Ultrasonic electric spark deposition equipment capable of automatically compensating electrode loss

A kind of spark deposition equipment, electric spark deposition technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of unstable discharge, low deposition efficiency, and no longer obvious advantages, so as to improve the surface performance of the coating and reduce the Effect of Surface Roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to this.

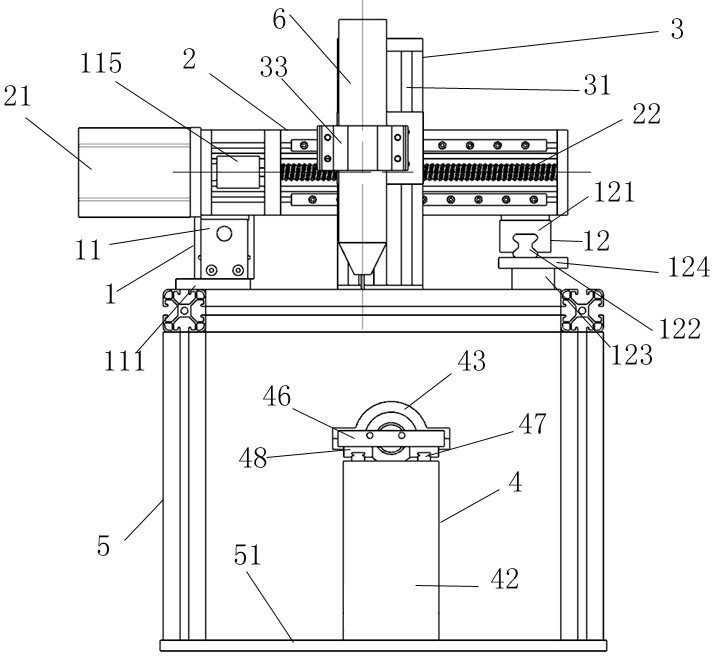

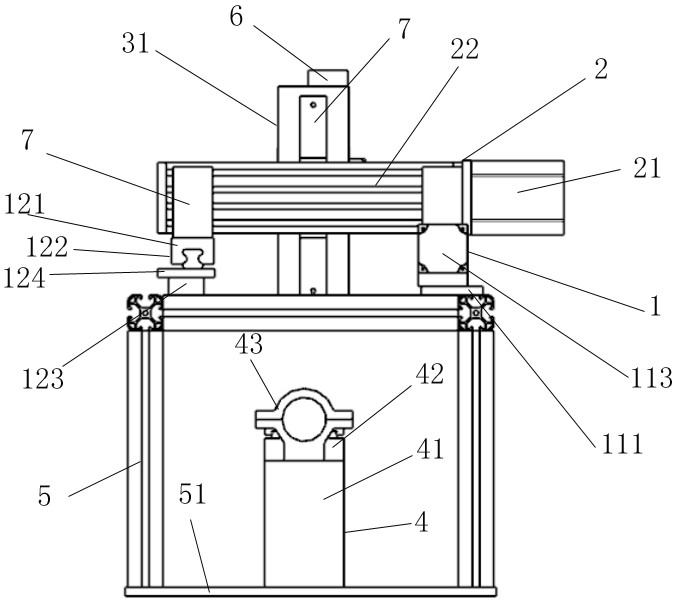

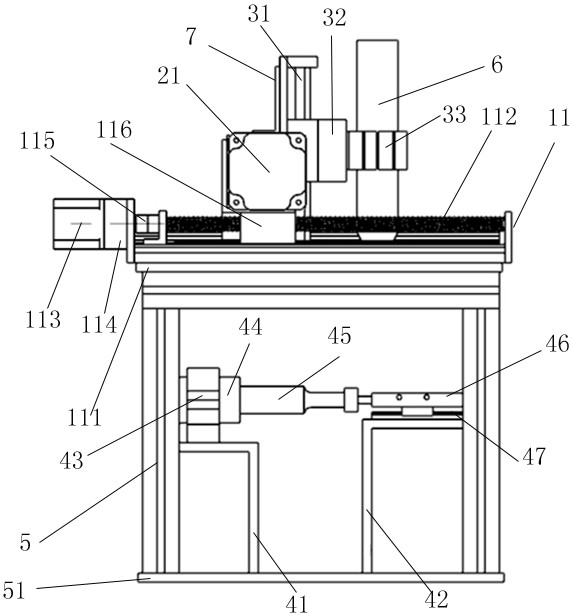

[0032] like Figure 1 to Figure 7 As shown, an ultrasonic EDM device with automatic compensation of electrode loss includes an X-axis moving device 1, a Y-axis moving device 2, a Z-axis moving device 3, an ultrasonic-assisted deposition device 4, a base frame 5 and an EDM torch 6 , the X-axis moving device 1 includes a first moving device 11 and a second moving device 12, the first moving device 11 and the second moving device 12 are arranged in parallel on the upper sides of the base frame 5, and the first moving device 11 includes a first connection The plate 111, the first ball screw 112, the first step motor 113, the reducer 114, the coupling 115 and the first slider 116, the first connecting plate 111 is horizontally installed on the base frame 5, the first ball screw The bottom surface of 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com