Friction transmission stepless speed change device

A continuously variable transmission device and friction transmission technology, applied in the field of transmission, can solve the problems of metal belts being easily damaged, limited in strength, unable to bear large loads, etc., and achieve the effect of precise control process and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

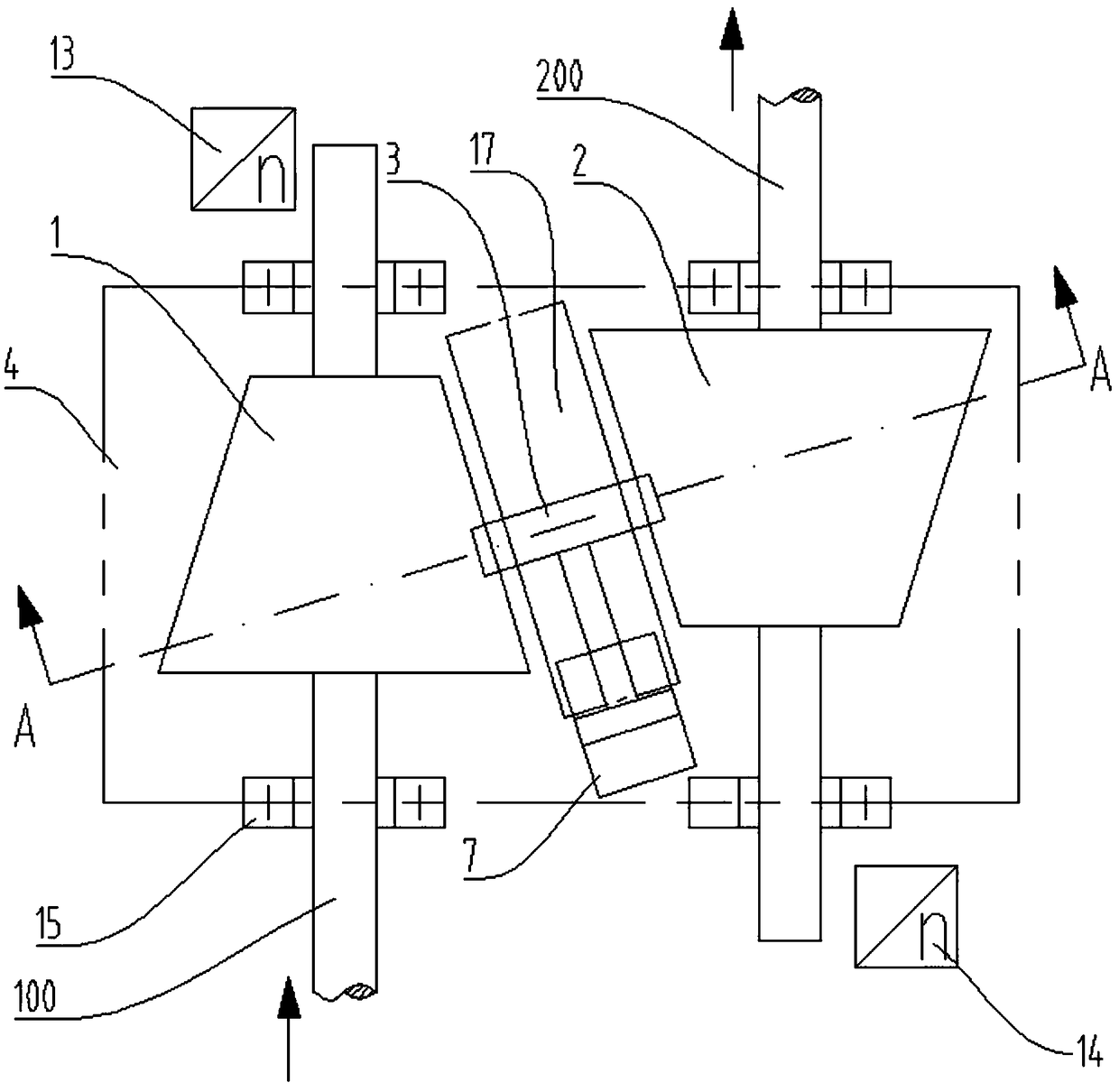

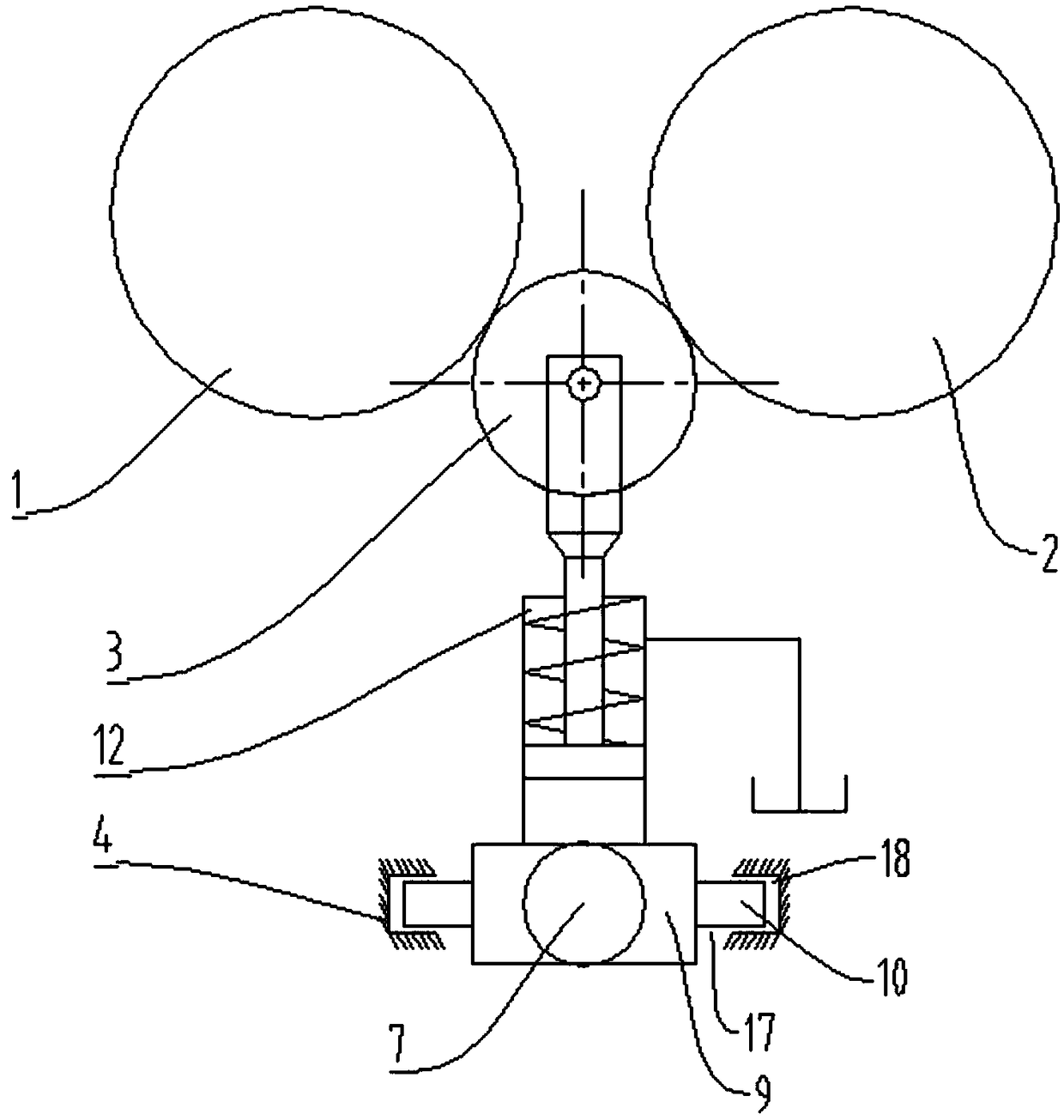

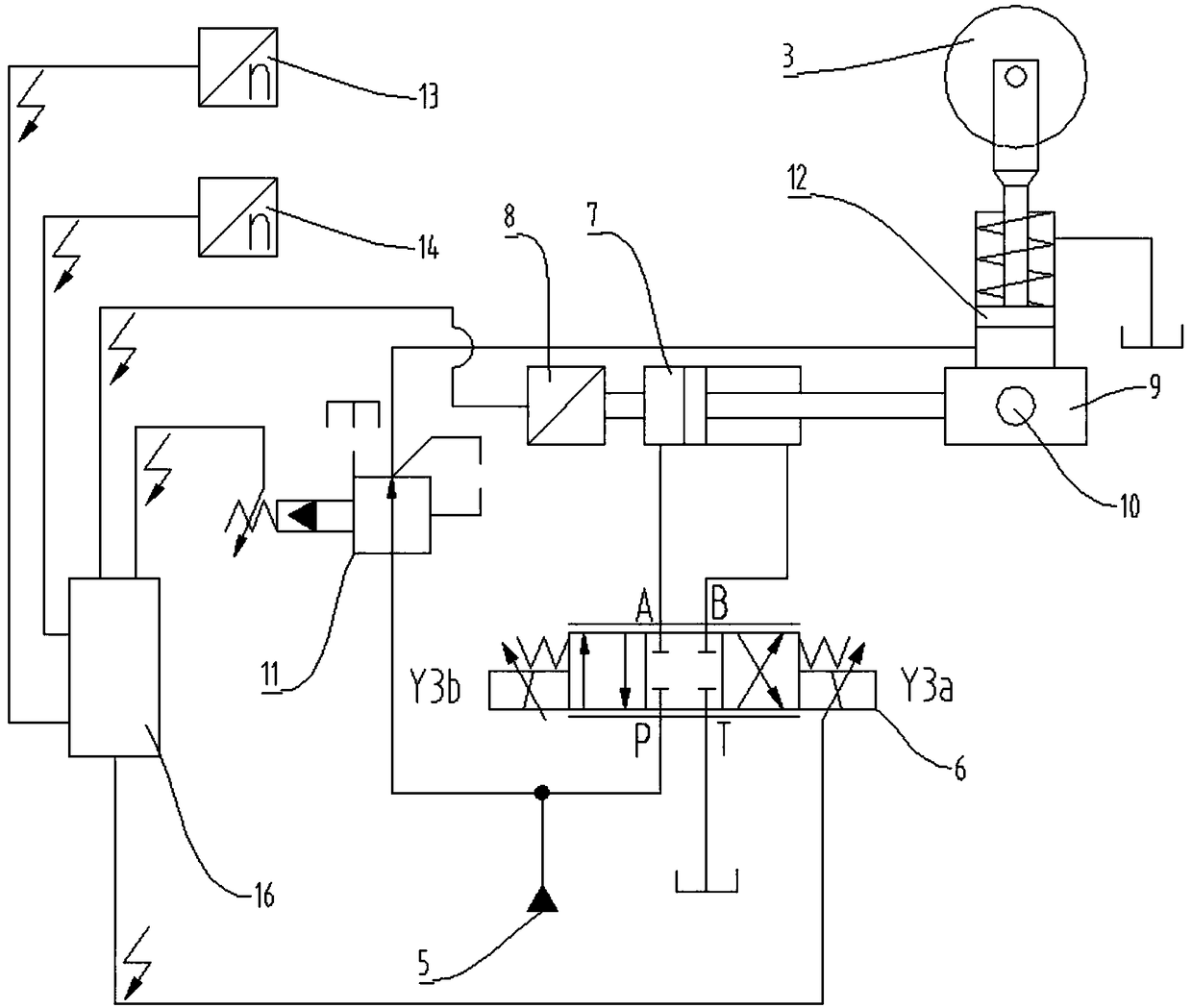

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] like Figure 1 to Figure 3 As shown, a frictionally driven continuously variable transmission device includes a casing 4, a driving shaft 100, a driven shaft 200, an intermediate wheel 3 arranged inside the casing 4, a second hydraulic cylinder 12 and a first hydraulic cylinder 7; The casing 4 is a box-type structure, which provides the installation basis for all components, and can also act as an oil tank for the hydraulic system. When the oil tank is full, an oil collecting cavity can be reserved at the bottom of the casing 4; the driving shaft 100 It is arranged in parallel with the driven shaft 200 and is respectively rotatably assembled on the left and right sides of the interior of the housing 4; the interior of the housing 4 is provided with mutually oppositely arranged and fixedly sleeved on the driving shaft 100 and the driven shaft 200 respectively. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com