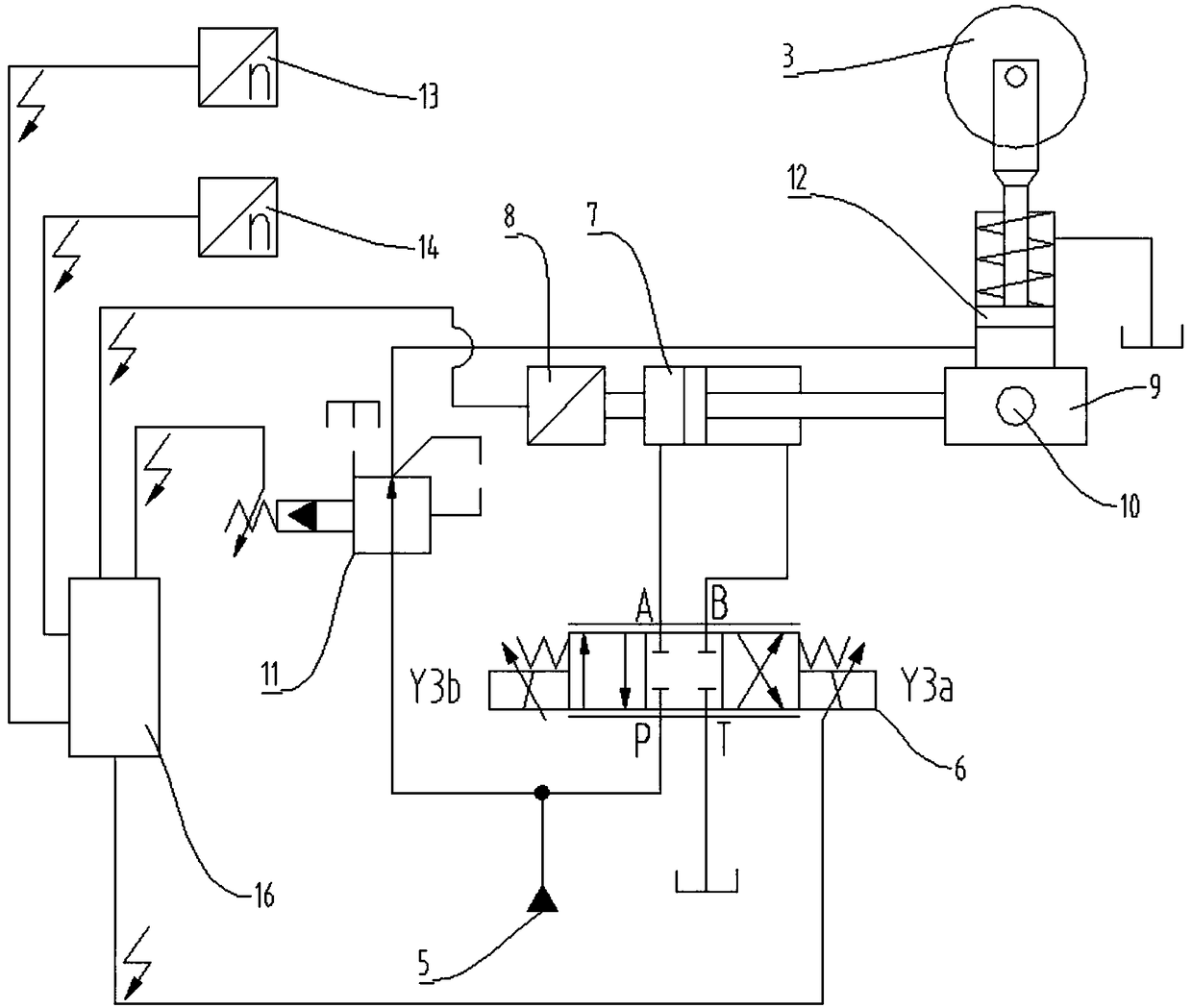

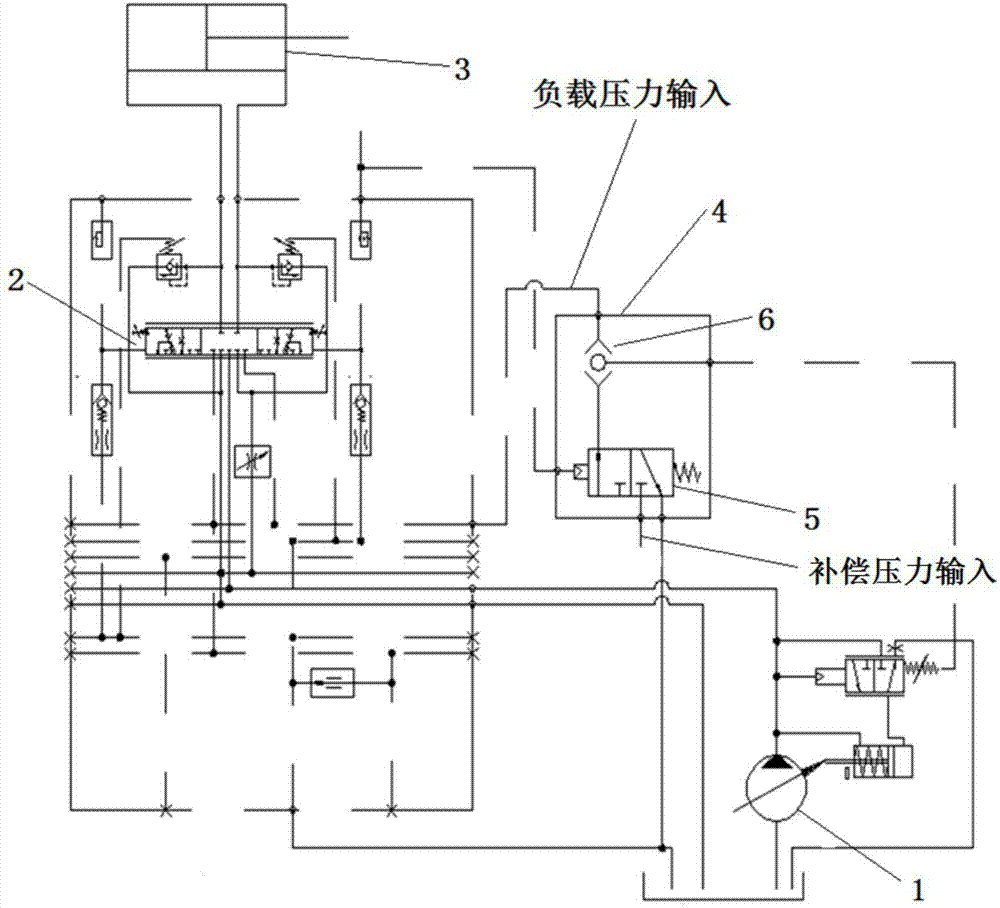

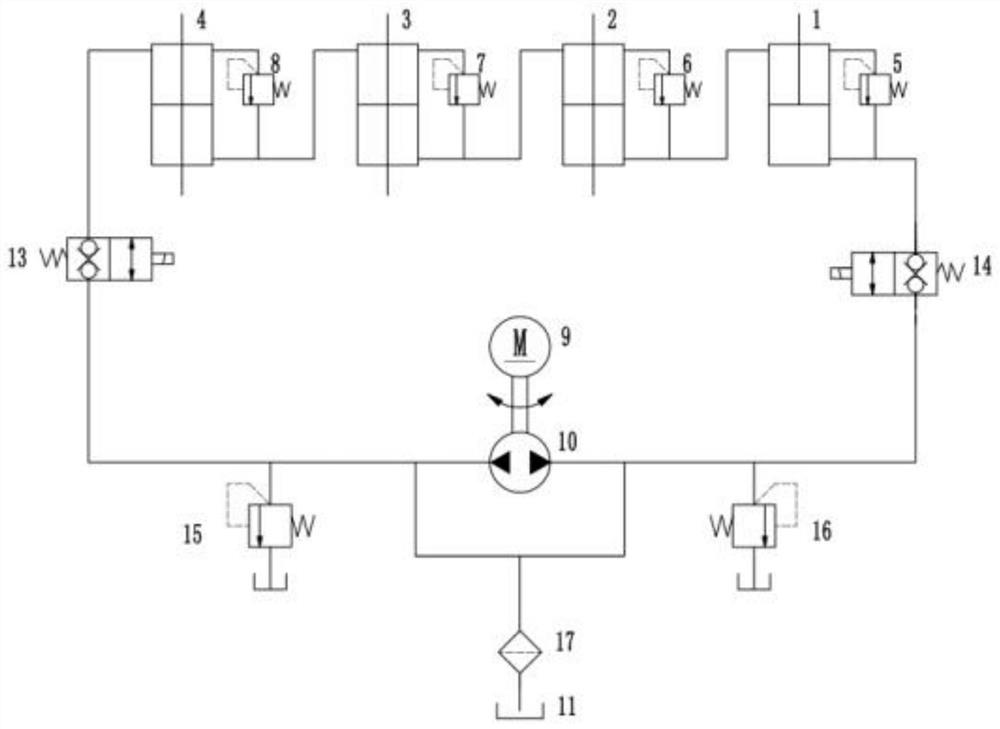

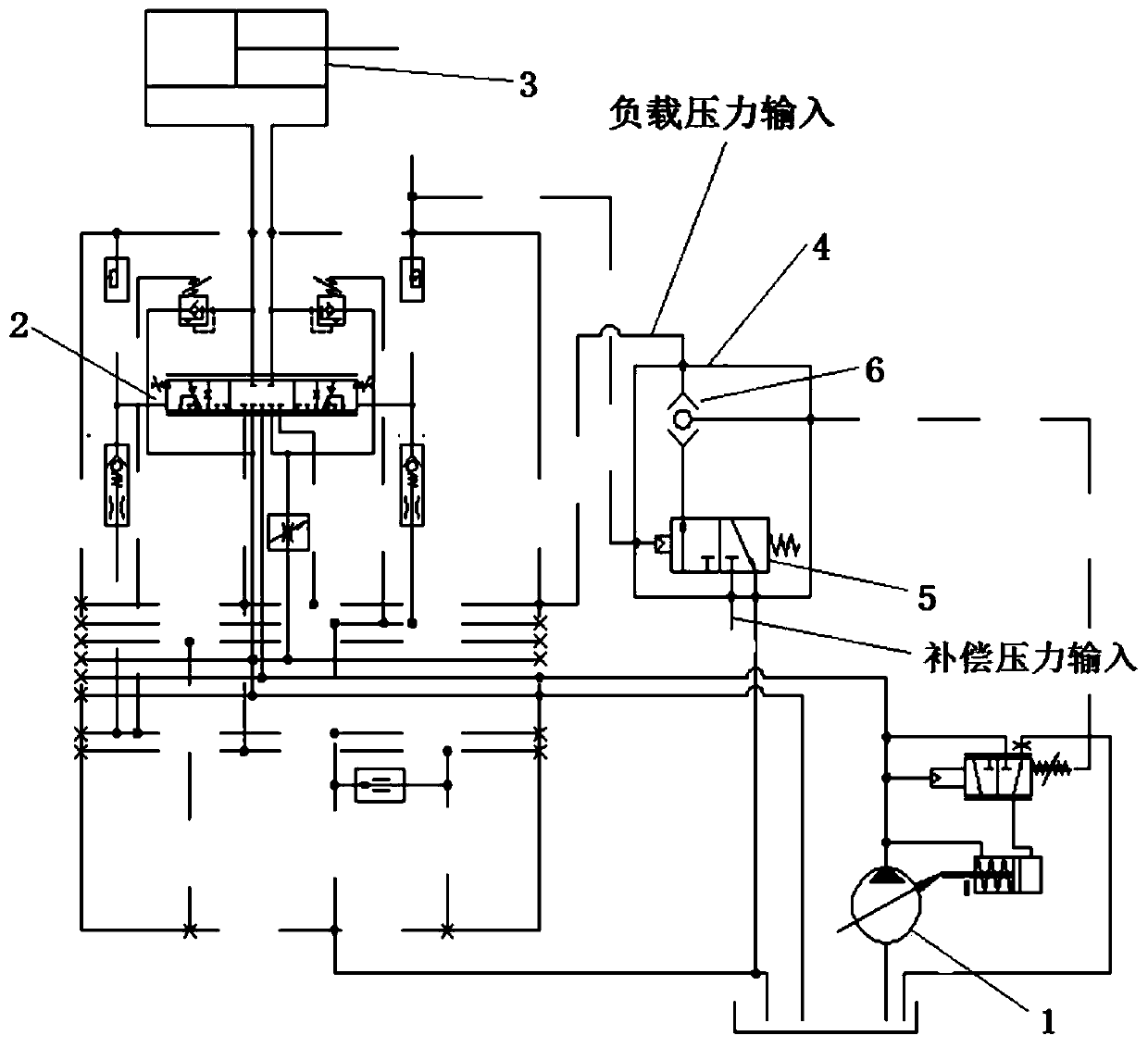

Hydraulic system with flow compensation function and engineering machinery

ActiveCN107477039AWith automatic compensation functionWith automatic adjustmentServomotor componentsServomotorsLoad sensingControl valves

The invention relates to a hydraulic system with a flow compensation function and engineering machinery provided with same. The hydraulic system comprises a main pump which is connected with an oil tank and controlled in a load sensing mode, actuating mechanism, a main control valve which is connected with the main pump and the actuating mechanism and used for distributing hydraulic oil for the actuating mechanism, a pilot pressure input part which is connected with the main control valve so as to input pilot pressure to the main control valve, and a flow compensation mechanism, wherein the flow compensation mechanism comprises a compensation pressure input part and a flow compensation valve block; the compensation pressure input part is used for inputting constant compensation pressure to the flow compensation valve block; and the flow compensation valve block is connected with the pilot pressure input part, the compensation pressure input part, a load pressure output pipeline of the main control valve and a displacement adjusting mechanism of the main pump and used for receiving the compensation pressure and the load pressure under the condition that the pilot pressure input part inputs the pilot pressure and inputting the higher one of the compensation pressure and the load pressure to the main pump so as to control the displacement of the main pump.

Owner:WEICHAI POWER CO LTD +1

Automatic detecting and compensating circuit for single and double lamps

ActiveCN1822744BRealize automatic compensation functionElectrical apparatusElectric lighting sourcesElectrical ballastControl signal

