Wire EDM

A wire electric discharge machine and electric discharge circuit technology, applied in electric machining equipment, metal machining equipment, circuits, etc., can solve the problems of longer machining time, recovery, and time spent on removing short circuits, so as to improve the accuracy of straightness, improve the Processing speed and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

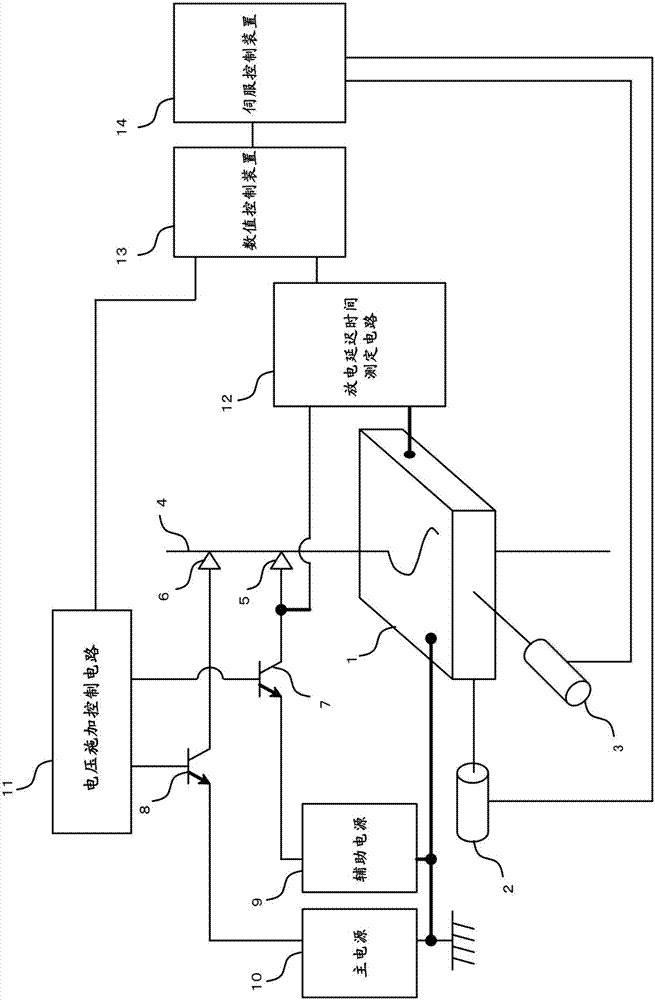

[0050] below, with Figure 1 Embodiments of the present invention will be described together. figure 1 It is a block diagram illustrating the wire electric discharge machine of the present invention. In the present invention, using the discharge delay time, the state between the poles is classified into a short circuit state, a situation with a small gap between the poles, and a situation with a large gap between the poles, and accordingly it is determined from the main discharge circuit (including the main power supply) 10. The magnitude of the machining current supplied by the circuit of the switching element 8).

