A Corbelless Steel Anchor Beam

A technology of steel anchor beams and corbels, which is applied to bridges, bridge parts, bridge forms, etc., can solve the problems of limited application range, limited anchorage height and space of cable towers, and small vertical cable distance, etc., to improve the scope of application , Increase the proportion of horizontal component force, reduce the effect of steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

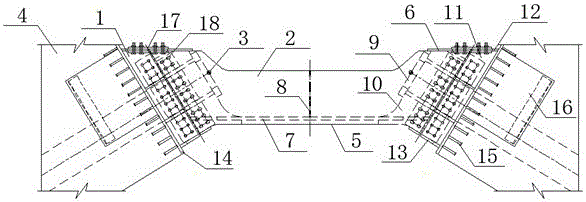

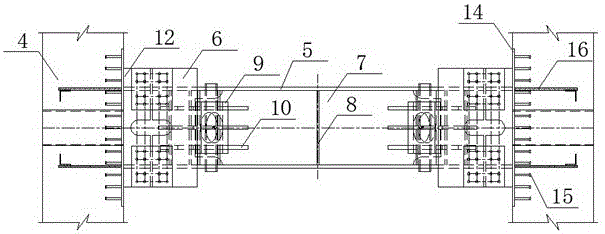

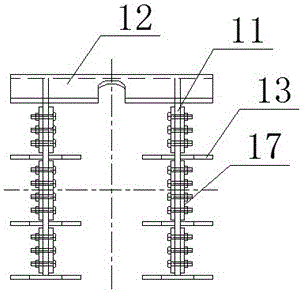

[0021] Below in conjunction with accompanying drawing, the present invention is further described: as Figure 1-3 As shown, a corbelless steel anchor beam includes an end support 1 , a middle balance beam 2 , and a stay cable anchor head 3 . End support 1 is composed of support web 11, support top plate 12, stiffening plate 13, wall plate 14 and its shear key. Wall 4 is connected. The middle balance beam 2 is an open box section, which is welded by steel plates such as the web 5 on both sides, the top plate 6 , the bottom plate 7 and the diaphragm 8 . The support web 11 and support top plate 12 of the end support 1 are respectively connected with the web 5 and top plate 6 of the middle balance beam 2 by connecting plates 17 and high-strength bolts. The bolt holes on the support web 11 of the end support 1 and the web 5 of the middle balance beam 2 are arranged in accordance with the direction of the stay cables, and the support web 11 of the end support 1 or the web 5 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com