Automatic detecting and compensating circuit for single and double lamps

A detection circuit and automatic detection technology, applied in the direction of electric light sources, electrical components, lighting devices, etc., can solve problems such as differences, incompatible sensitivity of protection signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

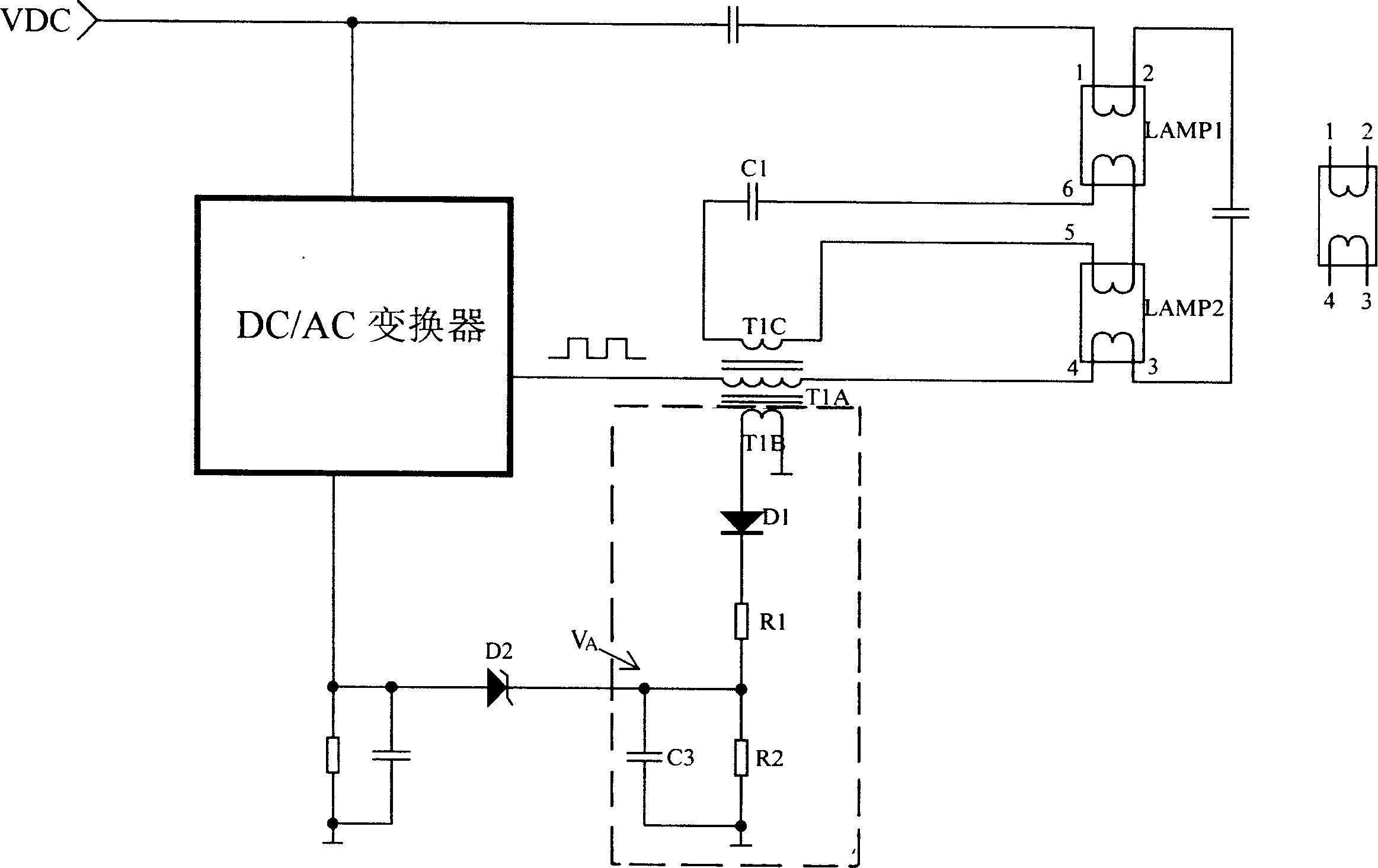

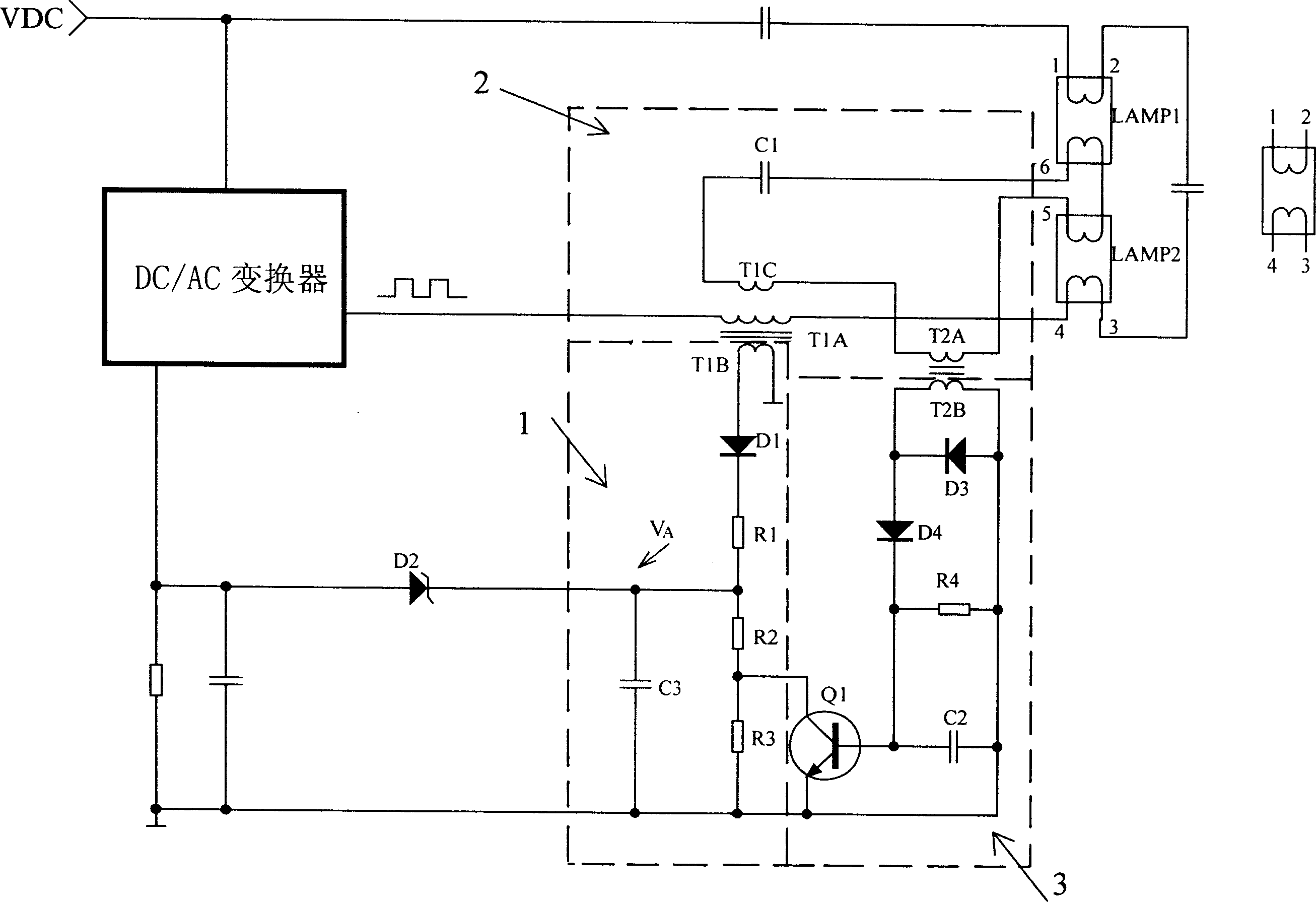

Embodiment 1

[0017] see figure 2 , outside the virtual frame is a typical electronic ballast circuit, including DC / AC converter (including abnormal protection execution circuit), output circuit and fluorescent tube circuit, between the DC / AC converter, output circuit and fluorescent tube circuit , increasing the single and double lamp automatic detection compensation circuit of the present invention (the circuit in the dashed frame). The single and double lamp automatic detection compensation circuit is composed of abnormal signal detection circuit 1, single and double lamp detection circuit 2 and single and double lamp control circuit 3, and its abnormal protection signal is taken from the secondary winding T of the output inductor 1B , and its specific circuit structure is: an output inductor and three windings T 1A , T 1B , T 1C , three rectifier diodes D 1 、D 3 、D 4 , a current limiting resistor R 1 , two compensating resistors R 2 , R 3 , a current sensor T 2 Two windings T...

