Device for evaluating foaming property of air-soluble surface active agent and application of device

一种表面活性剂、气溶性的技术,应用在评价气溶性表面活性剂起泡性能的装置领域,能够解决可注性差、二氧化碳泡沫不稳定等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

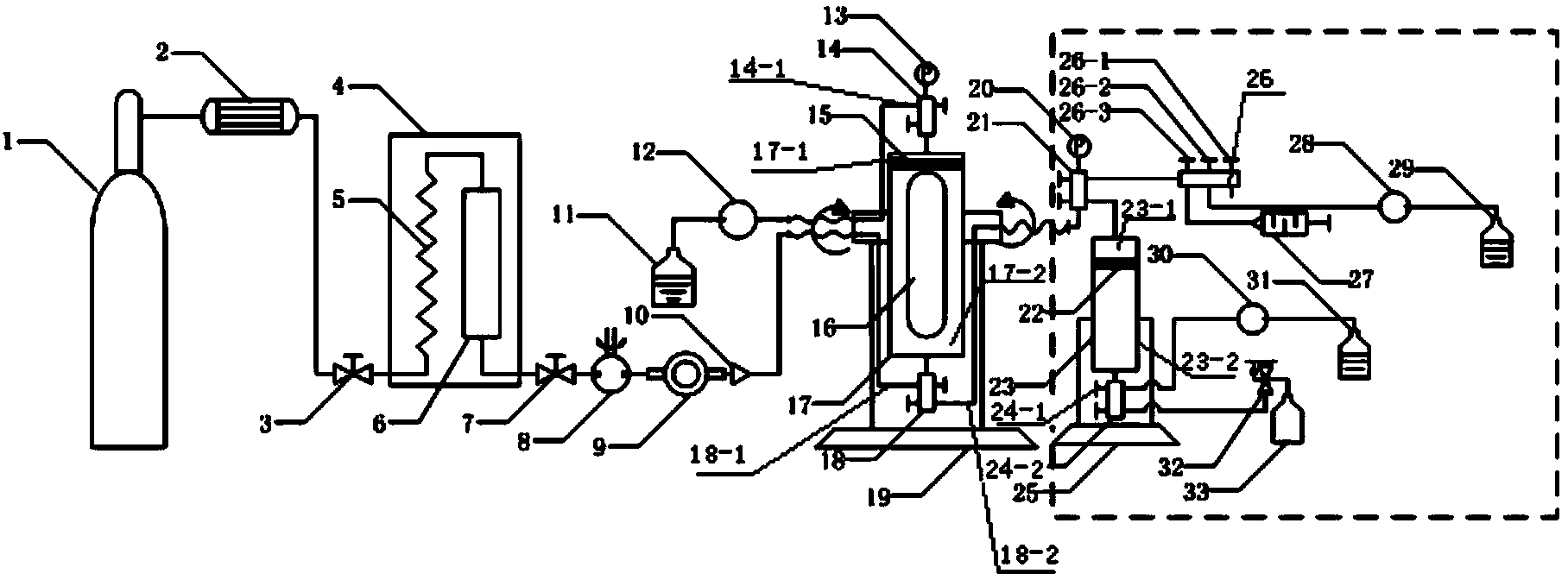

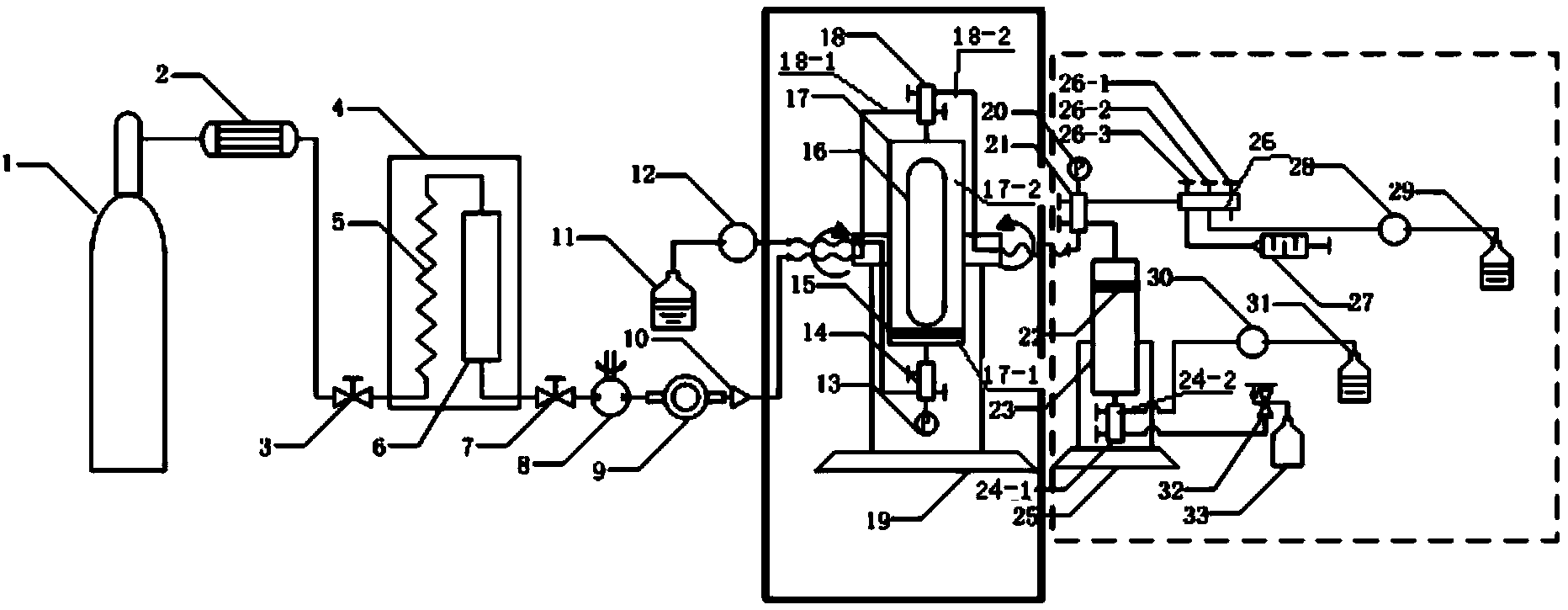

[0065] A device for evaluating the foaming performance of an air-soluble surfactant, including a gas source part, an evaluation kettle, a liquid part and an intermediate container part;

[0066] The gas source part includes a carbon dioxide gas source;

[0067] The evaluation kettle 17 includes a cylindrical kettle body, a first piston 15 is arranged in the cylindrical kettle body, a first group of valves 14 and a second group of valves are respectively arranged at both axial ends of the cylindrical kettle body. Valve 18, the first piston 15 divides the cylindrical kettle body into a displacement chamber 17-1 and a mixing chamber 17-2, wherein the displacement chamber 17-1 is connected to the first advection chamber through the first set of valves 14 The pump 12 is connected to the first liquid storage tank 11, and the mixing chamber 17-2 is respectively connected to the gas pipeline 18-1 and the liquid pipeline 18-2 through the second group of valves 18, and the gas pipeline ...

Embodiment 2

[0073] A device for evaluating the foaming performance of gas-soluble surfactants as described in Example 1, the difference is that the liquid carbon dioxide source includes a carbon dioxide cylinder 1, a dryer 2 and a refrigeration unit connected in sequence, and the refrigeration unit It includes a refrigerating cabinet 4 , a coil pipe 5 and a high-pressure storage tank 6 arranged in the refrigerating cabinet 4 .

Embodiment 3

[0075] A device for evaluating the foaming performance of gas-soluble surfactants as described in Example 1, the difference is that a first base 19 is installed at the bottom of the evaluation kettle 17, and the first base 19 drives the columnar The kettle body rotates along the horizontal axis; the pipelines respectively connected to the evaluation kettle 17 are all flexible pipelines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com