A cast-in-place hollow floor with holes formed by combining steel mesh and inflatable pipes

A hollow floor and air-filled tube technology, which is applied in the field preparation of floors and building components, formwork/formwork/working frames, etc., can solve problems such as large buoyancy, poor compatibility, and lack of floor crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

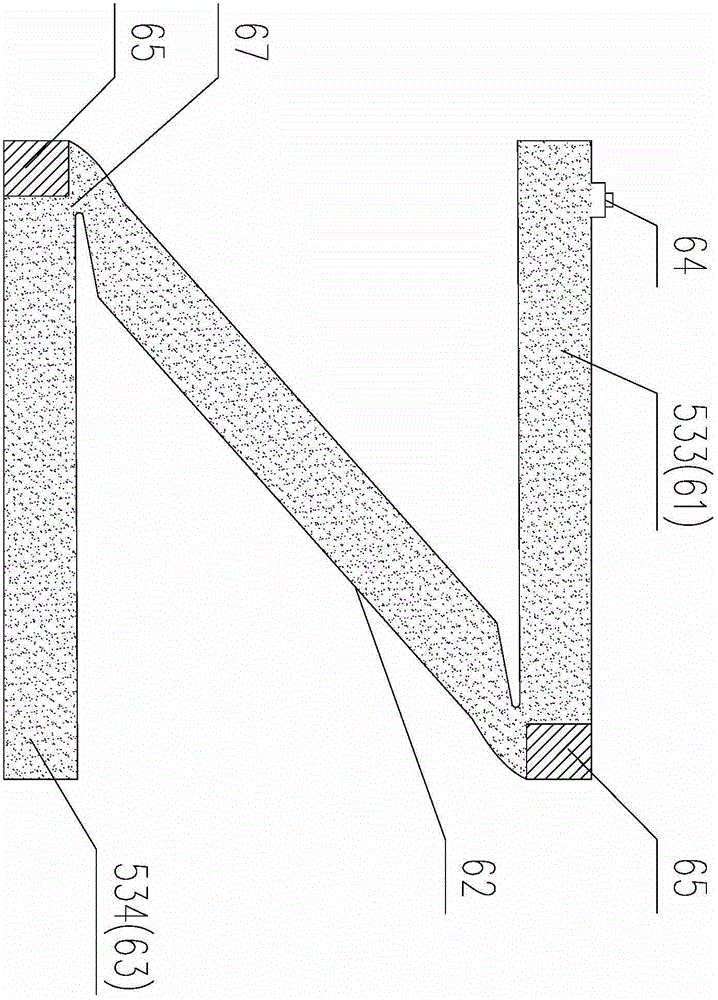

[0026] The invention will be further described below in conjunction with the accompanying drawings.

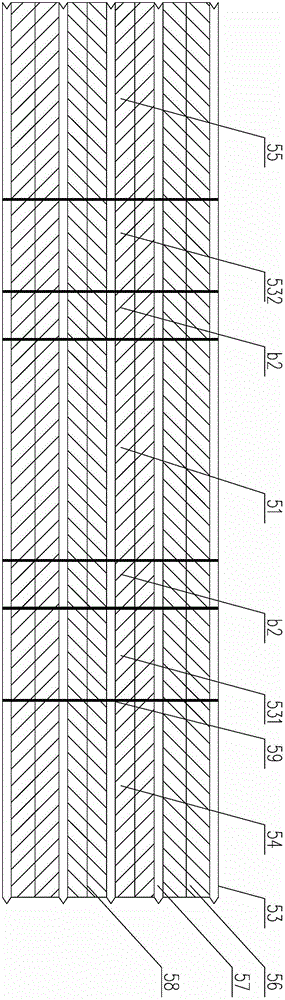

[0027] figure 1 It is a structure diagram of the steel mesh of the steel mesh and the gas-filled tube combined box body of the first embodiment of the present invention. like figure 1 As shown, the steel mesh of steel mesh and inflatable tube combination box 5 contains mesh plate 56 and reinforcing rib 57 and connecting plate 58 and side rib 53, and mesh plate 56 and reinforcing rib 57 and connecting plate 58 and side rib 53 form The overall structure of interaction; the steel mesh reinforcement rib 57 is pressed with rows of bending lines 59 in the vertical direction; the steel mesh is determined by the bending lines 59 to make the bottom 51 of the box, and the chord edge b 2 , The box body side wall 531 and the side wall 532, the box top 54 and the box top 55 length.

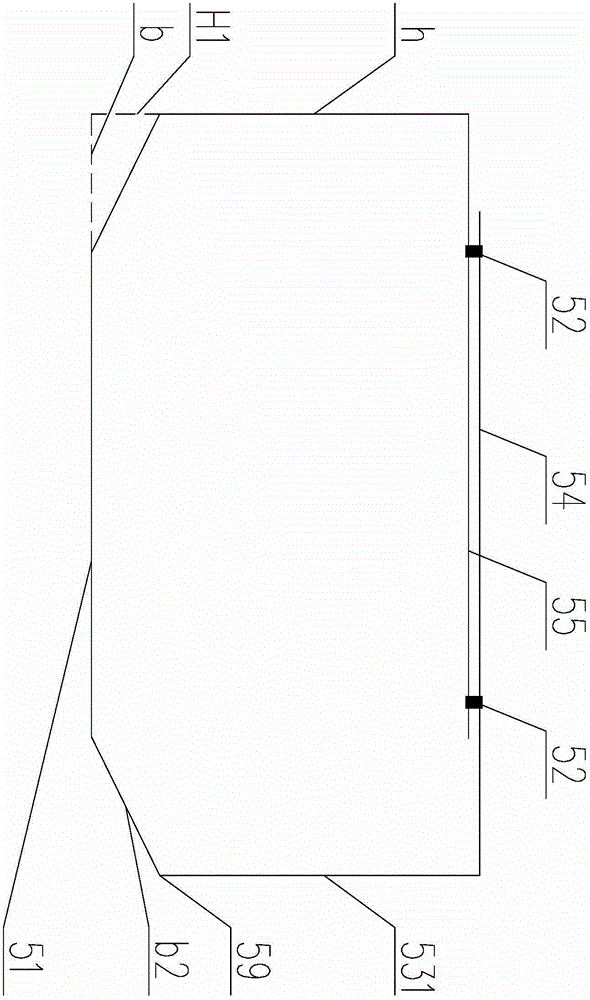

[0028] figure 2 It is a converted cross-sectional view of the steel mesh of the steel mesh and the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com