Retaining wall type caisson sinking device and its construction method

A technology for caissons and inner retaining walls, applied in caissons, infrastructure engineering, buildings, etc., can solve problems such as difficult sinking, inclination, and difficult deviation correction, and achieve the effects of convenient subsequent excavation, simple construction technology, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention will be further described below in conjunction with the accompanying drawings.

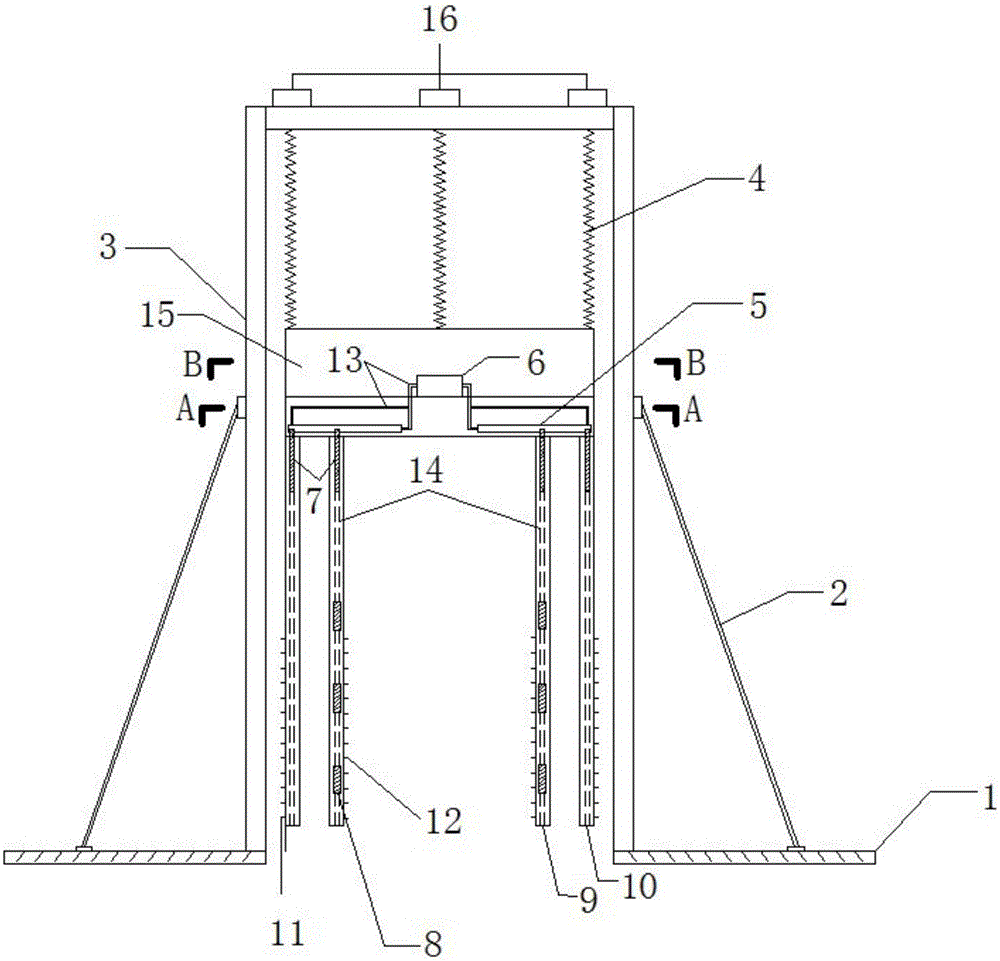

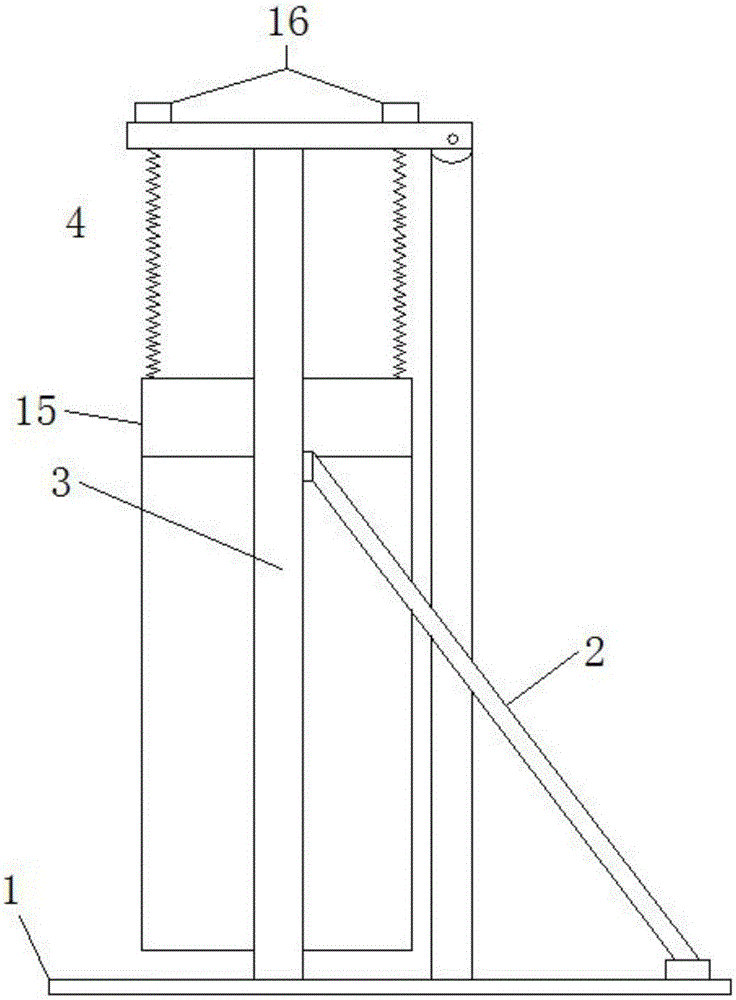

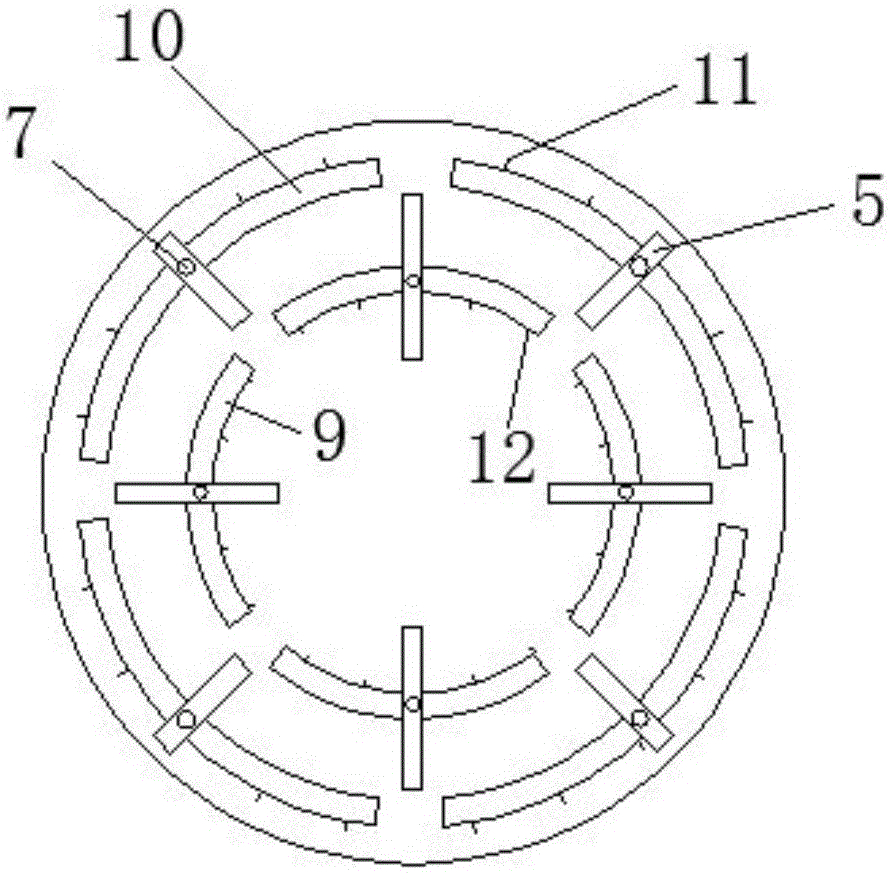

[0039] Such as Figure 1 to Figure 4 As shown, a protective wall type caisson sinking device of the present invention includes a portal support unit, a deviation correction unit, a sinking aid unit and an auxiliary unit.

[0040] Specifically, the portal support unit includes an equipment foundation 1, a side support frame 2 and a portal support 3, the lower part of the side support frame 2 is hinged to the equipment foundation 1, the upper part of the side support frame 2 is hinged to the portal support 3, and the portal support unit It mainly plays the functions of fixing and moving equipment, bearing the opening and closing force of equipment, and placing auxiliary equipment. The equipment foundation 1 is a rectangular platform of 20m×20m with a height of 1.5m. The well sinking device is moved, and the portal support 3 is 40m high, and its top is a rectangular platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com