Forming method of composite conical shell with end frame

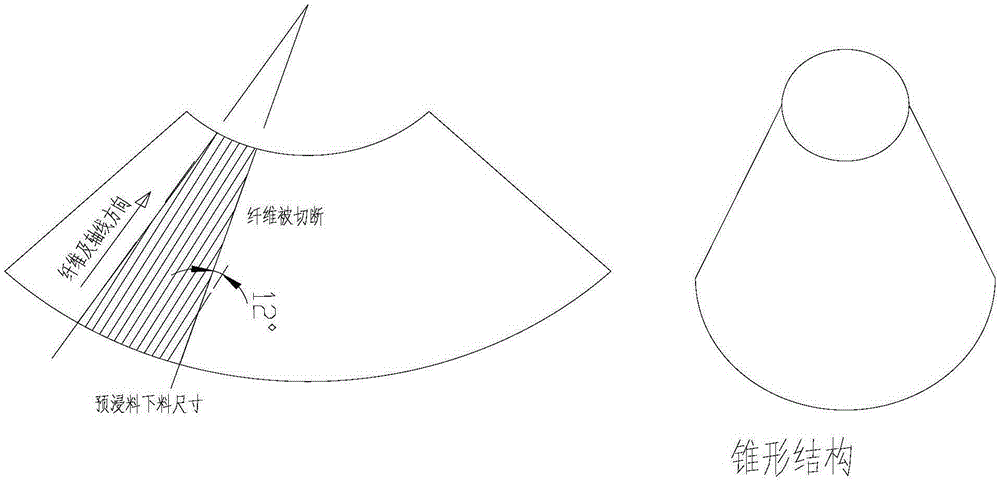

A composite material and strip-end technology, which is applied in the field of composite conical shell molding, can solve problems such as insufficient fiber strength, prepreg wrinkling, and fiber continuity damage, so as to optimize local mechanical properties and improve load bearing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

