Self-calibration method of TDLAS (Tunable Diode Laser Absorption Spectroscopy) gas detection system

A gas detection system and detection system technology, which are applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of insufficiency of special calibration equipment, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

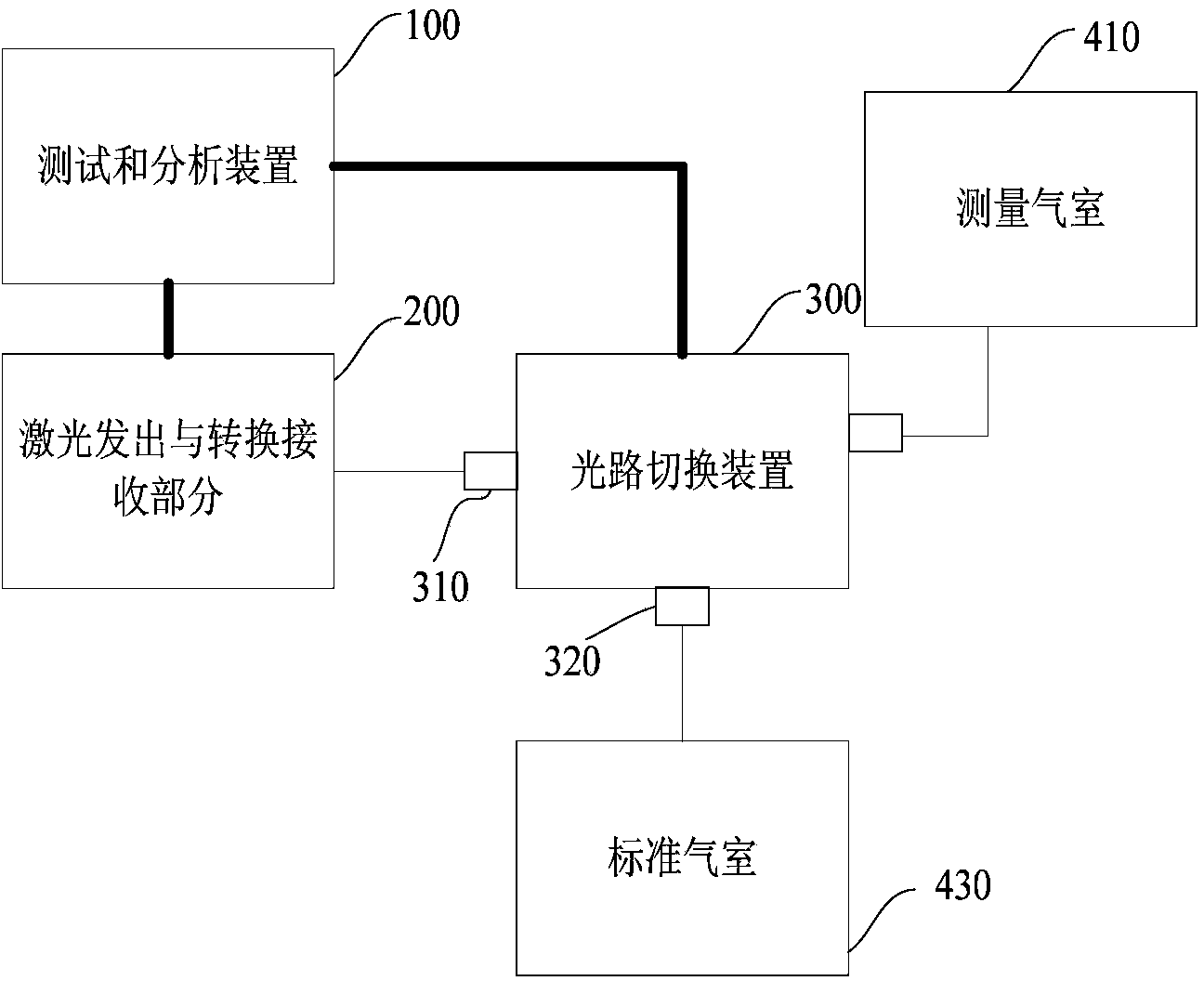

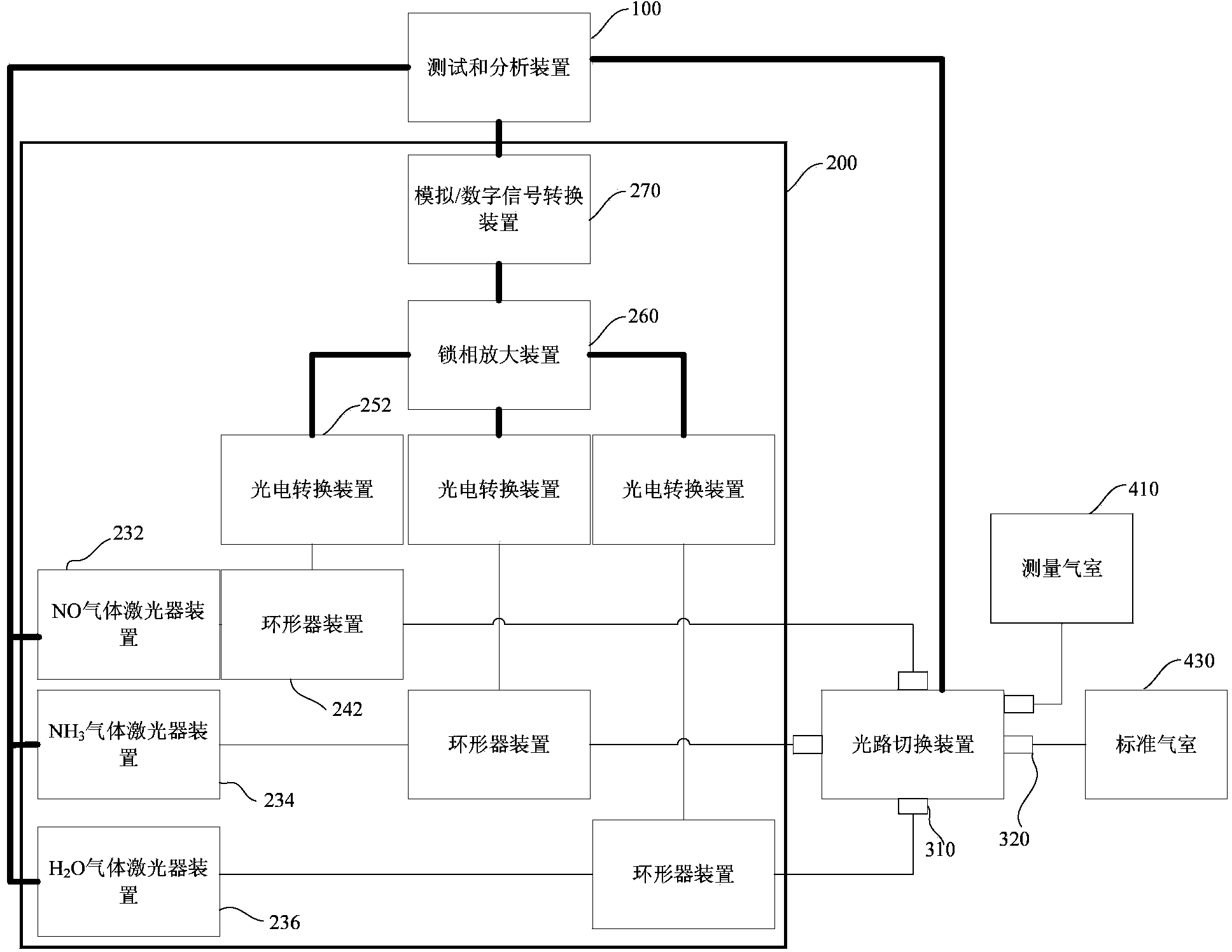

[0028] Embodiment 1 discloses a self-calibration method of a distributed TDLAS gas detection system, which is applied to a TDLAS gas detection system, please refer to figure 1 , the detection system includes a laser emitting and converting receiving part 200, a testing and analyzing device 100, an optical path switching device 300, and at least one standard gas chamber 430; wherein each standard gas chamber is filled with a target gas.

