Amorphous alloy strip shear line

An amorphous alloy and production line technology, applied in the field of amorphous alloy strip shearing production line, can solve the problems of low magnetic permeability of transformer core and large no-load loss, and achieve the effects of saving cabinets, improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

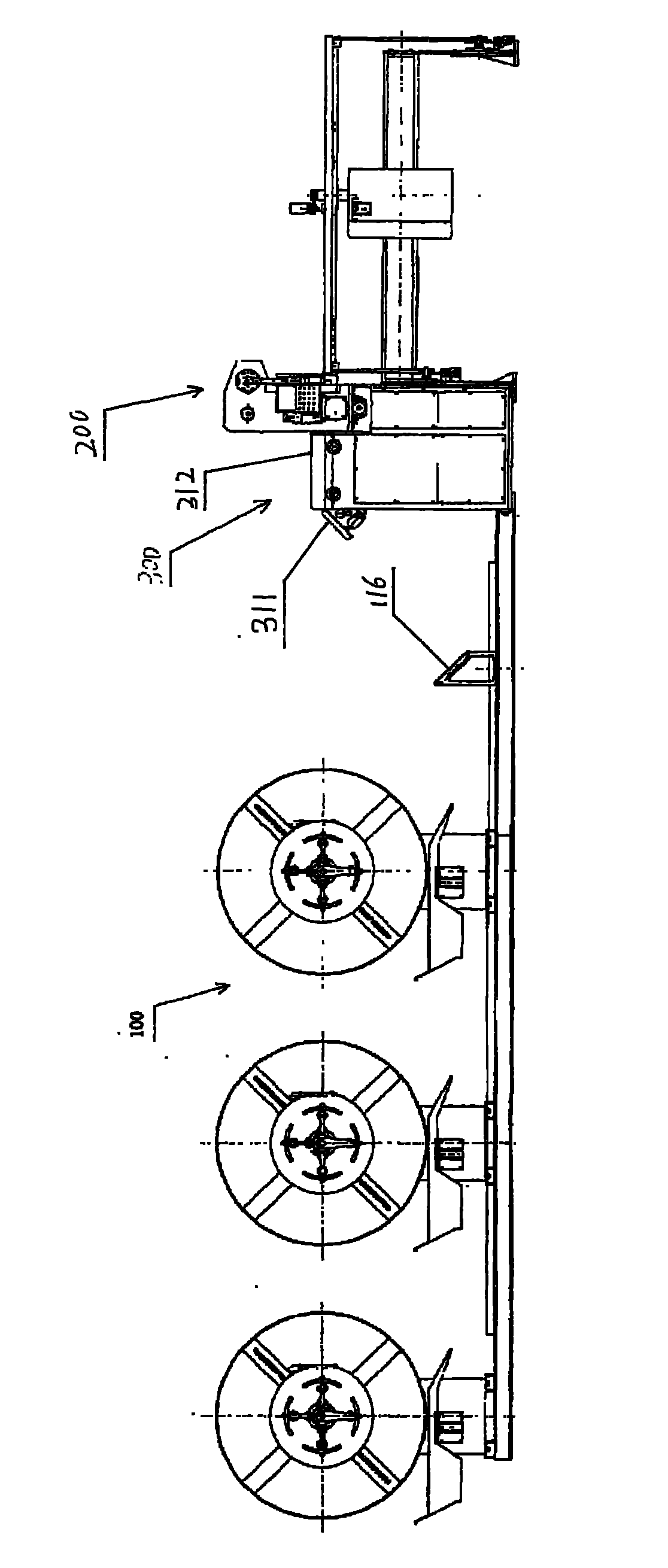

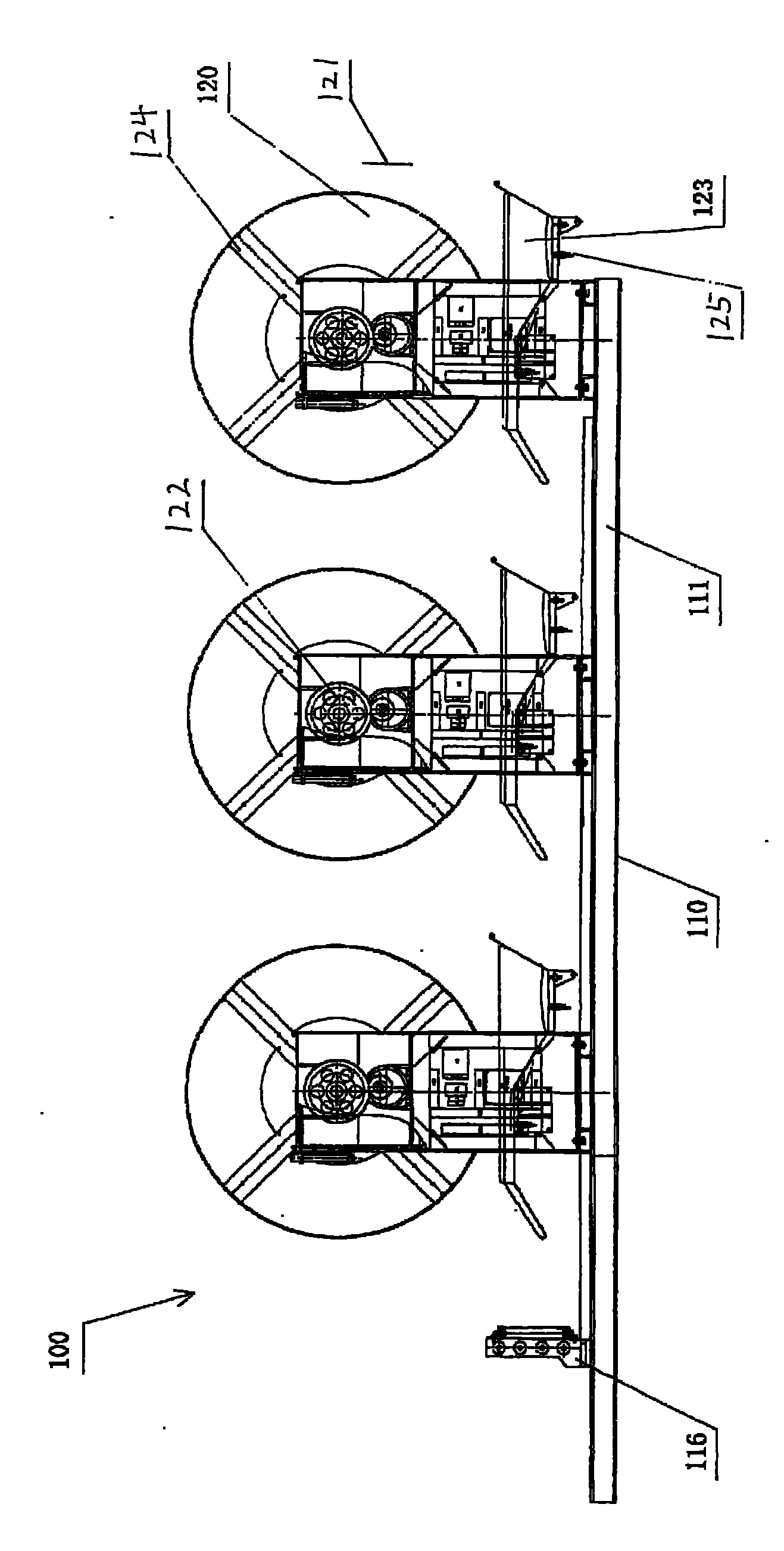

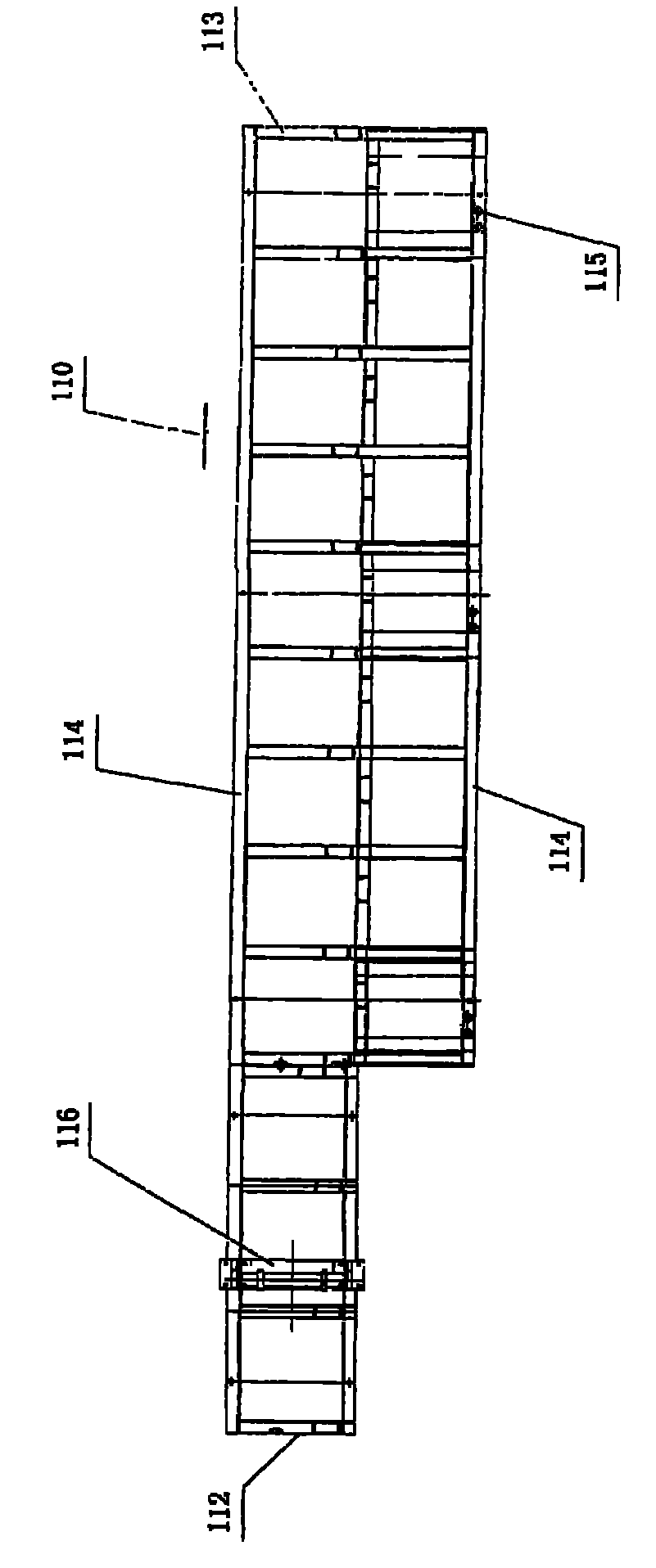

[0034] Such as Figure 1 to Figure 7As shown, the present invention provides a production line for shearing amorphous alloy strips, comprising sequentially arranged integral feeding devices 100 and sequentially distributed feeding devices 300 and numerically controlled amorphous steel strip shearing machines 200 on the frame, The numerically controlled amorphous steel strip shearing machine includes a programmable controller and a shearing host, and the programmable controller includes a programmable controller host 231 and a programming control panel, and the programmable controller host is located at the shear The cutting host is inside, and the programming control panel is set outside the cutting host.

[0035] The main shearing machine can include a frame 210 and a cutting head 250, the cutting head includes a housing 251, the housing is mounted on the frame by a detachable connection, and the programming control panel One side is hinged on the housing through a hinged bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com