Adjustable oil pressure buffer with automatic compensation function

An oil pressure buffer and automatic compensation technology, which is applied in the direction of shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve the problem that the adjustable oil pressure buffer cannot meet the requirements of self-adaptive adjustment, and achieve high rigidity , Strong shock absorbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

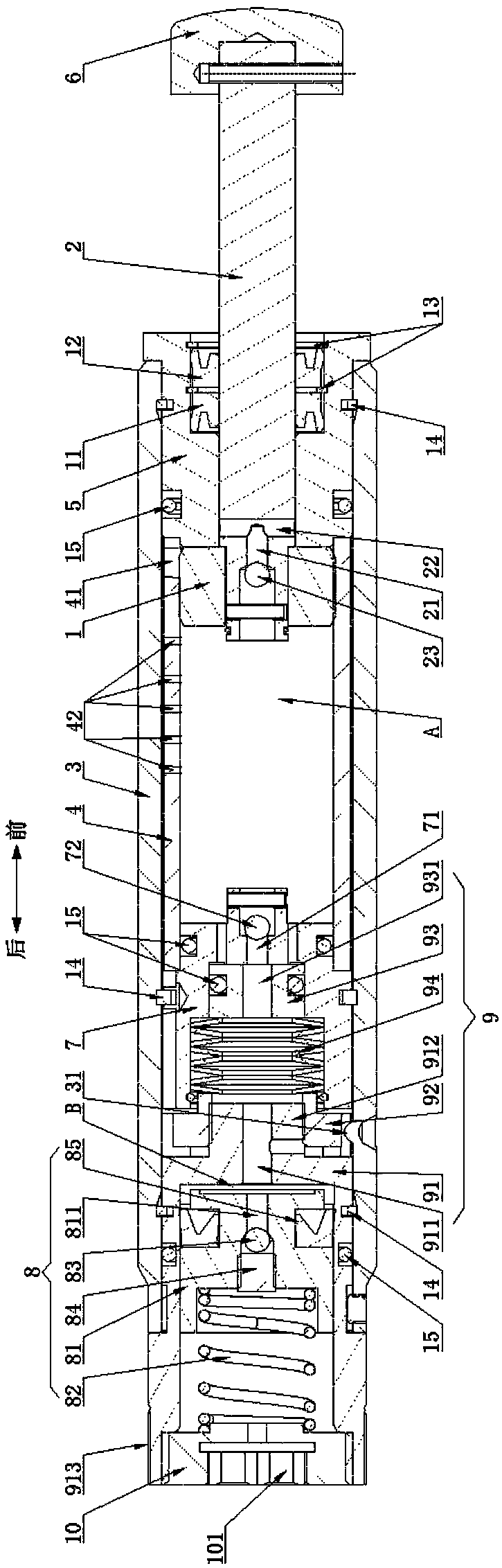

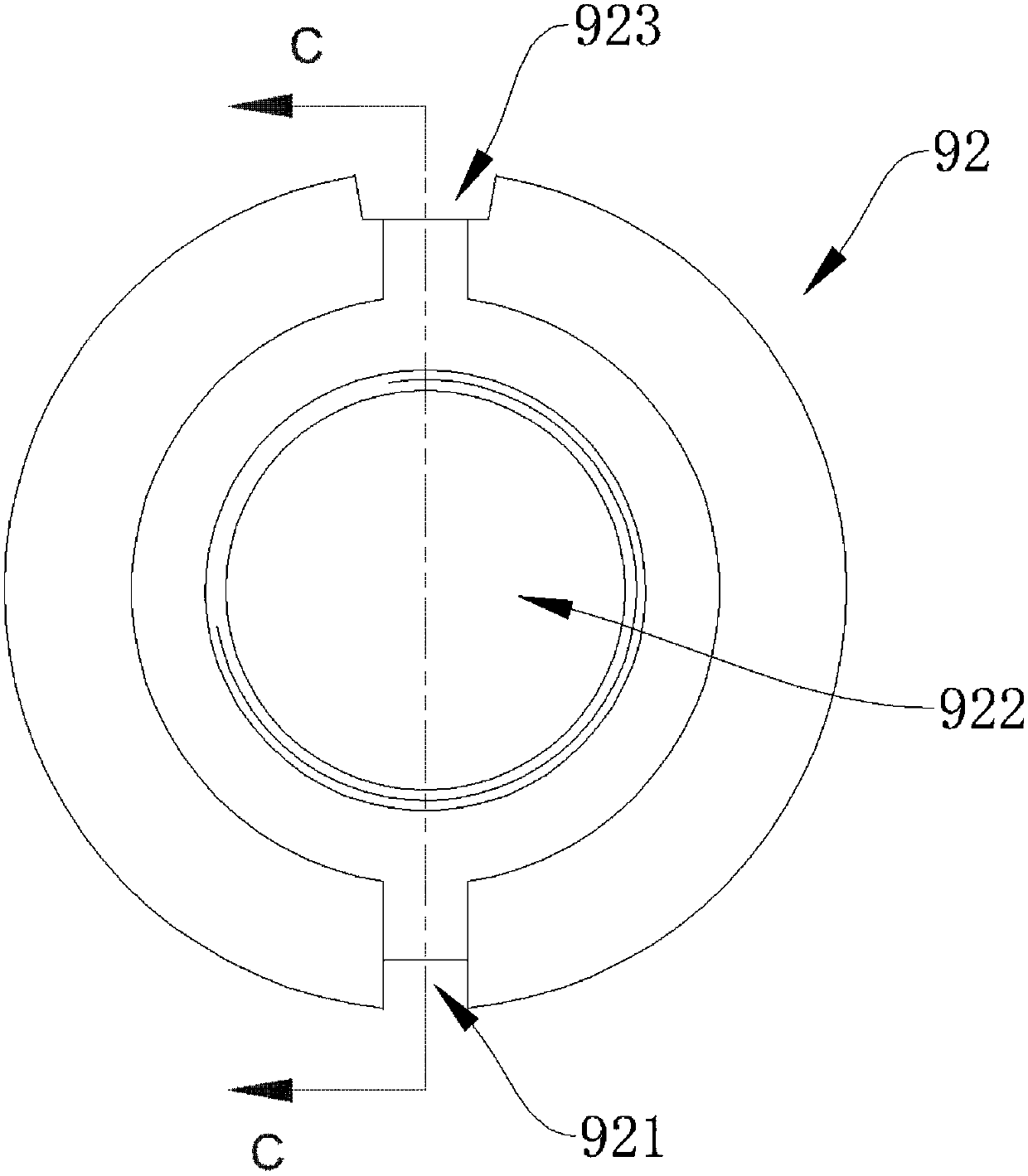

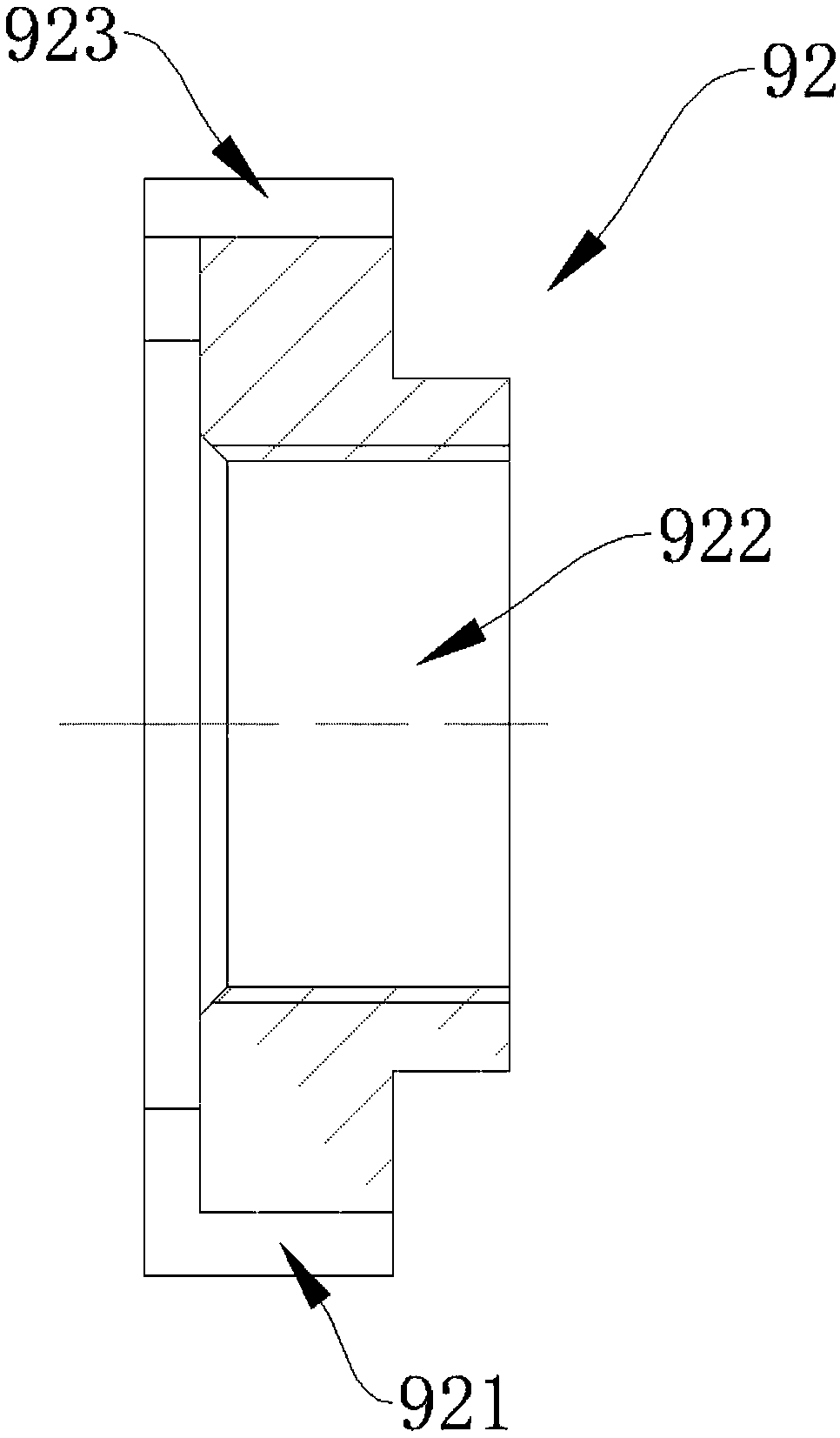

[0041] See figure 1 , figure 2 and image 3 , the present invention has an adjustable oil pressure buffer with automatic compensation function, which includes a piston 1, a piston rod 2, an outer tube 3 and an inner tube 4 set in the outer tube 3, the front end of the outer tube 3 is closed by a bearing 5, The