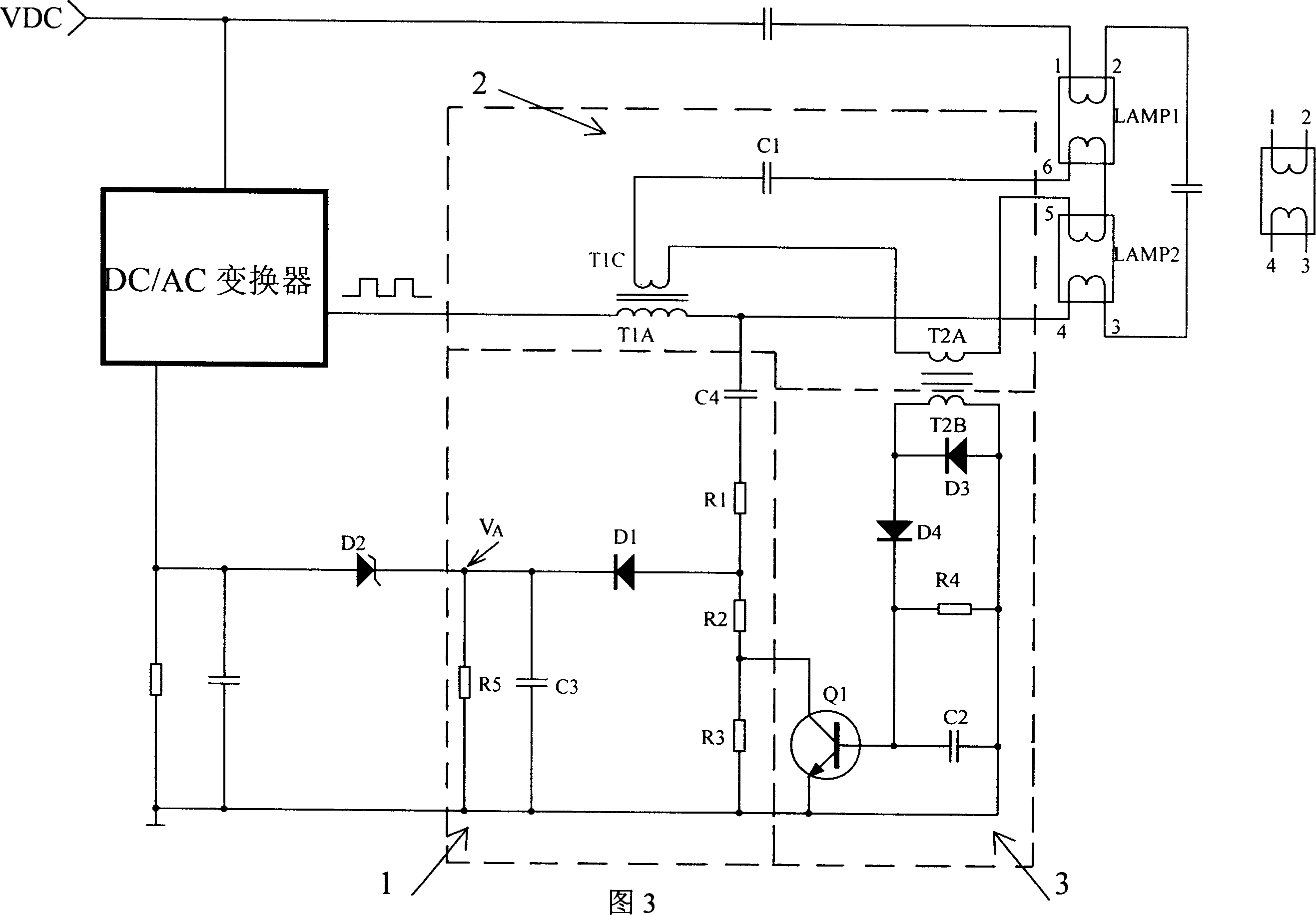

Embodiment 2

[0020] Referring to Fig. 3, the electronic ballast circuit of this embodiment is the same as the previous embodiment, and the single and double lamp automatic detection compensation circuit of the present invention is inside the virtual frame; the single and double lamp automatic detection compensation circuit is also composed of the abnormal signal detection circuit 1 , single and double lamp detection circuit 2 and single and double lamp control circuit 3, the abnormal protection signal is taken from the main winding T of the output inductor 1A The common end of the terminal and the 4 pins of the fluorescent lamp circuit is composed of: an output inductor and two windings T 1A , T 1C , three rectifier diodes D 1 、D 3 、D 4 , a current limiting resistor R 1 , two compensating resistors R 2 , R 3 , a current transformer T 2 Two windings T 2A , T 2B , a control transistor Q 1 , a filter resistor R 4 and a filter capacitor C 2 , a filament current limiting capacitor C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com