Wire electrical discharge machining device and method

A technology of wire discharge machining and wire electrode, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., to achieve the effect of releasing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

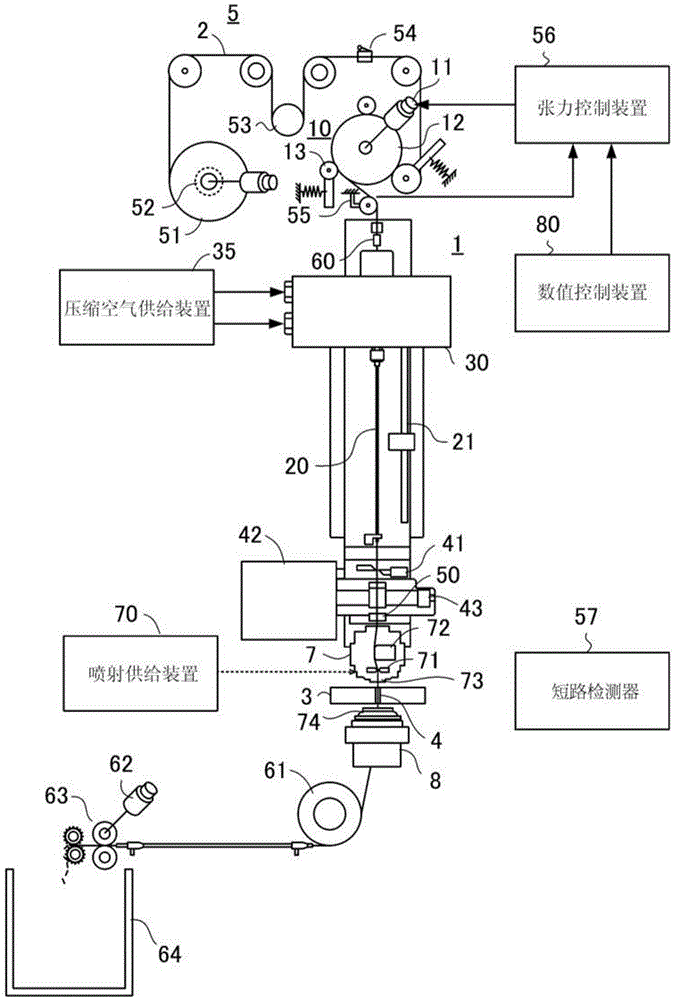

[0092] The wire electrical discharge machining apparatus of the present invention includes a short-circuit releasing system that reduces the tension of the wire electrode 2 and vibrates the wire electrode 2 to release the short circuit. figure 1 , represents the wire electric discharge machining device of the present invention. The supply mechanism 5 continuously supplies new wire electrodes 2 to the workpiece 3 . The supply mechanism 5 includes a reel 52 , a servo pulley 53 , a wire breakage detector 54 , a feed roller 10 , and a tension detector 55 . A wire bobbin 51 is mounted on a reel 52 . The reel 52 has a brake motor (brake motor) that applies reverse tension to the wire electrode 2 . The servo pulley 53 prevents fluctuations in tension. The wire breakage detector 54 is provided to detect breakage of the wire electrode 2 and is, for example, a limit switch.

[0093] The feed roller 10 includes a drive roller 12 and a pinch roller 13 . The drive roller 12 is rotated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com