Owner:DONGYANG TOSPO LIGHTING

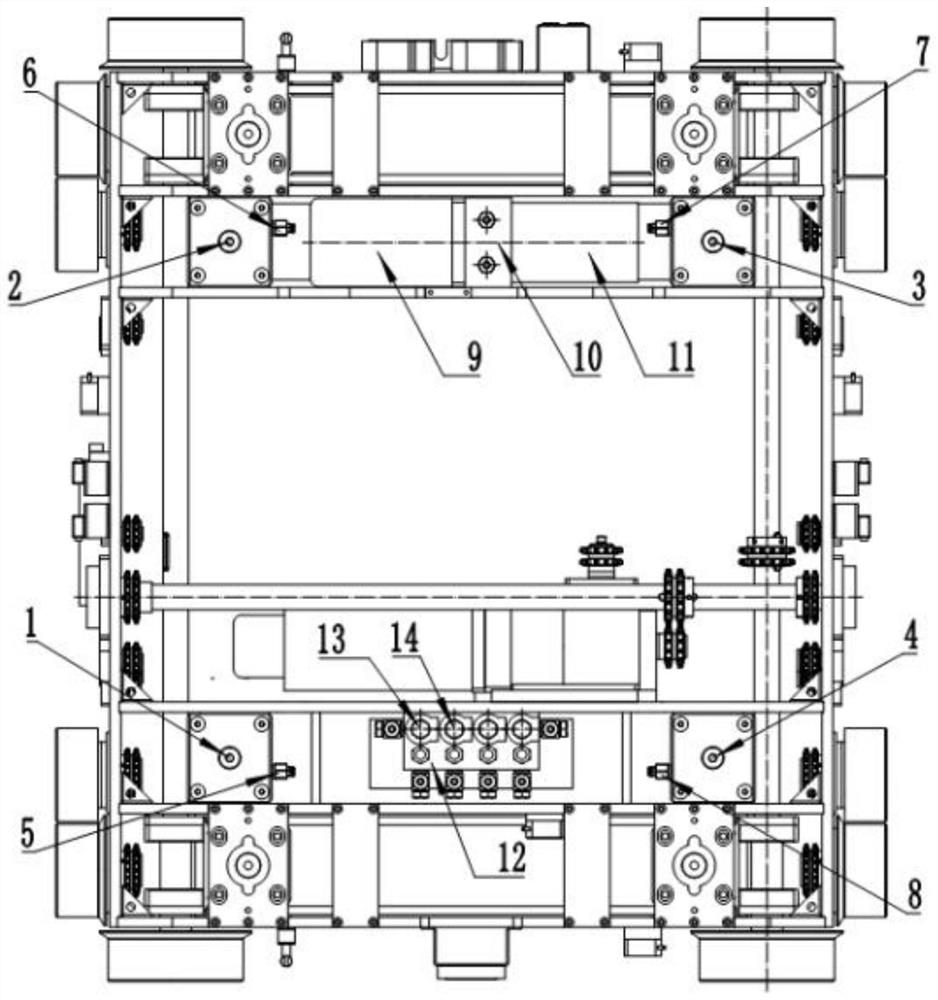

Synchronous lifting mechanism and four-way shuttle vehicle

InactiveCN113353835ASolve the technical problem of reduced synchronization accuracyImprove stabilityLifting devicesFluid-pressure actuator componentsControl engineeringExecution unit

The invention is applicable in the technical field of four-way shuttle vehicles, and provides a synchronous lifting mechanism. The synchronous lifting mechanism comprises a power unit, an execution unit and a control unit; the power unit is used for driving hydraulic oil to move; the execution unit comprises a plurality of oil cylinders which are arranged in series, an oil inlet of each oil cylinder is provided with an overflow piece, the overflow pieces and the oil cylinders are installed in parallel, and the overflow pieces are used for supplementing the oil cylinders with oil in return strokes of the oil cylinders and forcibly resetting piston rods of the oil cylinders; and the control unit is used for controlling the power unit and the execution unit. The synchronous lifting mechanism has the beneficial effects that an automatic compensation function is realized by the aid of internal parallel oil paths of overflow valves and the oil cylinders, the technical problem that the synchronization precision of the lifting mechanism is reduced due to internal leakage and external leakage of a hydraulic system is solved, the stability of the four-way shuttle vehicle during working is improved, and the later maintenance cost and workload are reduced.