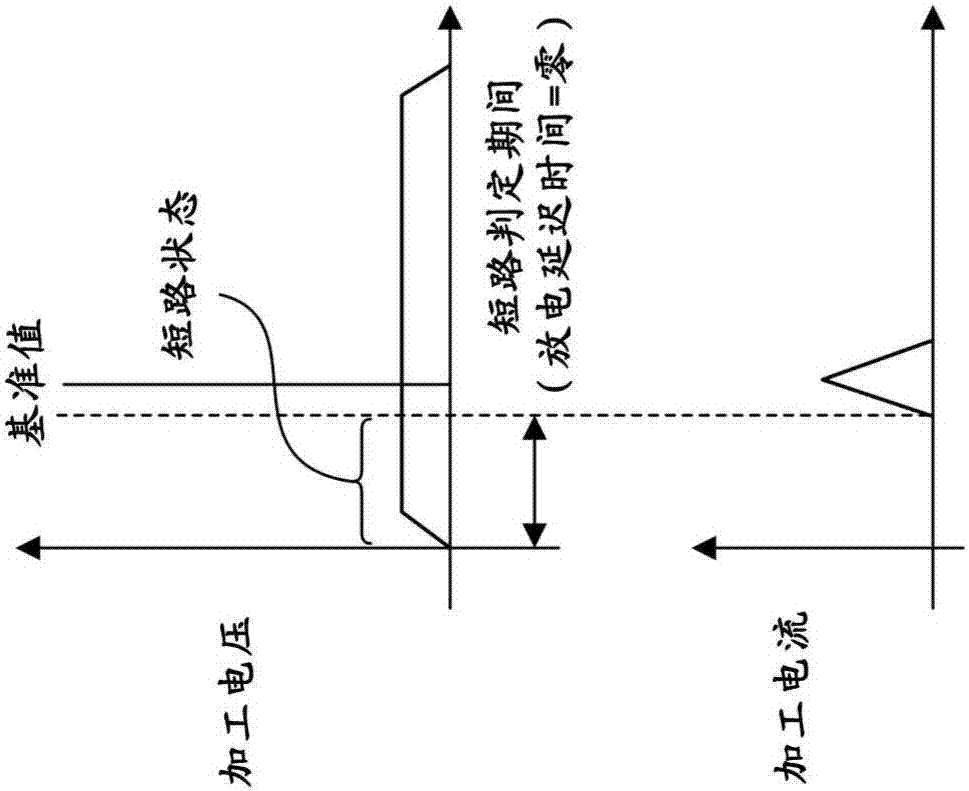

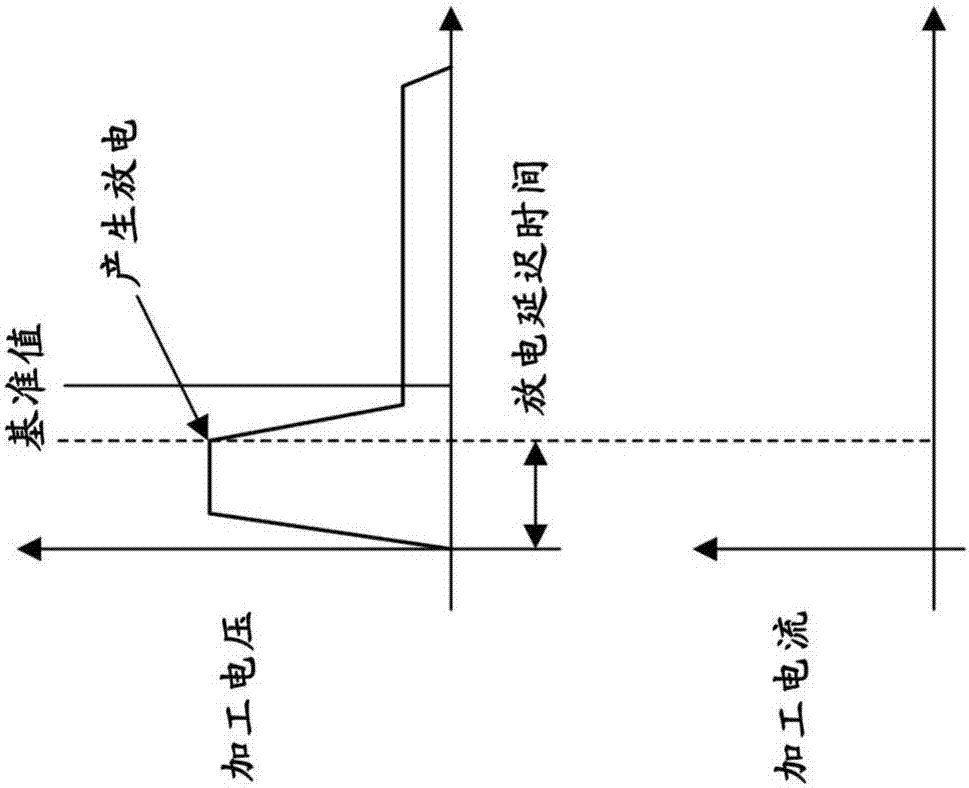

[0051] After a predetermined time has elapsed since the auxiliary discharge circuit (circuit including the auxiliary power supply 9 and the switching element) starts to apply the machining voltage to the inter-electrodes, in the case where the discharge delay time is zero (that is, in a state where there is no discharge), it is judged that Because the electrodes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com