Automobile driving system with motor rotating at constant speed

A vehicle drive system, a technology of constant speed rotation, applied in vehicle components, control devices, transportation and packaging, etc., can solve the problems of low cruising range, long battery charging time, and high power system energy consumption, reducing driving current, reducing The effect of starting current and increasing mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

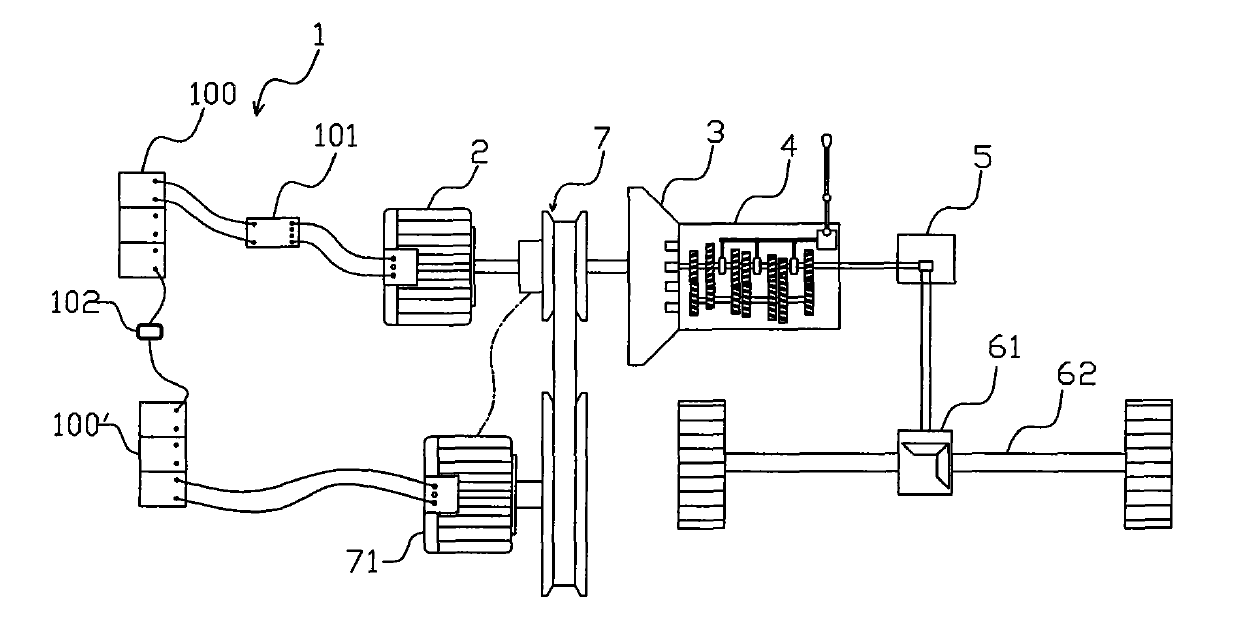

[0014] combine figure 1 As shown, an automobile drive system with a motor rotating at a constant speed includes a power supply system 1, a motor 2, a clutch 3, a transmission 4, and a differential 61 arranged in sequence. It rotates at a constant speed at a high speed of 1000 rpm; the clutch 3 is reversely clutched, that is, when the clutch pedal is stepped on, the motor 2 is combined with the transmission 4, and the power is transmitted to the vehicle drive system; when the clutch pedal is released, the motor 2 and the transmission The transmission 4 is separated, and the power generation system 7 is used to convert the kinetic energy into power generation energy, which is fed back to the storage battery in the power supply system 1 for electricity storage. Speed changer 4 further connects clutch 5, differential gear 61 and automobile rear axle 62, and then drives automobile to travel, can also be provided with a 90 ° steering transmission mechanism 5 between speed changer ...

Embodiment 2

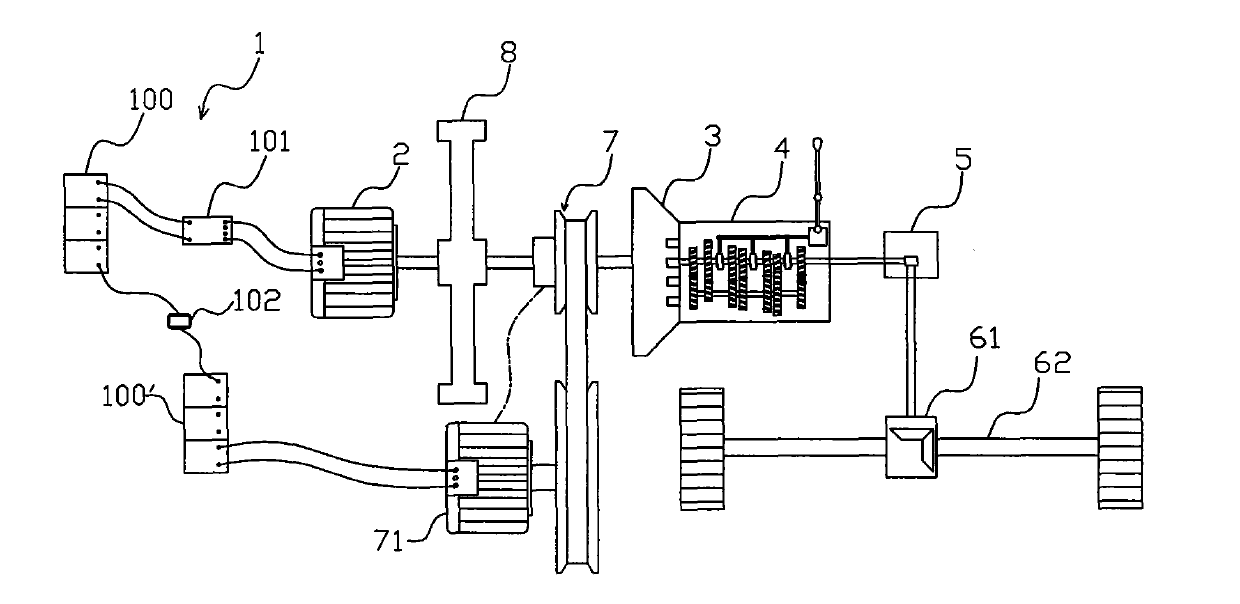

[0018] combine figure 2 As shown, an automobile drive system with a motor rotating at a constant speed includes a power supply system 1, a motor 2, a clutch 3, a transmission 4, and a differential 61 arranged in sequence. It rotates at a constant speed at a high speed of 1000 rpm; the clutch 3 is reversely clutched, and when the clutch pedal is stepped on, the motor 2 is combined with the transmission 4 to transmit power to the vehicle drive system; when the clutch pedal is released, the motor 2 is connected to the transmission 4 is separated, and the kinetic energy is converted into power generation energy by the power generation system 7, which is reversely supplied to the storage battery in the power supply system 1 for electricity storage. Speed changer 4 further connects clutch 5, differential gear 61 and automobile rear axle 62, and then drives automobile to travel, can also be provided with a 90 ° steering transmission mechanism 5 between speed changer 4 and differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com