piston 1 is movably installed on the front end side of the inner tube 4, and there is a gap between the outer circumference of the piston 1 and the inner peripheral wall of the inner tube 4. The front end of the piston rod 2 is fixedly connected with the impact head 6, and the rear end passes through the bearing. After 5, it is connected with the piston 1, and the rear end of the inner tube 4 is fixed with a back cover 7, and the inner cavity A formed between the back cover 7 and the piston 1 is filled with hydraulic oil, and the outer tube 3 is provided with a pressure accumulation structure 8. The gap formed between the outer wall of the inner tube 4 and the inner wal...

Embodiment 2

[0053] The difference between the second embodiment and the first embodiment is that an overflow hole 42 is provided on the wall of the inner tube 4. When the piston 1 is pushed by the piston rod 2 and moves toward the front end along the inner tube 4 Squeeze the hydraulic oil in the inner chamber A. When there is a gap between the front end face of the movable block 93 and the front end face 73 of the axially stepped hole of the back cover 7, that is, when the volume of the flow regulating cavity is zero, a part of the hydraulic oil After entering the flow regulating cavity through the flow regulating through hole 74, it enters the accumulator chamber B, and part of it enters the gap between the inner pipe 4 and the outer pipe 3 through the gap between the piston 1 and the inner wall of the inner pipe 4, and then flows into the accumulator chamber B. , and the other part enters the gap between the inner pipe 4 and the outer pipe 3 through the overflow holes 42 one by one and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com