Automatic saw blade polishing machine

A polishing machine and saw blade technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve the problems of high cost of saw blade processing, low degree of automation, and high labor intensity, and achieve Ensure the consistency of polishing thickness, high degree of automation, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

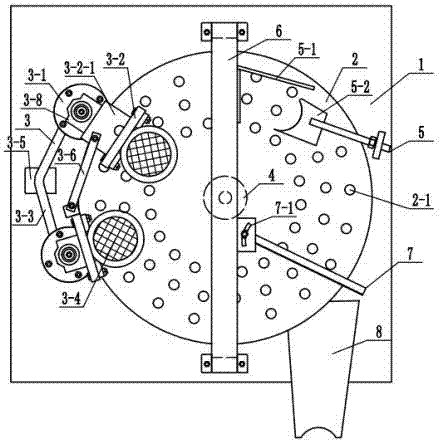

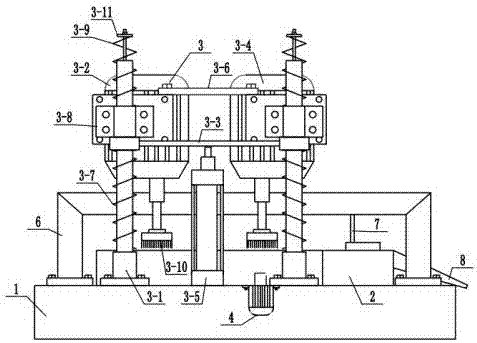

[0013] Depend on figure 1 , figure 2 It is known that a schematic diagram of an automatic saw blade polishing machine of the present invention consists of a lower platform 1, a turntable 2, a grinder assembly 3, a turntable drive motor 4, a limit assembly 5, a cross beam 6, a material shifting baffle 7, and a discharge trough 8 components, the turntable drive motor 4 is hoisted in the middle of the lower side of the lower platform 1, the center of the turntable 2 is connected and fixed with the turntable drive motor 4 and is located above the lower platform 1, the turntable drive motor 4 drives the turntable 2 to make a circular motion, and the cross beam 6 Installed longitudinally on the lower platform 1 and directly above the turntable 2, the grinding machine assembly 3 is installed above the lower platform 1 and on the left side of the cross beam 6, and the limit assembly 5 arc baffle 5-2 is installed on the lower platform 1 and on the turntable 2, the V-shaped baffle 5-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com