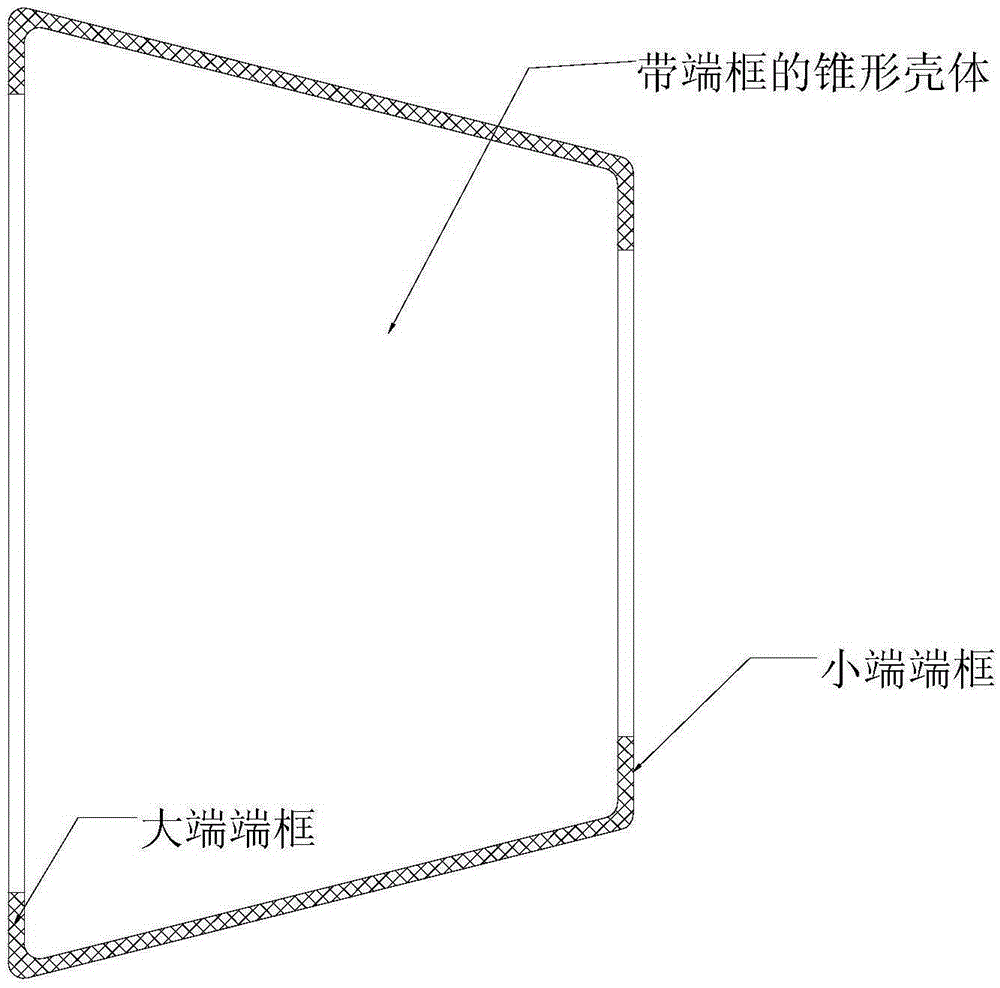

[0033] A composite conical shell with an end frame, the shell has an end frame turned 90° at the end of the shell, which are respectively a small end end frame and a large end end frame.

[0034] A method for preparing a composite conical shell with an end frame, the steps are:

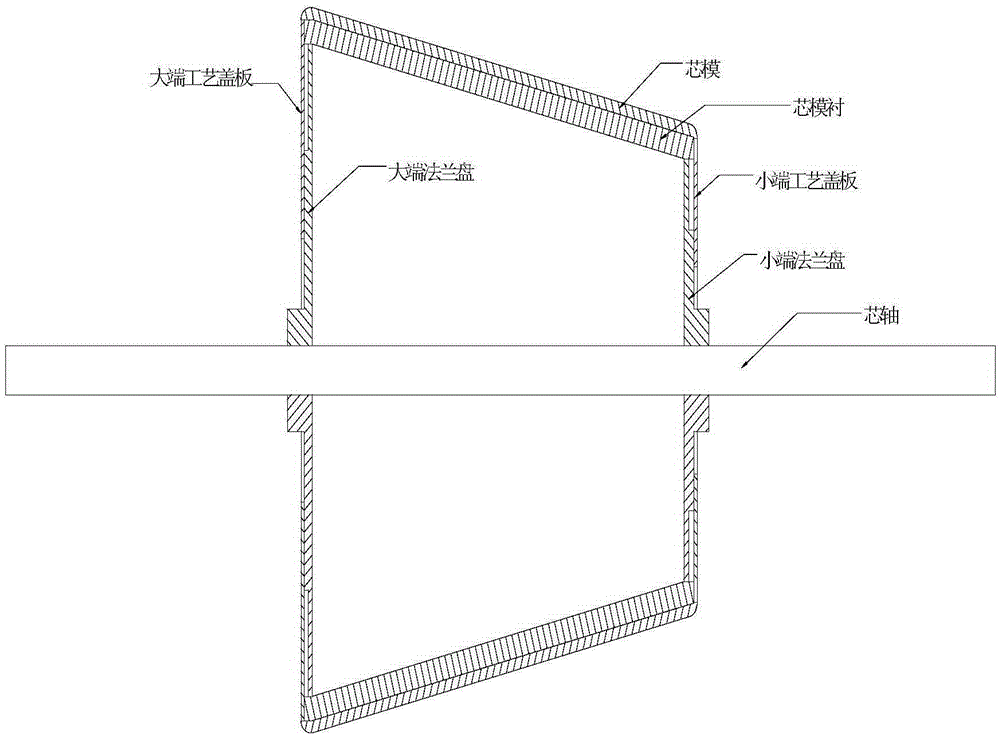

[0035] (1) The forming mold of the shell is prepared by the positive mold forming method: as figure 2 As shown, the mold is composed of a mandrel, a large end flange, a small end flange, a large end process cover plate, a small end process cover plate, a mandrel lining and a mandrel; wherein, the small end of the mandrel lining passes through the small end The end flange is fixed on the mandrel, the small end process cover plate is fixedly connected to the small end flange, and the mandrel is fixedly connected to the outside of the mandrel lining;

[0036] The big end of the mandrel lining is fixed on the mandrel through the big end flange, and the big end process cover plate is fixedly connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com