Long-depth annular hole machining method

A processing method and technology for annular holes, which are used in metal processing equipment, manufacturing tools, drilling/drilling equipment, etc., to achieve high cutting efficiency, reduced processing time and cost, and good cutting stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

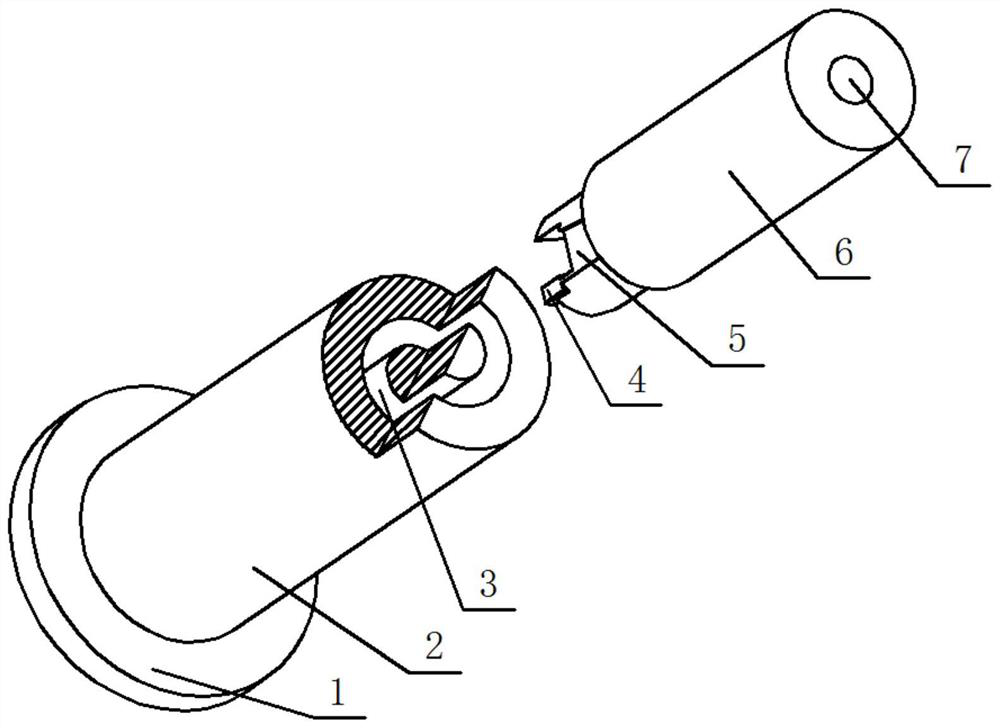

[0021] combined with figure 1 , the preferred embodiment of the present invention is described in detail as follows:

[0022] A long-depth annular hole machining method is realized based on a long-depth annular hole tool, the long-depth annular hole tool includes a cutter head 4 and a tool holder 6, and two grooves are arranged on one end of the cutter holder 6, and the cutter head 4 The shape matches the shape of the groove of the knife seat 6, the knife head 4 is placed on the groove of the knife seat 6, and a rectangular groove is arranged between the two knife heads 4; the center of the knife seat 6 is provided with a middle outlet hole 7, and the knife seat 6 is provided with two circumferentially symmetrical chip removal profiles, and an outward chip outlet 5 is provided at the bottom of each chip removal profile;

[0023] The method comprises the steps of:

[0024] 1 Install the long-depth annular hole tool into the tool magazine, and fix the part 2 on the workbench w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com