Production method of high-hardness low-carbon low-alloy steel plate

An alloy steel plate and a production method technology, applied in the metallurgical field, can solve the problems of low life of the steel plate, deformation of the surface of the drum, etc., and achieve the effect of reducing the cost of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

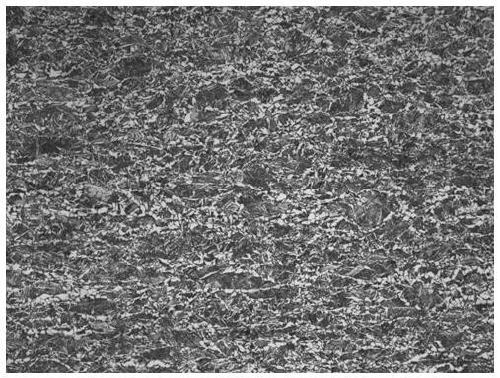

Image

Examples

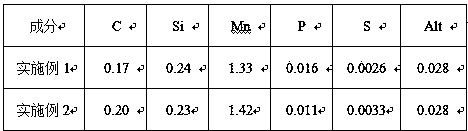

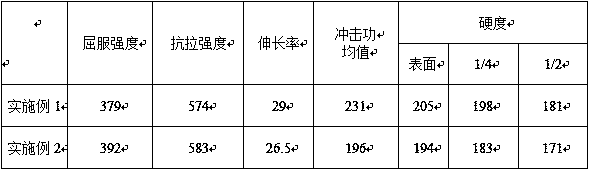

Embodiment 1

[0014] Embodiment 1: 22mm steel plate production method

[0015] Key process steps include:

[0016] 1) Converter steelmaking: Add 125t of molten iron and 30t of scrap steel into the converter for smelting, add 2532kg of silicon-manganese alloy and 108kg of aluminum-iron deoxidation, 300kg of lime, and 200kg of synthetic slag during tapping.

[0017] 2) Refining outside the furnace: add 400kg of lime, 300kg of synthetic slag, 300kg of silicon-manganese alloy, 0.17% of outbound C, 1.26% of Mn, and superheat of molten steel at 12-15°C.

[0018] 3) Continuous casting: the whole process is protected by argon gas, and the section of the billet is 260×2100mm.

[0019] 4) Heating: The temperature out of the furnace is 1163°C, and the time in the furnace is 251 minutes.

[0020] 5) Rolling: Stage I rolling temperature is 1106°C, intermediate billet is 80mm, stage II rolling temperature is 930°C, final rolling temperature is 836°C, and reddening temperature is 560°C.

[0021] 6) Acc...

Embodiment 2

[0023] Embodiment 2: 40mm steel plate production method

[0024] Key process steps:

[0025] 1) Converter steelmaking: Add 125t of molten iron and 30t of scrap steel into the converter for smelting, add 2709kg of silicon-manganese alloy and 98kg of aluminum-iron deoxidation, 300kg of lime, and 200kg of synthetic slag during the tapping process of the converter.

[0026] 2) Refining outside the furnace: add 500kg of lime, 380kg of synthetic slag, 326kg of silicon-manganese alloy, 0.20% of outbound C, 1.42% of Mn, and superheat of molten steel at 12-15°C.

[0027] 3) Continuous casting: the whole process is protected by argon gas. The billet section is 260×2100mm.

[0028] 4) Heating: The temperature out of the furnace is 1178°C, and the time in the furnace is 223 minutes.

[0029] 5) Rolling and cooling: The rolling temperature of the first stage is 1100°C, the intermediate billet is 80mm, the rolling start temperature of the second stage is 920°C, and the final rolling temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com