A kind of dye-sensitized solar cell composite counter electrode and preparation method thereof

A technology for solar cells and dye sensitization, which is applied in the field of solar energy utilization, can solve the problems of small active area of electrodes and cannot be used on a large scale, and achieves the effects of simple preparation, low price, and price avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

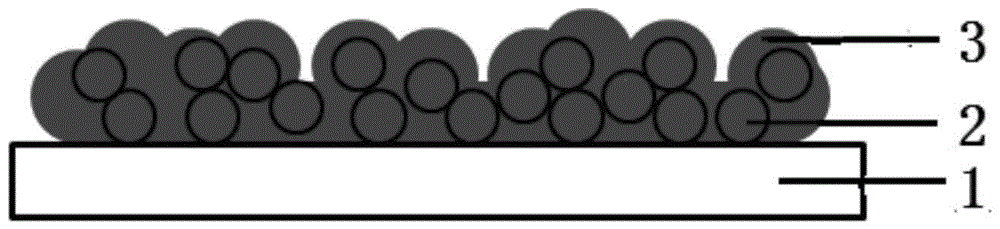

[0035] The composite PEDOT counter electrode is based on FTO conductive glass 1, and the mass ratio of ATO nano conductive powder, terpineol, ethyl cellulose, lauric acid and ethanol is 1:6:0.3:0.1:15 and mixed evenly to obtain ATO slurry. Take 100 microliters of ATO slurry, set the speed of the homogenizer to 2000 rpm, and last for 30 seconds to obtain an ATO film with a uniform thickness on the conductive glass substrate 1 . Subsequently, the prepared ATO membrane was sintered at a temperature of 450 degrees Celsius for 30 minutes to remove the non-conductive powder in the ATO membrane to obtain a support layer 2 composed of an ATO porous membrane.

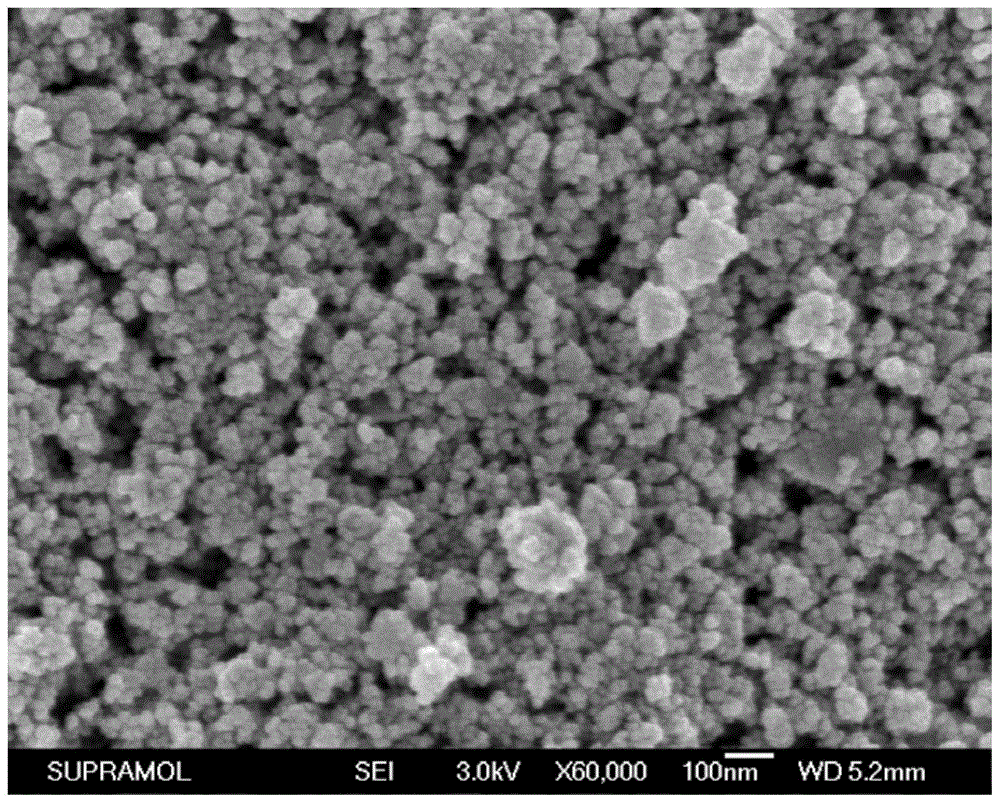

[0036] 50 mg of DBEDOT monomer and the sintered ATO porous membrane support layer 2 were put into a conical flask with a volume of 100 ml, and nitrogen gas was introduced as a protective gas, and then the conical flask was sealed. The entire system was heated at 70 degrees Celsius for 3 hours to obtain a PEDOT porous membrane, ...