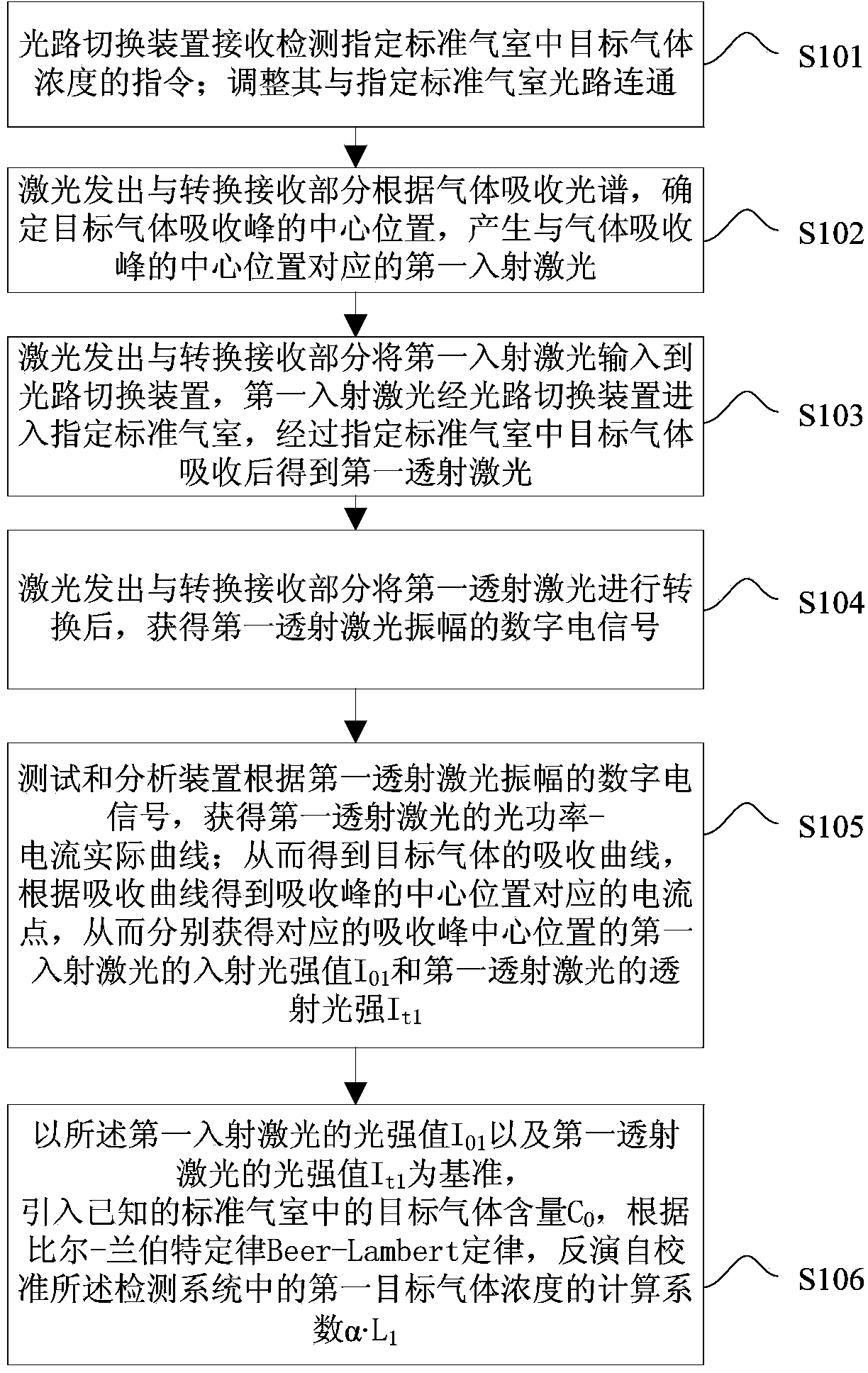

[0029] Please refer to figure 2 , the calculation coefficient α L of the target gas concentration in the self-calibrating detection system 1 , the method used includes the following steps:

[0030] S101, the optical path switching device 300 receives an instruction to detect the concentration of the target gas in the designated standard gas chamber, and adjusts its optical path communication with the designated standard gas chamber 430;

[0031] S102, the laser emitting and converting receiving part 200 determines the center position of the...

Embodiment 2

[0058] Example 2, please refer to figure 1 The TDLAS gas detection system using this method further includes at least one measuring gas chamber 410, which is connected to the output end 320 of the optical path switching device.

[0059] Please refer to Figure 5 , the method in embodiment 2 also includes the step of measuring the target gas concentration in the specified measurement gas chamber: taking the measurement of the target gas concentration of NO gas in the measurement gas chamber 410 as an example, the TDLAS gas detection system corresponding to NO Calculation coefficient of gas concentration α·L 1 Rear,

[0060] S201, the optical path switching device 300 receives an instruction for detecting the concentration of NO gas in the measurement gas chamber 410; adjusts the optical path communication between the optical path switching device 300 and the measurement gas chamber 410;

[0061] S202, the laser emitting and converting receiving part 200 determines the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com