Method for in-hole guiding deviation rectification and steel pipe column straightening based on one-column-one-pile back insertion method

A steel pipe column and internal guide technology, applied in infrastructure engineering, construction, etc., can solve the problems of short straightening process force arm, low work efficiency, difficult adjustment, etc., achieve significant improvement in work efficiency, improve straight work efficiency and accuracy, and equipment Make easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

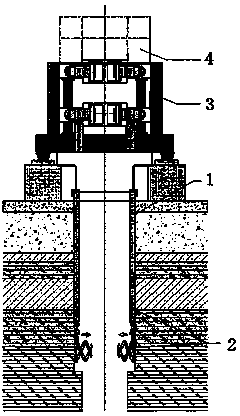

[0038] Such as Figure 1 to Figure 6 As shown, the method of guide deviation correction in the hole and steel pipe column straightening based on the post-insertion method of one column and one pile of the present invention, its construction steps are:

[0039] (1) Remove the drilling rig and clean the hole

[0040] After the lower supporting piles are poured, the drilling rig is removed, the hole is cleaned, and steel plates are laid around the hole;

[0041] (2) Install the guiding and correcting device in the casing

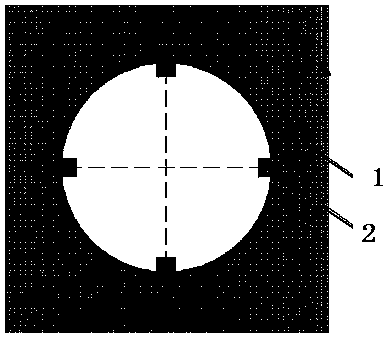

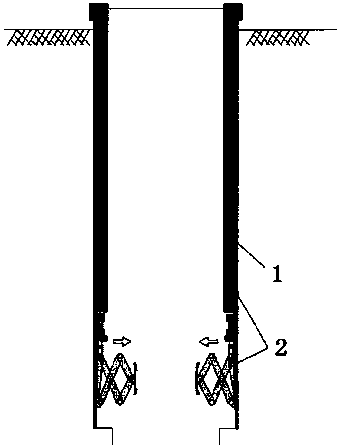

[0042] Install four pairs of guiding and correcting devices 2 in the 6m long steel casing 1, and the guiding and correcting devices 2 are symmetrical, vertically arranged and fixed firmly; figure 1 ;

[0043] (3) Connect the hydraulic oil pipe

[0044] Connect each pair of guiding and correcting devices with the matching oil pipe 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com