A side frame trim component

A side frame and component technology, which is applied to vehicle components, transportation and packaging, etc., can solve the problems of affecting the normal use of side frame trim, unsightly appearance, troublesome assembly, etc., to achieve beautiful and coordinated appearance, increase the overall effect, and easy assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

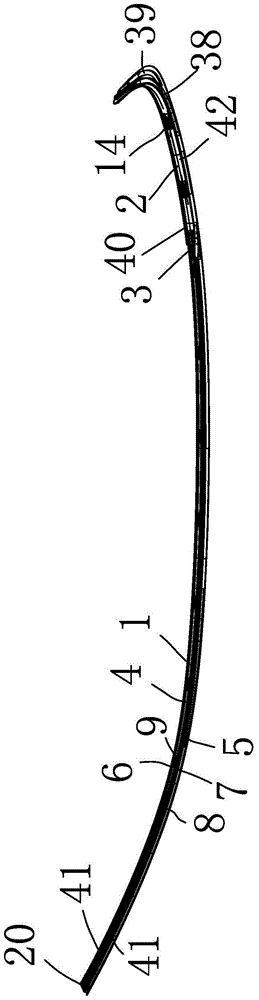

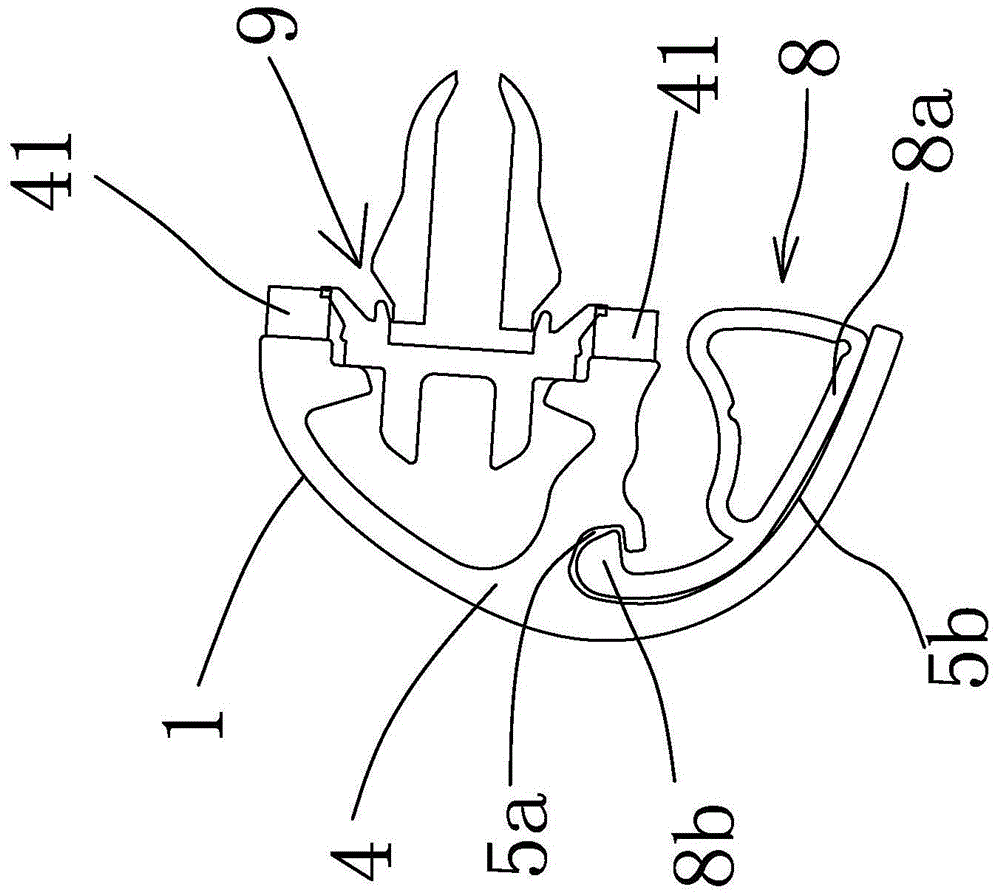

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0027] In the figure, upper bar body 1; frame body 2; connecting piece 3; assembly groove 4; door edge matching groove 5; inner groove part 5a; accommodation part 5b; Along the sealing strip 8; matching part 8a; curved groove part 8b; first buckle mechanism 9; first buckle base 10; first buckle head 11; first elastic foot 12; first stop step 13; Buckle mechanism 14; welding seat 15; second buckle base 16; second buckle head 17; second elastic foot 18; second blocking step 19; end cover 20; end cover 21; 22; pressing part 23; first platform block 24; second platform block 25; third platform block 26; fourth platform block 27; fifth platform block 28; sixth platform block 29; upper installation space 30; lower installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com