Straight moving style gear speed increasing (reducing) device

A technology of gears and gearboxes, which is applied in the field of "direct-acting gear speed increaser"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

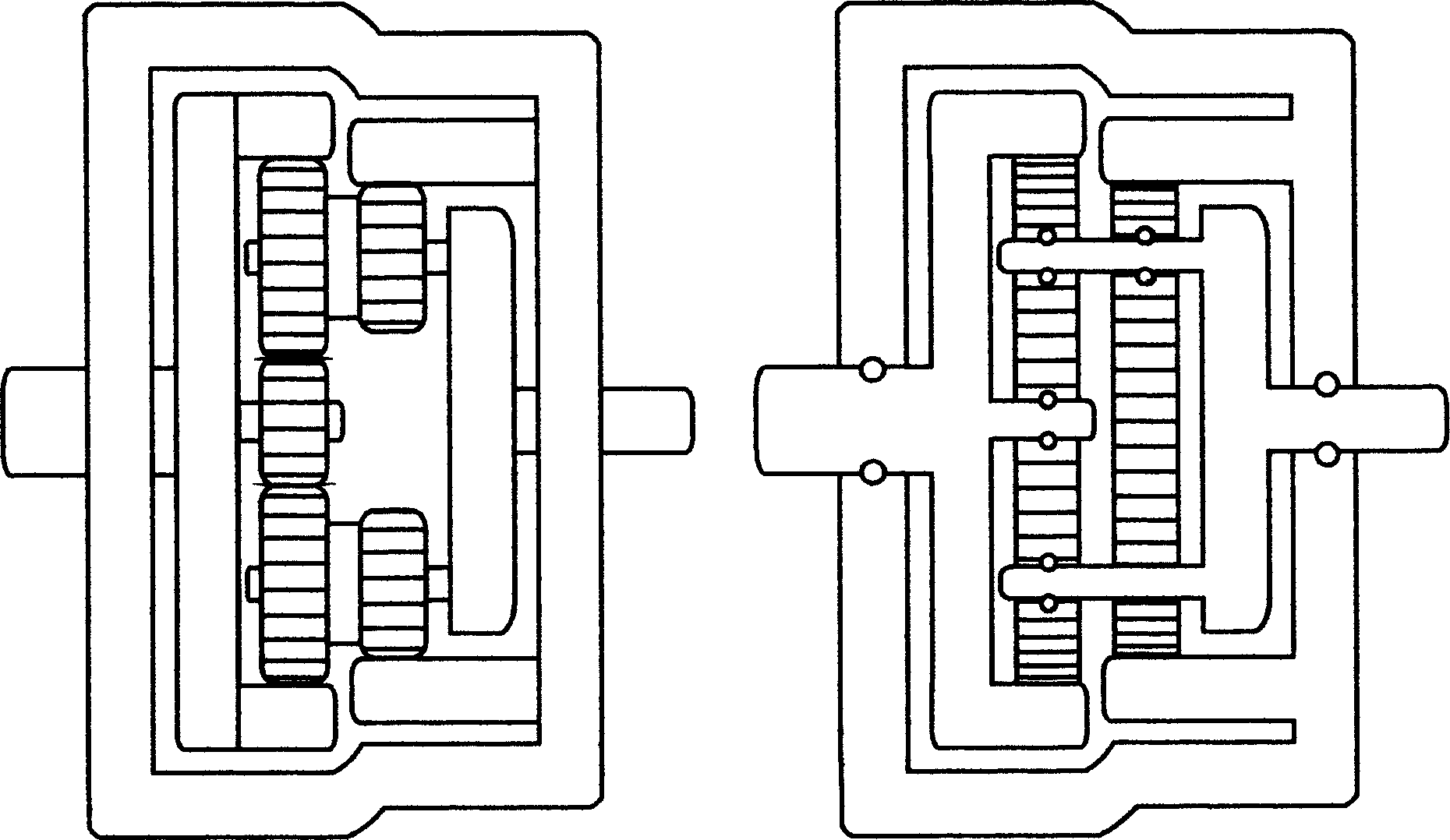

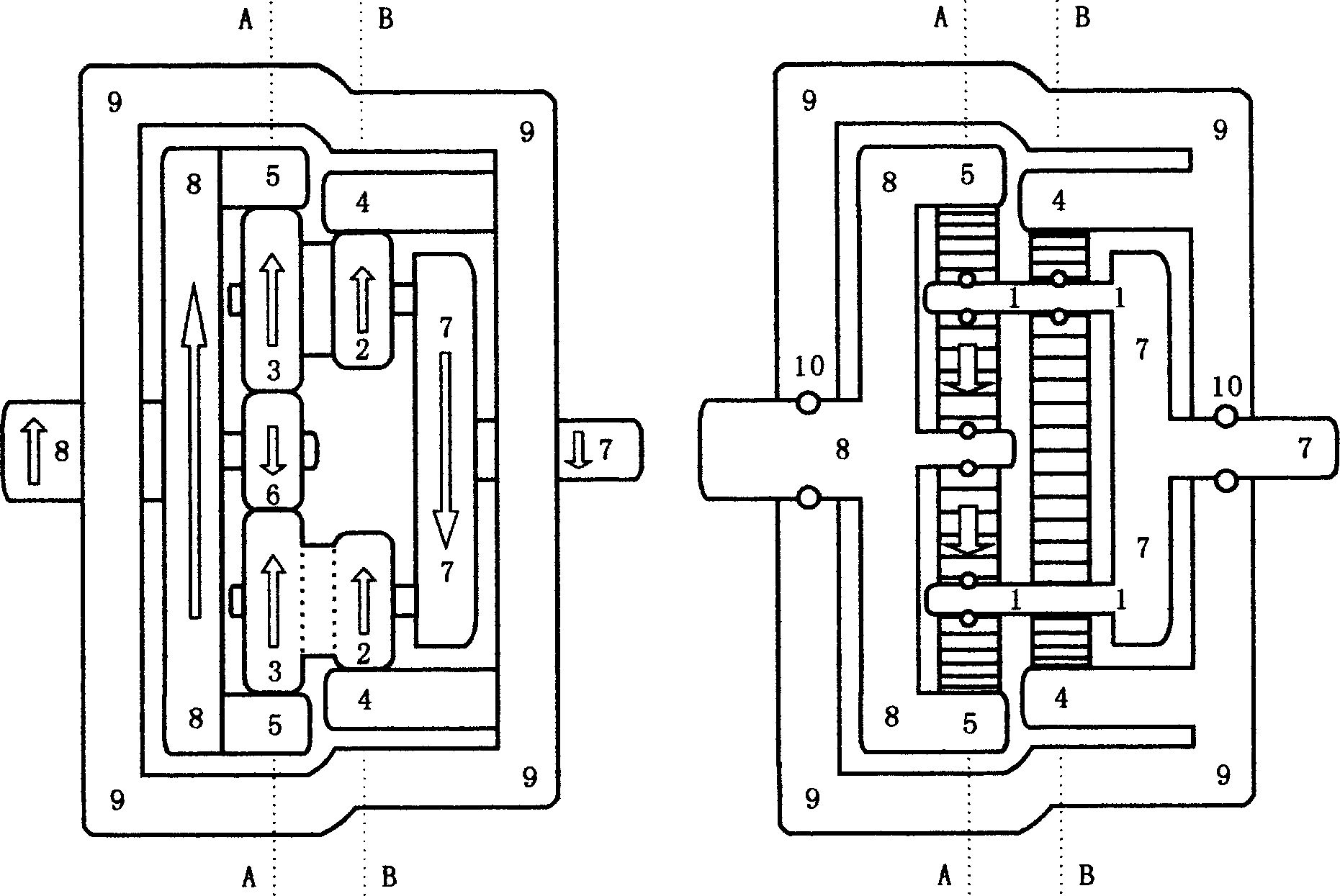

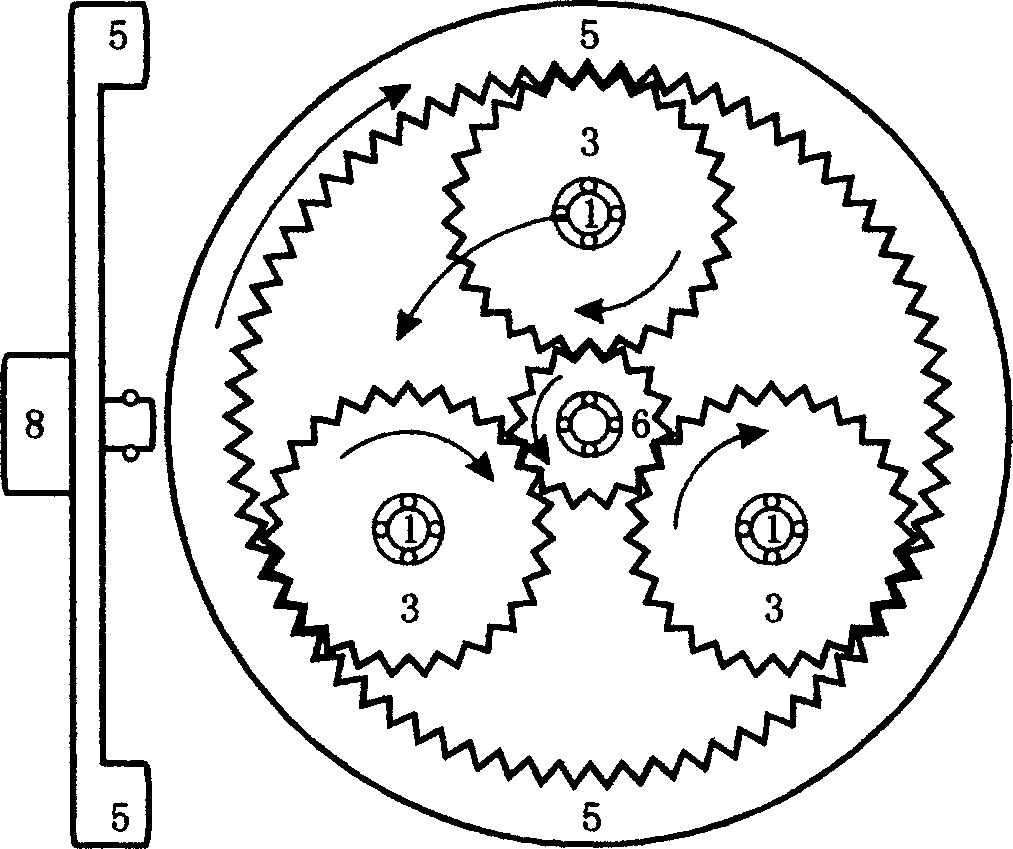

[0014] The present invention mainly includes housing 9, input shaft 7, output shaft 8 and related gears contained in housing 9, it is different from the prior art in that: input shaft 7 is fixedly connected with planetary gear shaft 1; 2 is fixedly connected with gear 3; gear 4 is fixedly connected with housing 9; output shaft 8 is fixedly connected with gear 5.

[0015] Gear 6 is installed on the extended part of the output shaft shaft center by bearing, and the place that output shaft and input shaft are connected with housing is all equipped with bearing, and planetary gear is fixed on the planetary gear shaft 1 by bearing.

[0016] Gear 2 meshes with internal gear 4; gear 3 meshes with internal gear 5, and gear 3 meshes with gear 6 at the same time.

[0017] ( Figure 5-1 ) The length from the center point of gear 2 to the meshing point with gear 4 is "active arm a", the meshing point of gear 2 and gear 4 is the "support point c" that bears gravity, and the part of gear 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com