Owner:江苏智库智能科技有限公司

Self-compensating servo wiring device for water tank type wire drawing machine

ActiveCN102172669BWith disconnection alarm functionAvoid the phenomenon of "rising wheel"Metal working apparatusBall screwElectric machinery

The invention discloses a self-compensating servo wiring device for a water tank type wire drawing machine, which comprises a tension testing unit, a wire distributing device and a wire collecting device, wherein the tension testing unit consists a first wire roller, a second wire roller, a tensioning wire roller, an angular displacement sensor, a tension rod and a guide groove; the wire distributing device consists a third wire roller, a synchronous belt, a fourth wire guide roller, a screw nut, a ball screw, a coupler, a wiring servo motor, a fifth wire roller, a wiring base and an end cover; and the wire collecting device consists of a spool and a wire collecting servo motor. The device adopts the tensioning wire roller for testing the tension of a metal wire, has a simple structure and has a metal wire breakage alarming function for giving an alarm in time incase of breakage of the metal wire.

Owner:JIANGSU HENGLI MACHINE TOOL

Control method of milling cutter type board dividing machine system

PendingCN112867252AReduce programming and debugging timeEliminate product scrapInsulating layers/substrates workingManufacturing engineeringMilling cutter

The invention discloses a control method of a milling cutter type board dividing machine system. The control method comprises the following eight basic operation steps of product placing, image collecting, precise positioning, cutting point selecting, cutting track adding, program storing, track modifying and cutting completing. The control method of the milling cutter type board dividing machine system is as follows. On one hand, when the cutter is worn, the distance of each sinking section can be set to realize the automatic sinking function of the cutter, and meanwhile, when the cutter is broken off abnormally in the use process, the machine performs monitoring through the cutter breaking and height detection sensor and immediately feeds back a signal to the PC terminal, and the PC terminal sends an instruction to stop working, an alarm prompt is made in software for displaying, so that an operator is reminded of checking and replacing, what is ensured is that the descending position of the cutter on the z-axis is consistent after the cutter is replaced every time and the cutter slides down for a small distance, and a PCB and elements at the bottom of a product are prevented from being damaged by cutting.

Owner:广东千博瑞智能科技有限公司

Hydraulic system and engineering machinery with flow compensation function

ActiveCN107477039BWith automatic compensation functionWith automatic adjustmentServomotor componentsServomotorsLoad sensingControl valves

The invention relates to a hydraulic system with a flow compensation function and engineering machinery provided with same. The hydraulic system comprises a main pump which is connected with an oil tank and controlled in a load sensing mode, actuating mechanism, a main control valve which is connected with the main pump and the actuating mechanism and used for distributing hydraulic oil for the actuating mechanism, a pilot pressure input part which is connected with the main control valve so as to input pilot pressure to the main control valve, and a flow compensation mechanism, wherein the flow compensation mechanism comprises a compensation pressure input part and a flow compensation valve block; the compensation pressure input part is used for inputting constant compensation pressure to the flow compensation valve block; and the flow compensation valve block is connected with the pilot pressure input part, the compensation pressure input part, a load pressure output pipeline of the main control valve and a displacement adjusting mechanism of the main pump and used for receiving the compensation pressure and the load pressure under the condition that the pilot pressure input part inputs the pilot pressure and inputting the higher one of the compensation pressure and the load pressure to the main pump so as to control the displacement of the main pump.

Owner:WEICHAI POWER CO LTD +1

Small-sized pressurizing device

InactiveCN105841939ARealize automatic compensation functionEasy to carryMachine part testingMaterial strength using tensile/compressive forcesWater circulationEngineering

The invention relates to a small-sized pressurizing device, which is used for testing a small-caliber valve. The small-sized pressurizing device comprises a clamping device, which is used for clamping a valve; a water circulation system, which is communicated with the clamping device; a pneumatic pressurizing device, which is connected with the water circulation system, and is used for pressure control of a water circulation system. By adopting the pushing of the supercharging cylinder, a plurality of kilograms of the air pressure can be converted into the highest 10MPa of the pressure, and at the same time, the automatic compensation function of the pressure loss can be realized. The small-sized pressurizing device is advantageous in that the carrying is convenient, the structure is simple, the maintenance is convenient, the use is practical and reliable; the water in the water tank can be recycled, and the use is environmental friendly and energy-saving.

Owner:WUZHONG INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com