Roadheader Cutting Section Hybrid Powertrain

A hybrid power and transmission system technology, applied in the field of transmission system, can solve the problems of poor vibration resistance of the transmission system, insufficient use of power, and high power of the cutting motor, so as to achieve strong ability to deal with faults, reduce power, and lighten load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

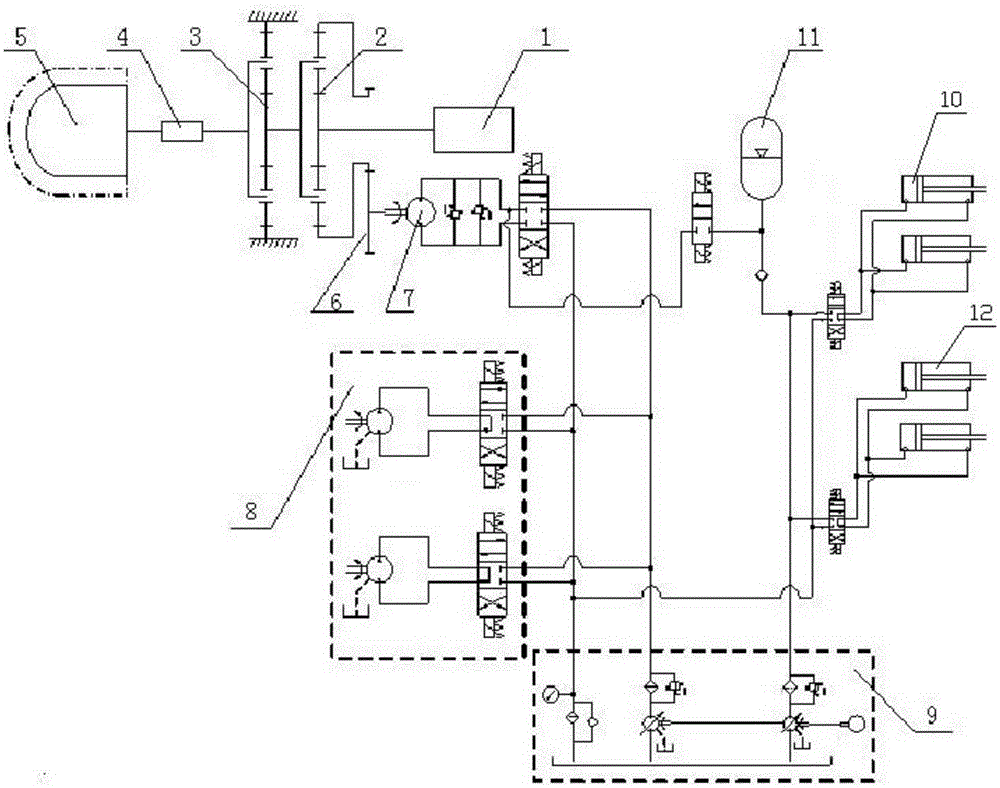

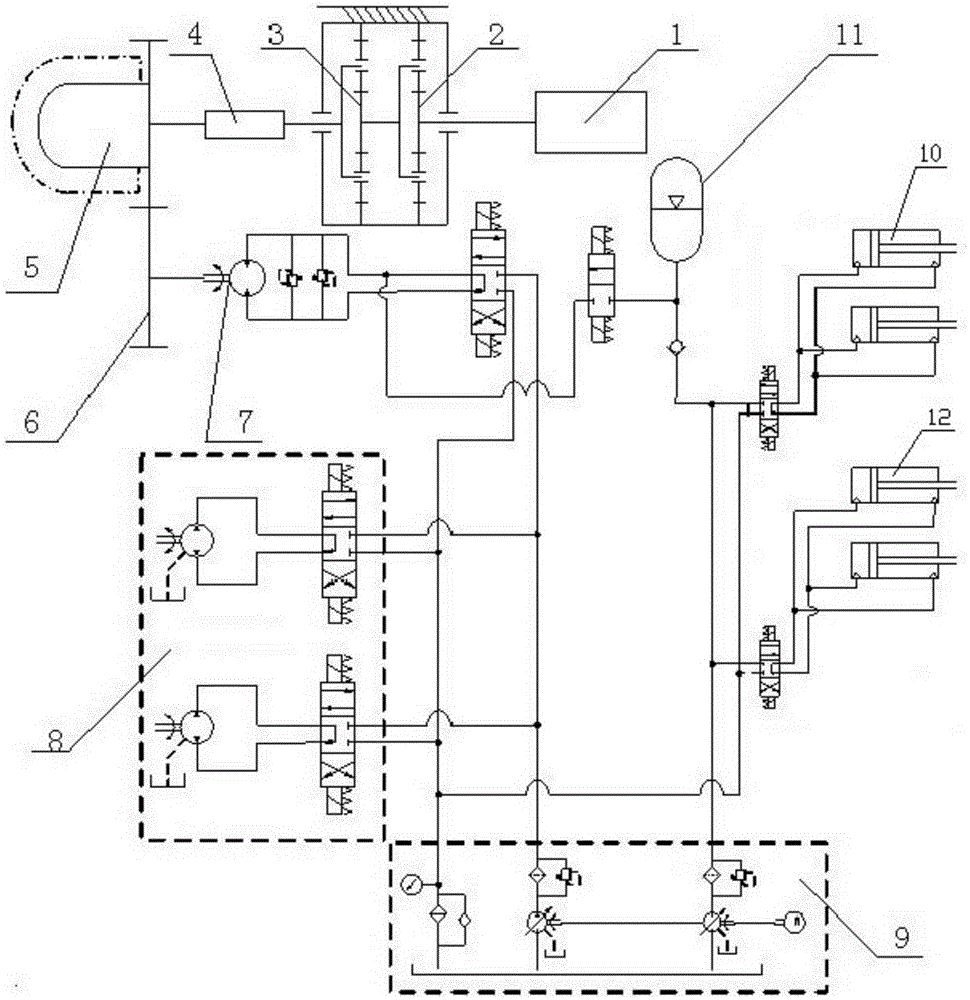

[0019] As shown in the figure, the hybrid power transmission system of the cutting part of the roadheader in this embodiment includes a cutting motor 1, a cutting head 5, a hydraulic motor 7 and a hydraulic power system 9 connected to the hydraulic motor 7. The hydraulic power system 9 It can be the original hydraulic power system of the roadheader. The cutting motor 1 and the cutting head 5 are connected through a planetary reducer, and the power end of the hydraulic motor 7 is connected with the planetary reducer through a gear pair. .

[0020] In this embodiment, the planetary reducer includes a first-stage planetary gear train 2 and a second-stage planetary gear train 3, and the sun gear of the first-stage planetary gear train 2 is coaxial with the power output end of the cutting motor 1 Fixedly connected, the planet carrier of the first-stage plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com