Method for determining maximum deflection value of pre-stressed circular thin film under uniformly distributed load

A technology of evenly distributed load and maximum deflection, applied in the direction of measuring devices, instruments, etc., can solve problems such as loss of instrument accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

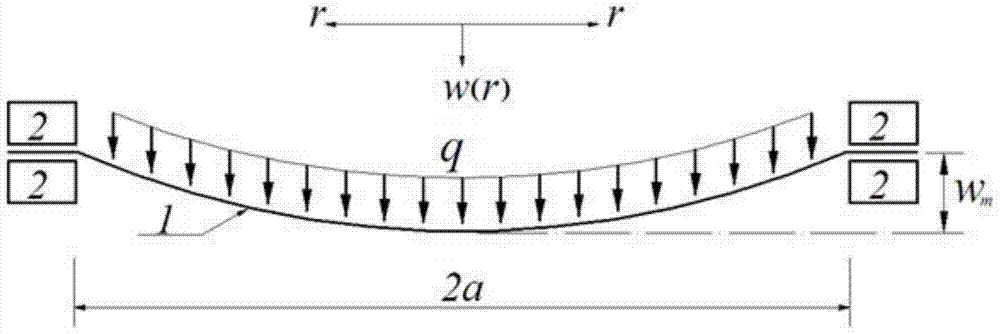

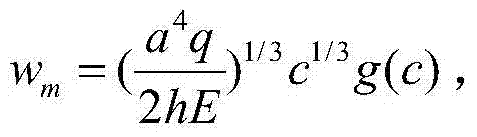

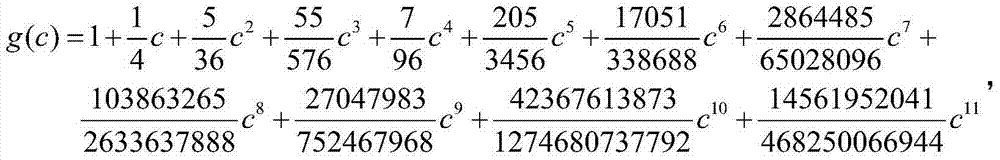

[0018] Such as figure 1 As shown, the radius is a, the thickness is h, Young’s modulus of elasticity is E, Poisson’s ratio is ν, and the prestress is σ 0 The circular film is fixed and clamped at its circumference, and a transverse uniform load q is applied to it, then based on the static force balance analysis of the axisymmetric deformation problem of this circular film, using the load measurement value q, the maximum deflection value of the film w m can be determined by the following formula:

[0019] w m = ( a 4 q 2 hE ) 1 / 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com