A multifunctional v-belt torque fatigue testing machine

A fatigue testing machine and multi-functional technology, applied in the field of V-belt fatigue testing machine and multi-functional V-belt torque fatigue testing machine, can solve the problems of inaccurate signal acquisition and immature technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

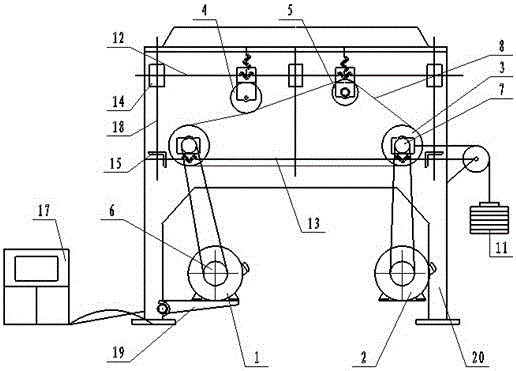

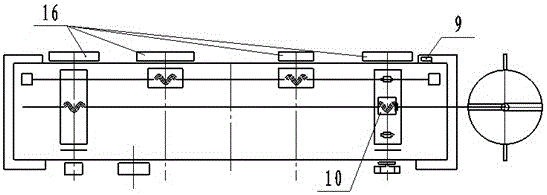

[0011] A multifunctional V-belt torque fatigue testing machine is composed of 22Kw frequency conversion motor 1, 30Kw DC motor 2, inspection pulley 3, No. 1 pressure pulley 4, No. 2 pressure pulley 5, driving pulley 6, driven pulley 7 , inspection belt 8, displacement sensor 9, torque sensor 10, weight 11, upper linear guide rail 12, lower linear guide rail 13, linear bearing 14, guide rail bracket 15, transmission wheel set 16, electric control cabinet 17, vertical guide rail 18, Suspension motor bracket 19, body 20, guide wheel 21, electric heating constant temperature box 22, characterized in that: the suspension motor bracket 19 is connected to the left side bracket of the body 20, and there is a 22Kw frequency conversion motor 1 on the suspension motor bracket 19, 30Kw DC The motor 2 is directly fixed on the body 20, and two guide rail brackets 15 are fixed on both sides of the body 20. The guide rail bracket 15 fixes a lower linear guide rail 13 and three vertical guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com