Electric energy meter correction table and electric energy meter correction method

A technology of electric energy meter and meter calibration table, applied in the direction of measuring electrical variables, measuring devices, instruments, etc., can solve the problems of low adjustment efficiency, increasing the equipment and space required for adjustment, disrupting the rhythm of production lines, etc. The effect of high efficiency, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

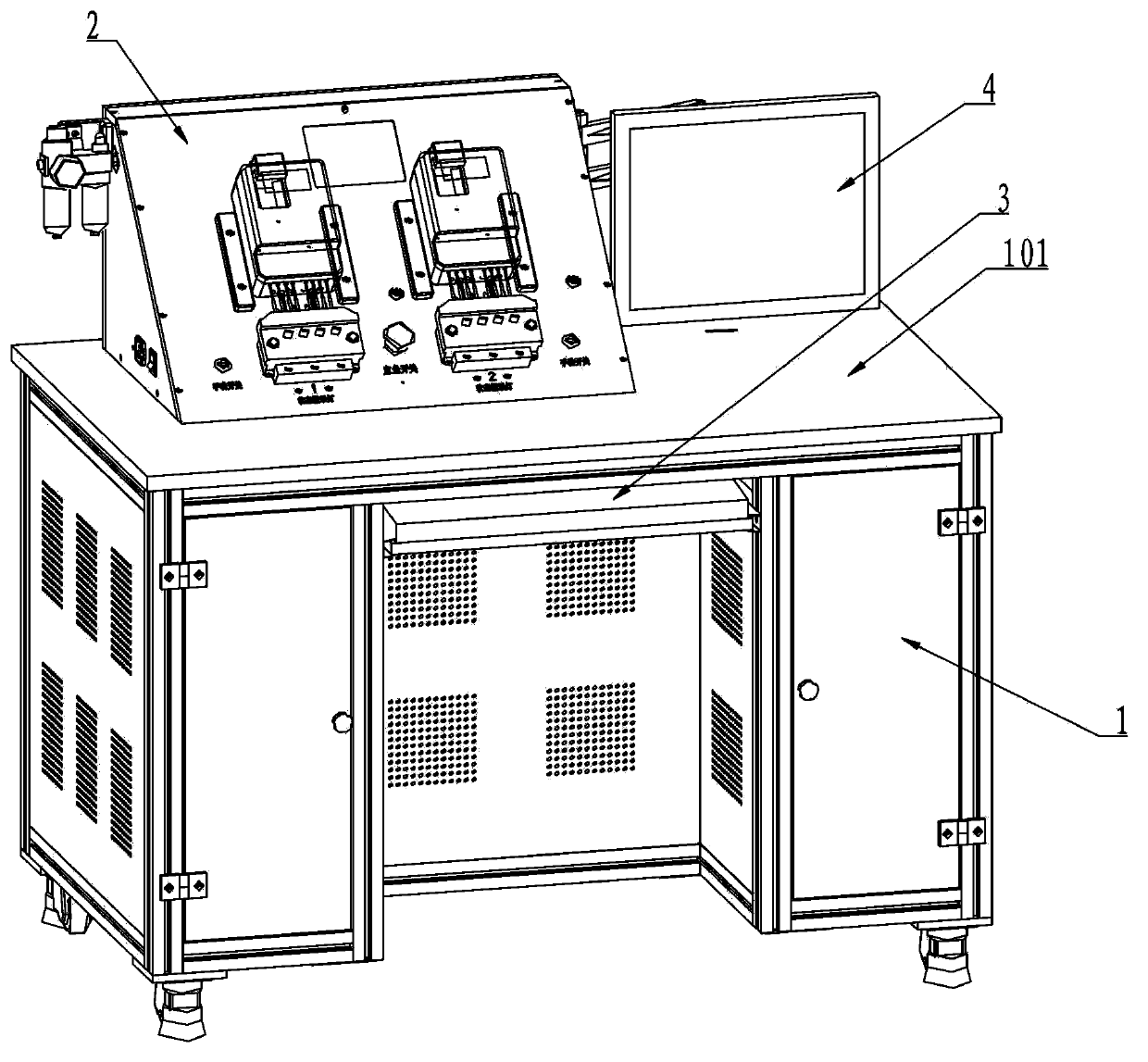

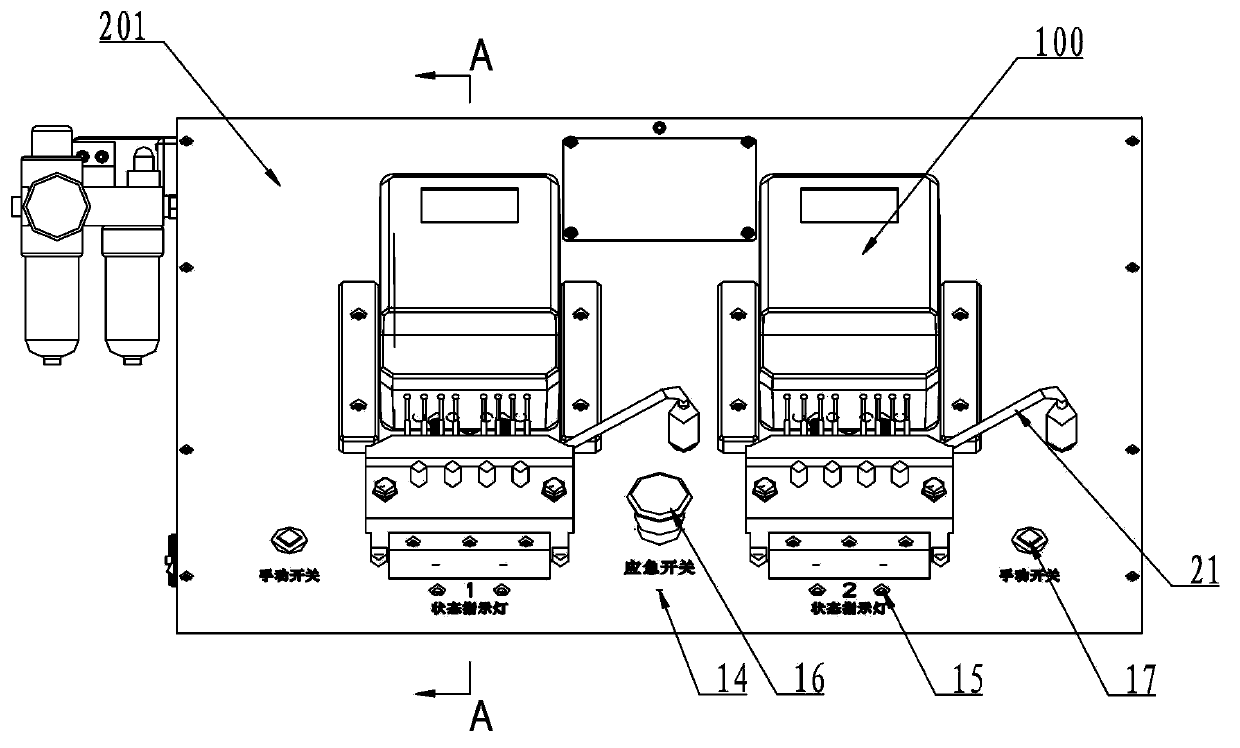

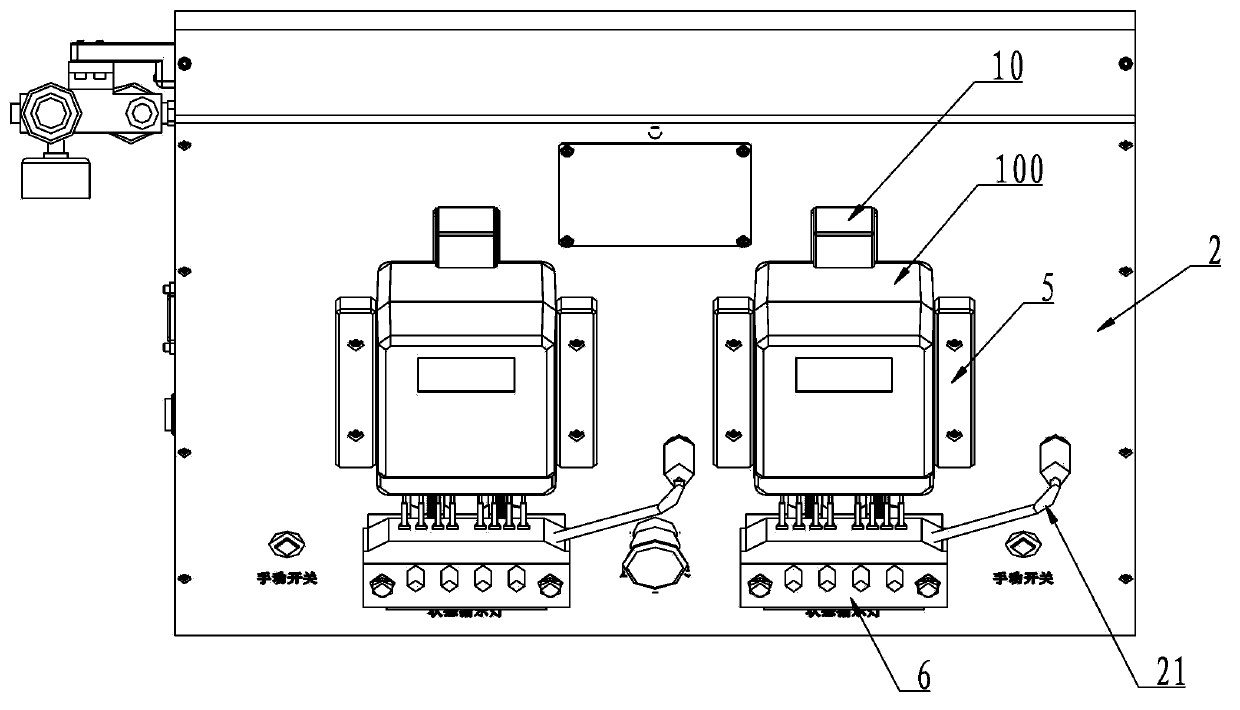

[0031] exist Figure 1 to Figure 10 In the illustrated embodiment of the electric energy meter calibration platform of the present invention, the electric energy meter calibration platform includes a workbench 1 and an operation platform 2 . The console 2 is fixed on the platen 101 of the workbench, and the front of the console 2 is a panel 201 inclined backward by 45°.

[0032] The host 20 of the PC, the power supply 18 (including the power supply circuit of the electric energy meter), and the control board 19 (the control unit composed of the single-chip microcomputer and peripheral circuits) are installed in the cabinet at the bottom of the workbench 1, and the keyboard 3 of the PC is placed on the workbench platen Below 101 , the monitor 4 of the PC is fixed on one side of the console 2 .

[0033] There are two epitopes 201a on the panel 201, and the two epitopes can be operated simultaneously or separately. Each meter position 201a is equipped with two guide blocks 5 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com