Deep trench planarization methods with different structures

A planarization method and deep trench technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as residue and excessive grinding surface, so as to improve yield, avoid defects, and improve the surface morphology of silicon wafers uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

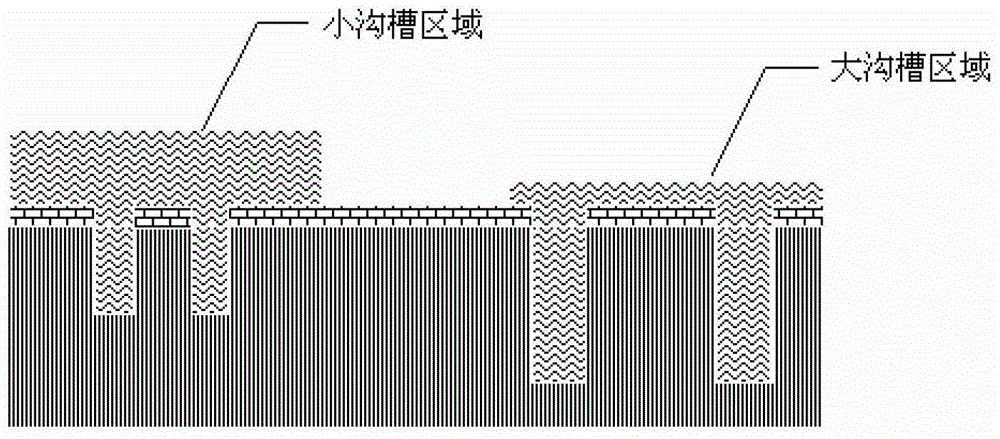

[0041] The deep trench planarization method with different structures of the present invention includes the steps:

[0042] 1) On the silicon substrate 1, use low pressure chemical vapor deposition (LPCVD), plasma enhanced chemical vapor deposition (PECVD) or atmospheric pressure chemical vapor deposition (APCVD) to deposit a layer with a thickness of 1000~10000 angstroms Barrier 2 (such as Figure 4 Shown);

[0043] The material of the barrier layer 2 is an oxide film (such as silicon oxide), a nitride film (such as silicon nitride), or a combination of an oxide film and a nitride film.

[0044] 2) Deposit a photoresist on the barrier layer 2. After development, dry or wet etch the barrier layer 2 to etch the barrier layer 2 to the silicon substrate 1, where the loss of the silicon substrate 1 is 100-300 Angstroms, preferably 100 Angstroms, exposing the silicon substrate 1 (such as Figure 5 Shown).

[0045] 3) On the silicon substrate 1, etch a variety of deep trench patterns with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com