Sealing device with automatic compensation function

A sealing device and automatic compensation technology, applied in the direction of engine sealing, engine components, pipes/pipe joints/fittings, etc., can solve the problems of sealing ring seal failure, affecting the sealing effect, etc., to prolong the sealing life, the structure is simple and compact, The effect of good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

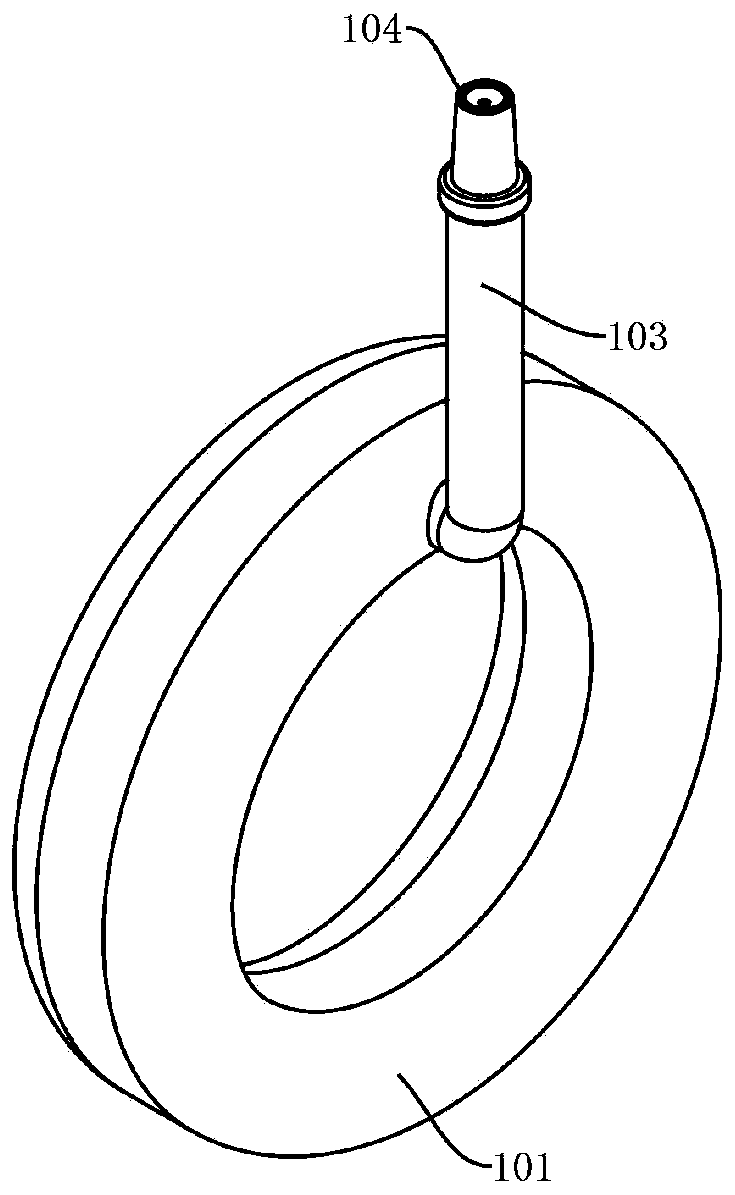

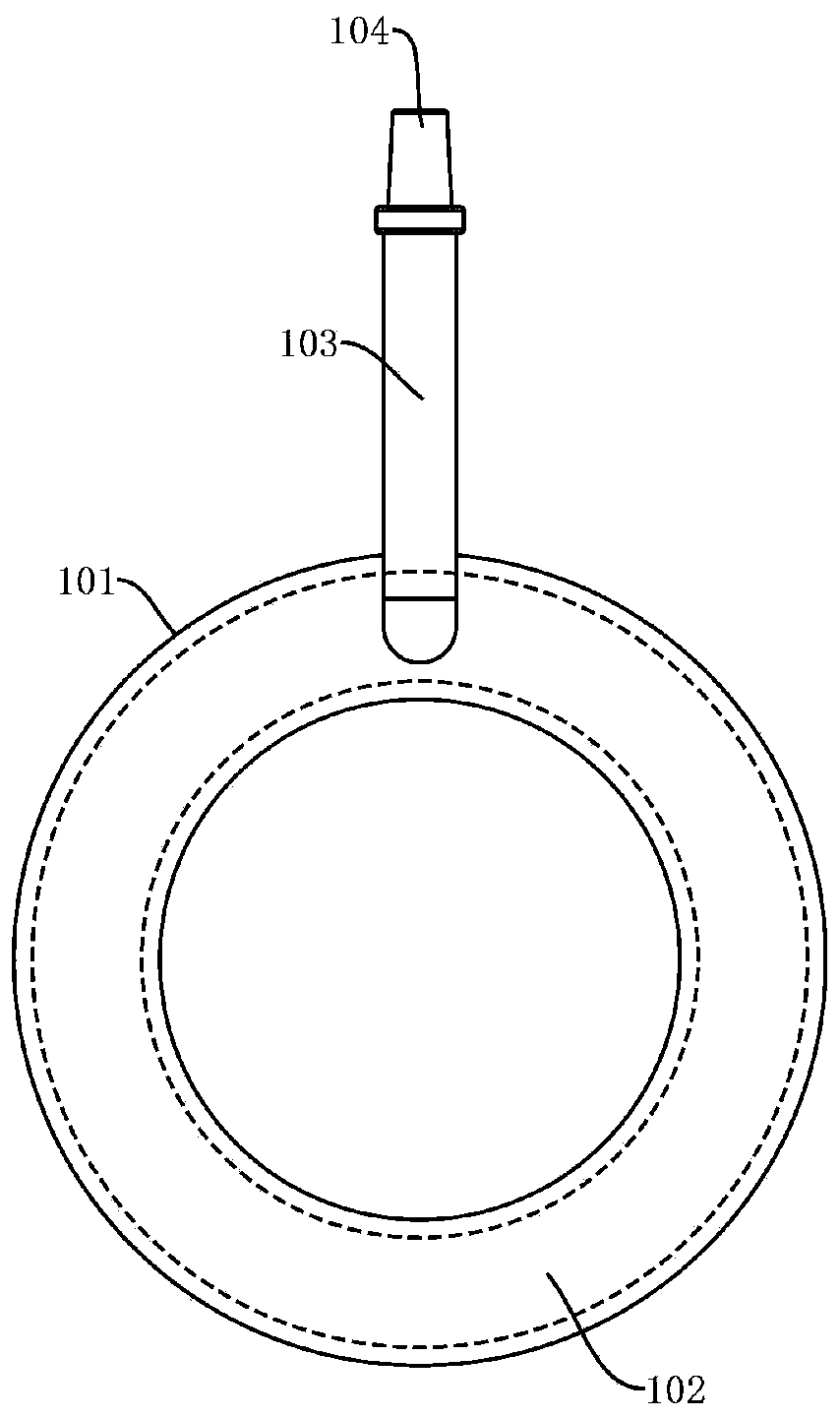

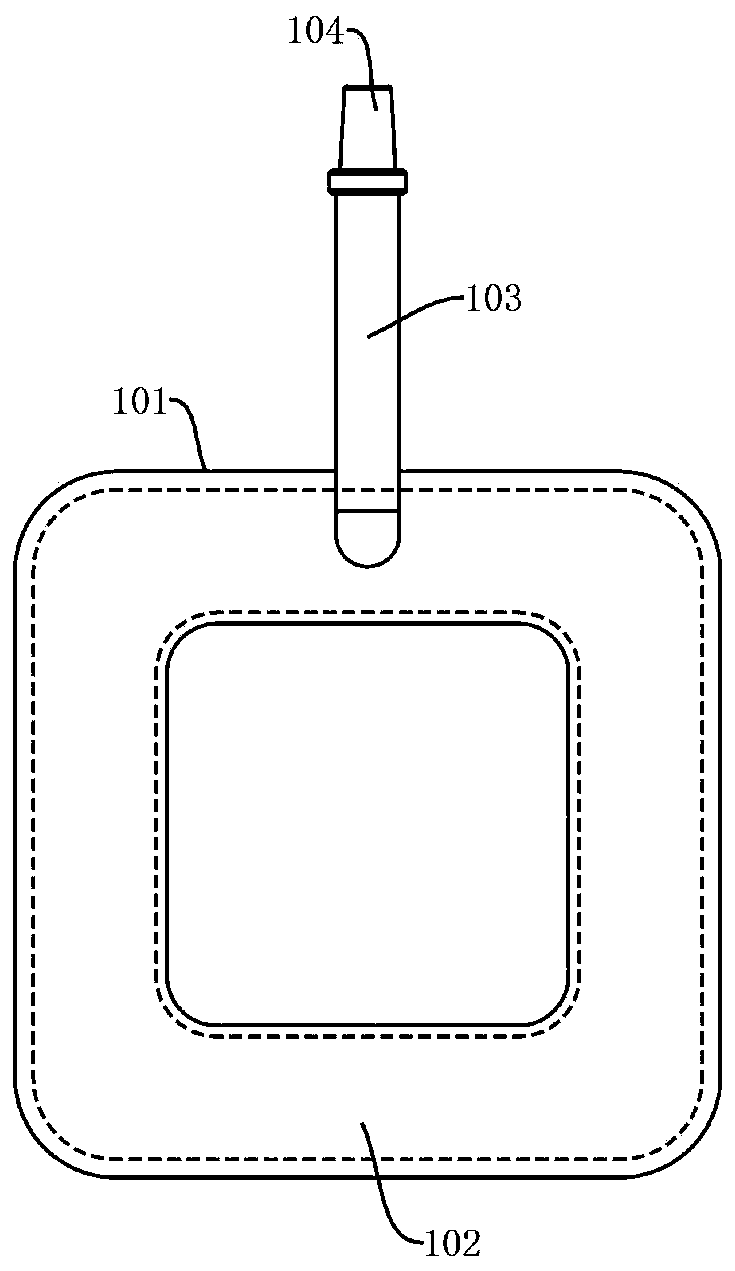

[0024] see figure 1 , figure 2 and Figure 4 In this embodiment, a sealing device with automatic compensation function is provided, including a flexible sealing body 101 for sealing and a pressure regulating part 104, and a pressure regulating cavity 102 is arranged in the flexible sealing body 101, and the regulating The pressure component 104 communicates with the pressure regulating cavity 102 and is used for regulating the pressure in the pressure regulating cavity 102 . In this embodiment, the user can use the pressure regulating component 104 to inject or extract gas or liquid into the pressure regulating cavity 102, thereby changing the pressure in the pressure regulating cavity 102 and maintaining the pressure in the pressure regulating cavity 102 , the flexible sealing body 101 has a certain degree of elasticity, and can properly expand and / or deform when the pressure in the pressure regulating cavity 102 changes; According to the requirements of sealing, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com