Embodiment 2

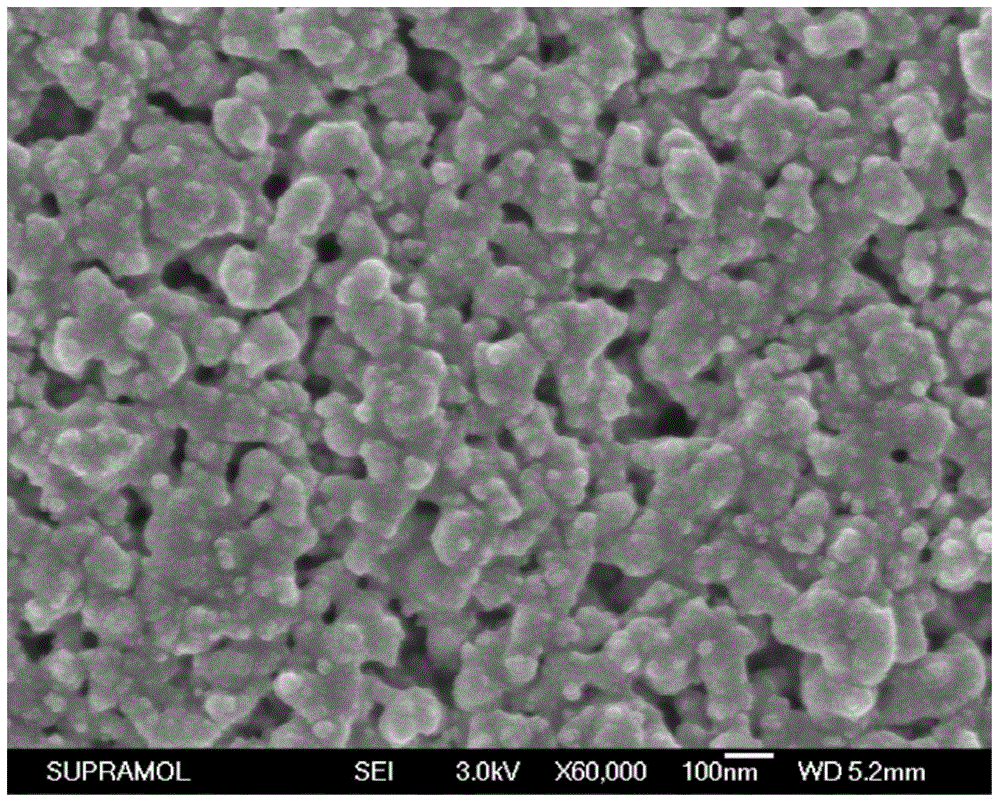

[0040] The composite PEDOT counter electrode is based on ITO conductive glass 1, and the mass ratio of ATO nano conductive powder, terpineol, ethyl cellulose, lauric acid and ethanol is 1:6:0.3:0.1:15 and mixed evenly to obtain ATO slurry. Take 100 microliters of ATO slurry, set the speed of the homogenizer to 2000 rpm, and last for 30 seconds to obtain an ATO film with a uniform thickness on the conductive glass substrate 1 . Subsequently, the prepared ATO membrane was sintered at a temperature of 500 degrees Celsius for 20 minutes to obtain an ATO porous membrane as the supporting layer 2 .

[0041] 100 mg of DBEDOT monomer and the sintered ATO porous membrane were put into a conical flask with a volume of 200 ml, and the conical flask was evacuated and sealed. The entire system is heated at 50 degrees Celsius for 24 hours to obtain a PEDOT porous membrane, which constitutes the conductive polymer membrane 3 . Finally, the composite PEDOT counter electrode was obtained. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com