Cable pay-off device

A technology of pay-off device and cable, applied in the directions of transportation and packaging, thin material handling, transportation of filamentous materials, etc., can solve the problems of high consumption, uneven force, damage to the lifting unit, etc., and prolong the service life. , The effect of reducing left and right shaking and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

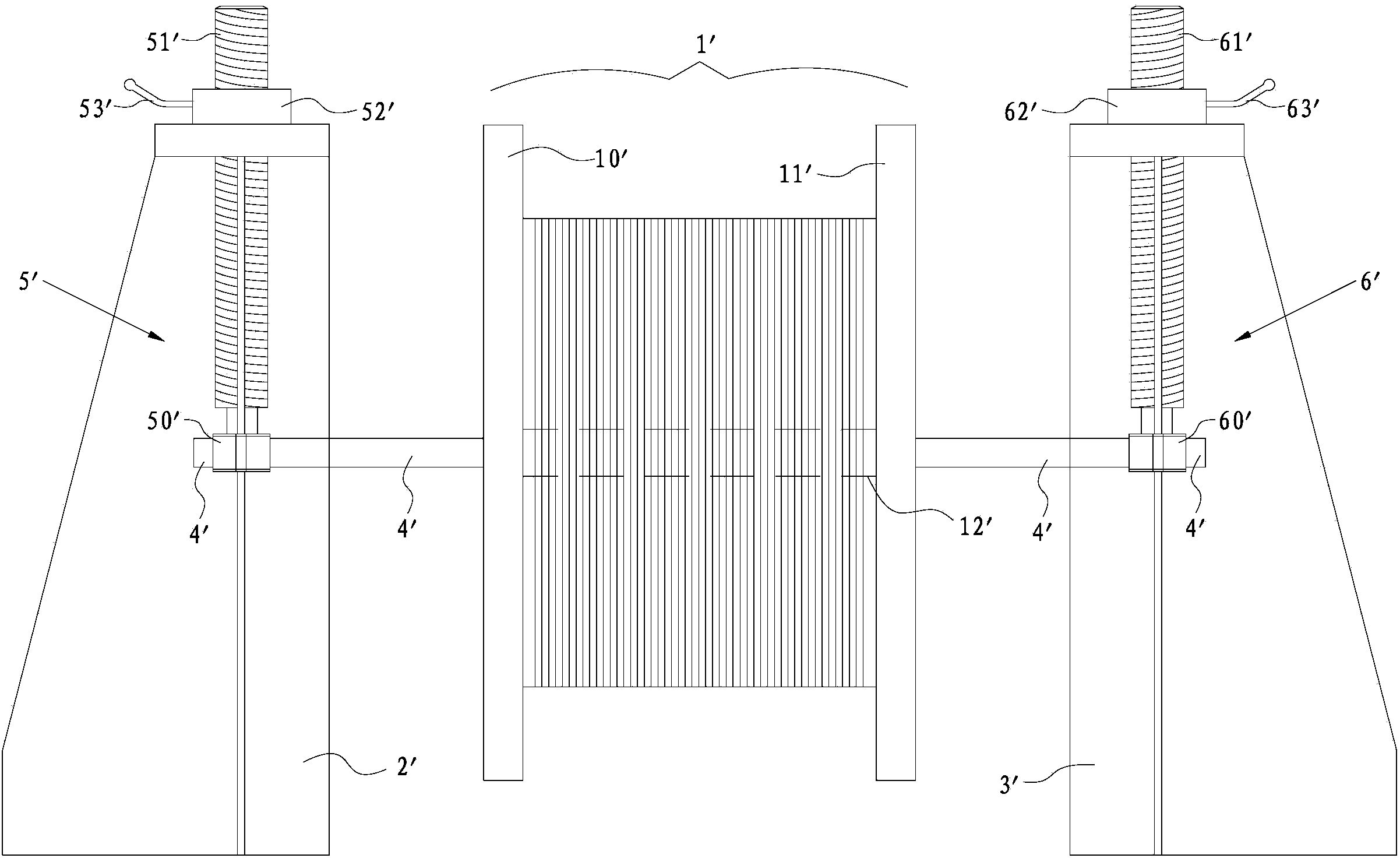

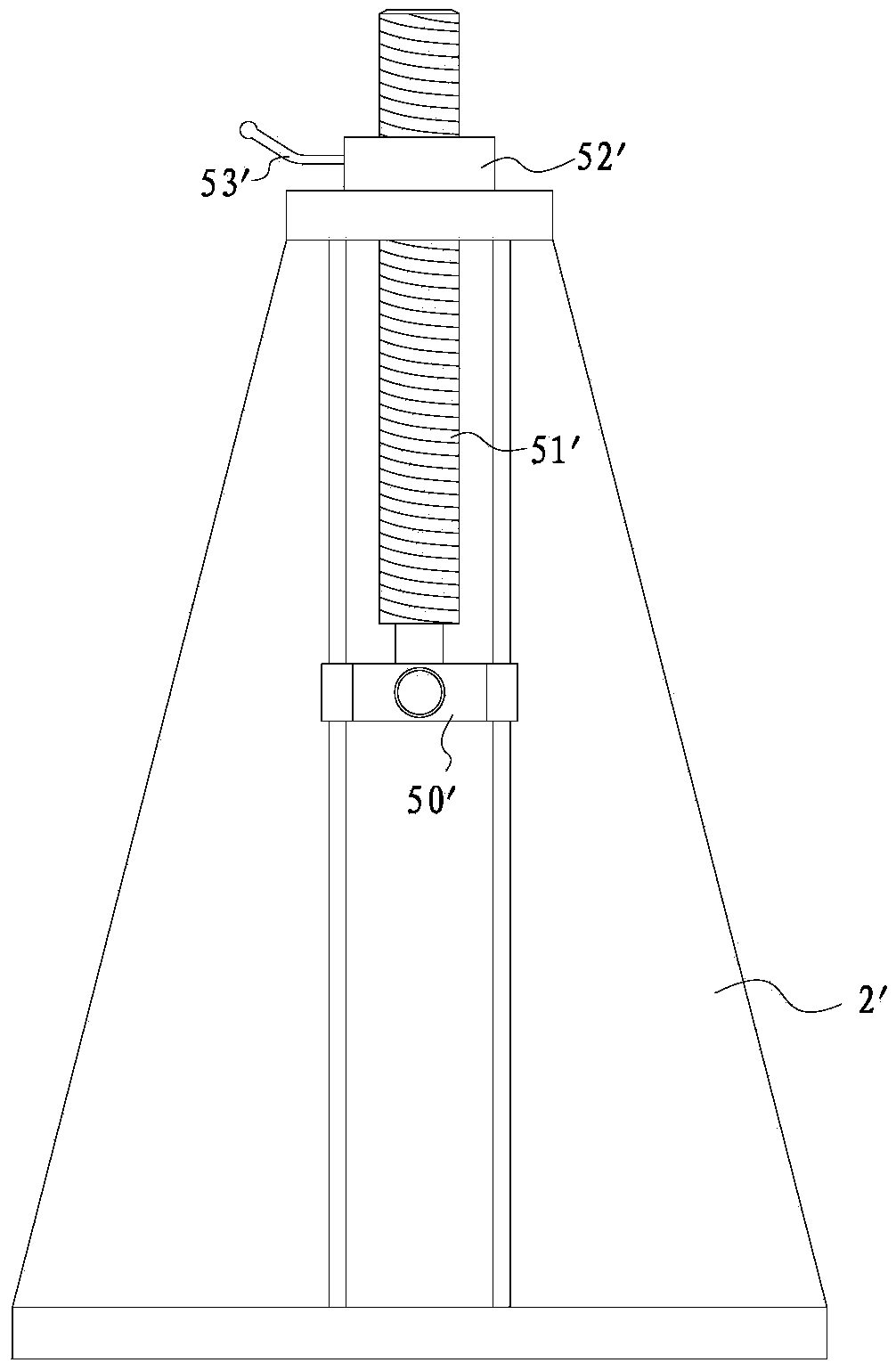

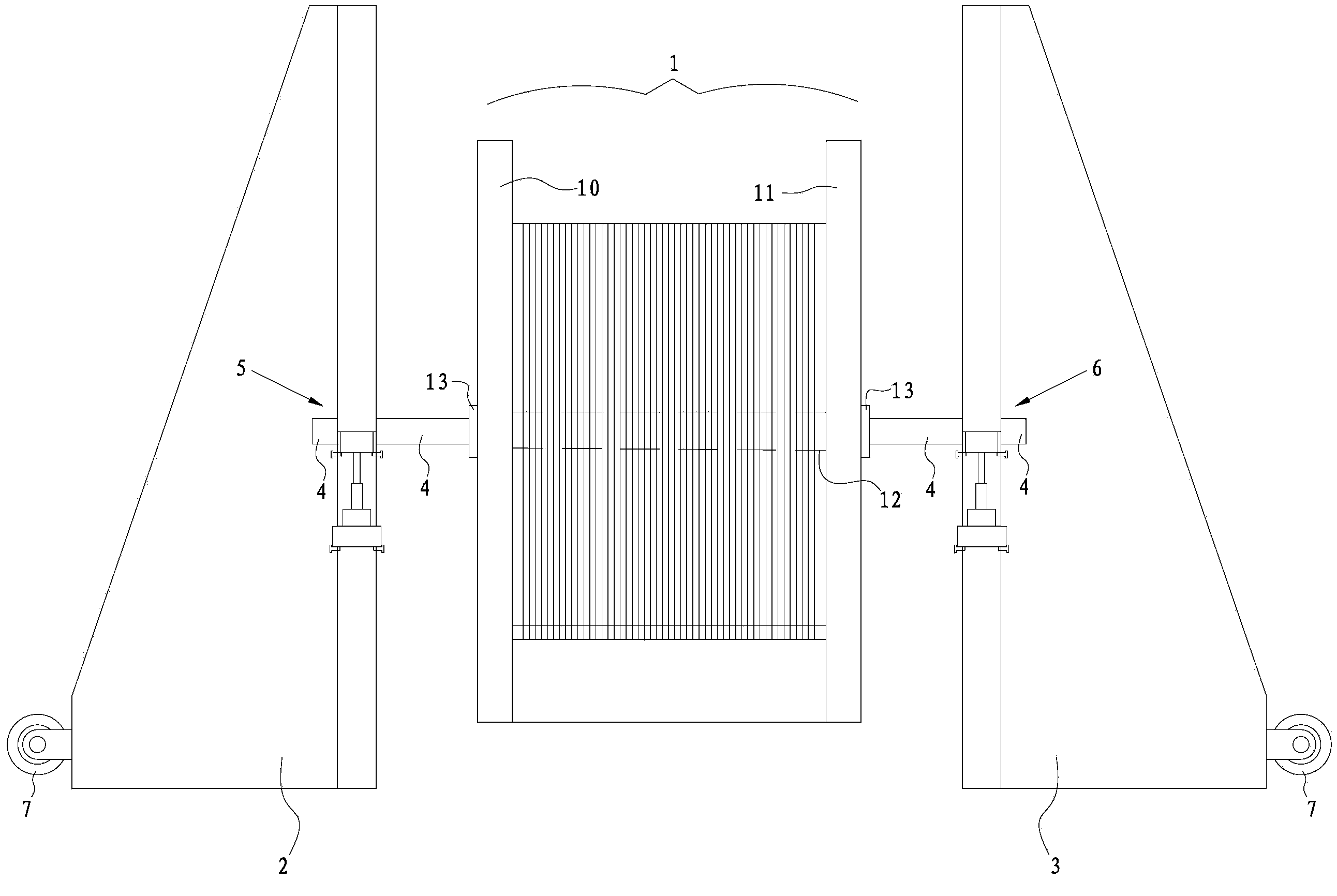

[0035] Such as Figure 3 to Figure 5 As shown, the pay-off device of the present embodiment mainly includes a left pay-off frame 2 and a right pay-off frame 3 located on the left and right sides of the reel 1, a reel shaft 12 crossing the reel 1, and two ends are respectively arranged on the left and right sides of the reel 1. The lifting rod 4 on the pay-off frame 2 and the right pay-off frame 3, and the left lifting unit 5 and Right lift unit 6.

[0036] Wherein the reel 1 comprises a reel 12, a left guardrail ring 10 and a right guardrail ring 11 positioned at both sides of the reel 12, the lifting bar 4 passes through the reel 12, and the reel is locked in the middle part of the lifting bar 4 by using the sleeve 13, so that the reel 12 The center line is collinear with the center line of the lifting bar 4, which effectively reduces the left and right shaking of the reel 1.

[0037] The left pay-off frame 2 and the right pay-off frame 3 are set symmetrically about t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com