Foldable cast-in-place wall splicing mold

A technology of cast-in-place walls and molds, which is applied to the preparation of formwork/formwork components, formwork/formwork/work frames, and building components on site, and can solve unfavorable construction efficiency, low work efficiency, and prefabricated partition panels. Problems such as large size can reduce the difficulty of construction, facilitate mobile positioning, and save manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

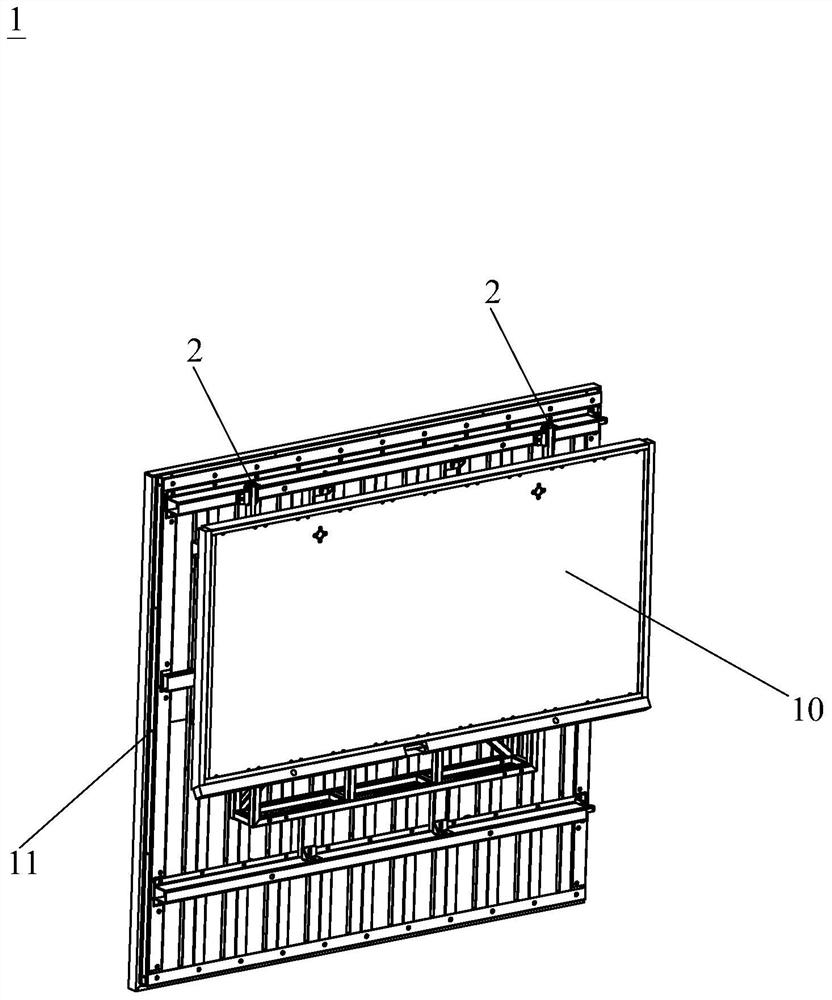

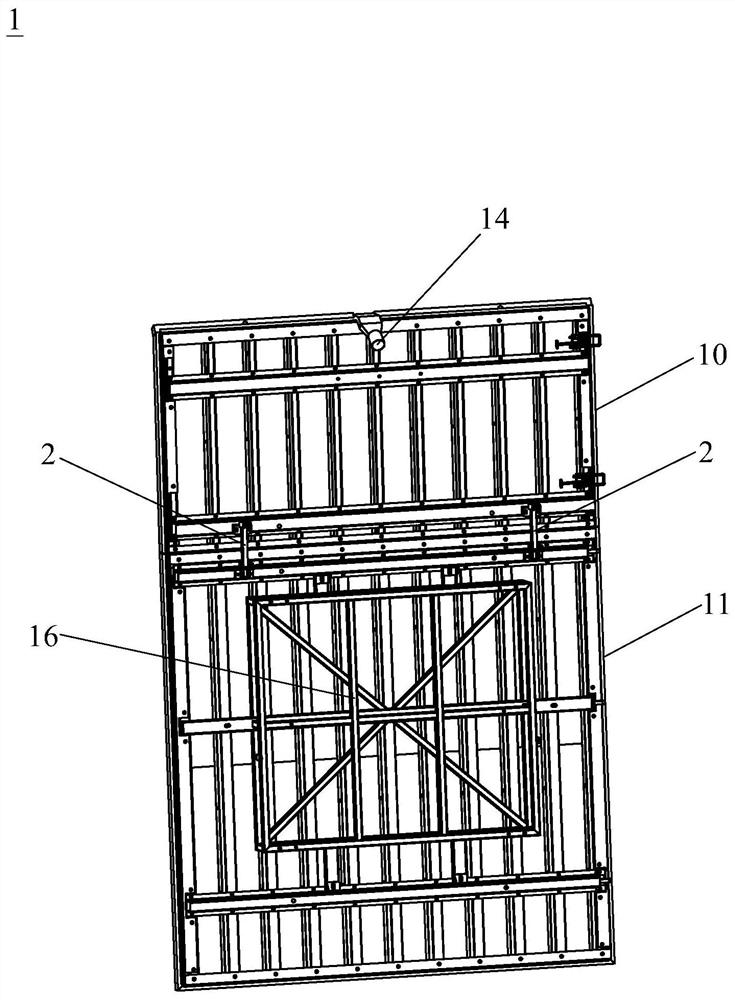

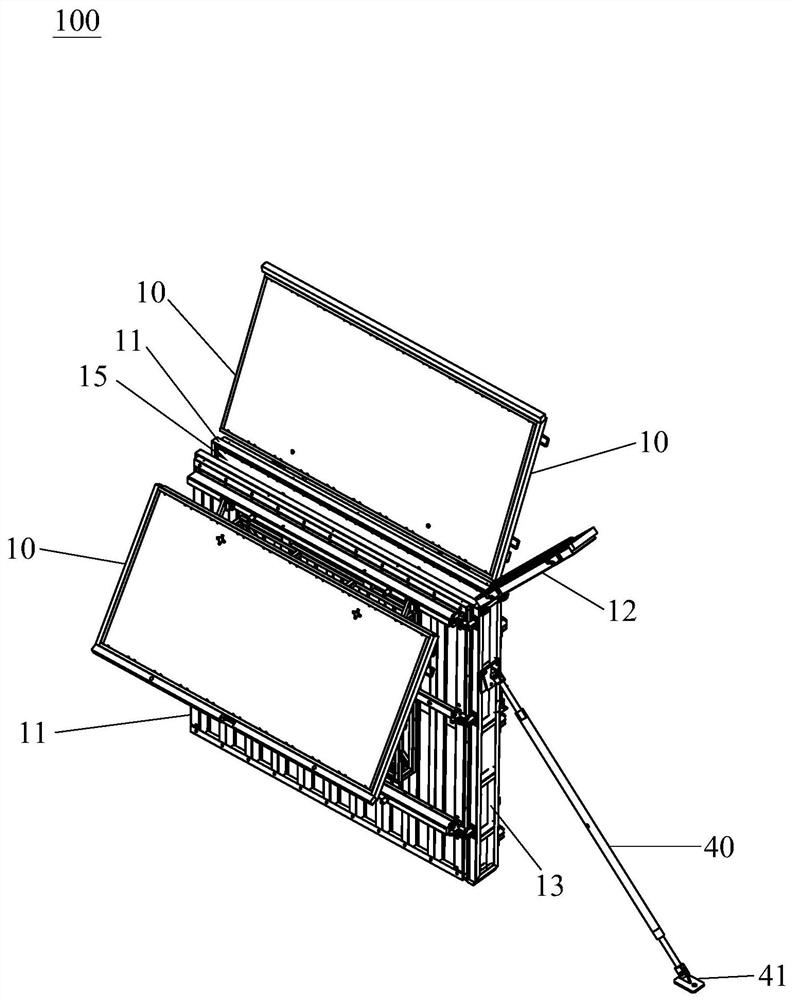

[0022] This embodiment discloses a foldable cast-in-place wall assembly mold, which uses an assembly structure to divide the entire mold into several different parts, specifically, as Figure 1 to Figure 4 , the mold includes an upper mold 10 , a lower mold 11 , an upper side baffle 12 and a lower side baffle 13 . The lower mold 11 is a plate body of a standard size, that is, the lower mold 11 is a standard part, which is the main part of the mould. The upper mold 10 is a plate body of a non-standard size adapted to on-site construction requirements. The upper edge of the upper mold is pivotally connected by a pivot member 2, and by this pivot member 2, the upper mold 10 can rotate 90° relative to the lower mold 11, so that the upper mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com