A device and method for testing material outgassing rate

A technology of outgassing and testing, applied in the direction of analyzing materials, instruments, etc., can solve problems such as oil return, and achieve the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

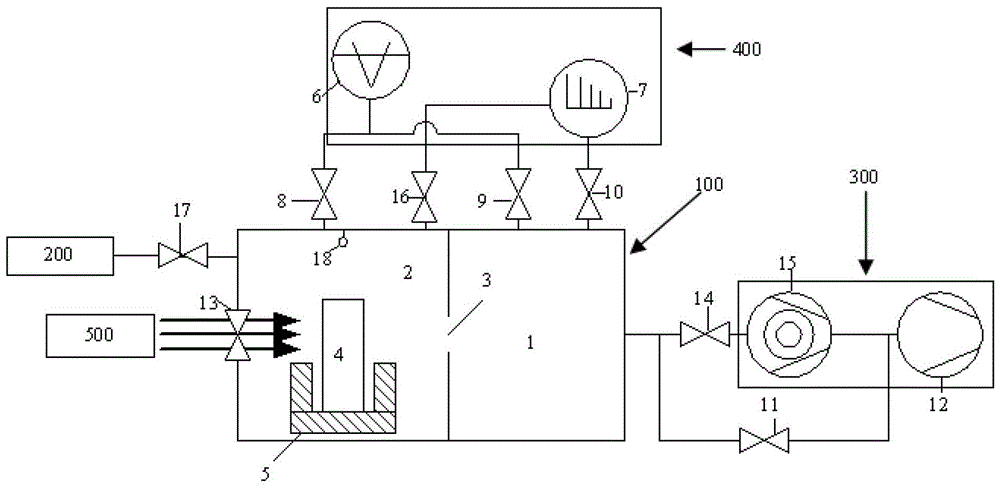

Image

Examples

Embodiment 1

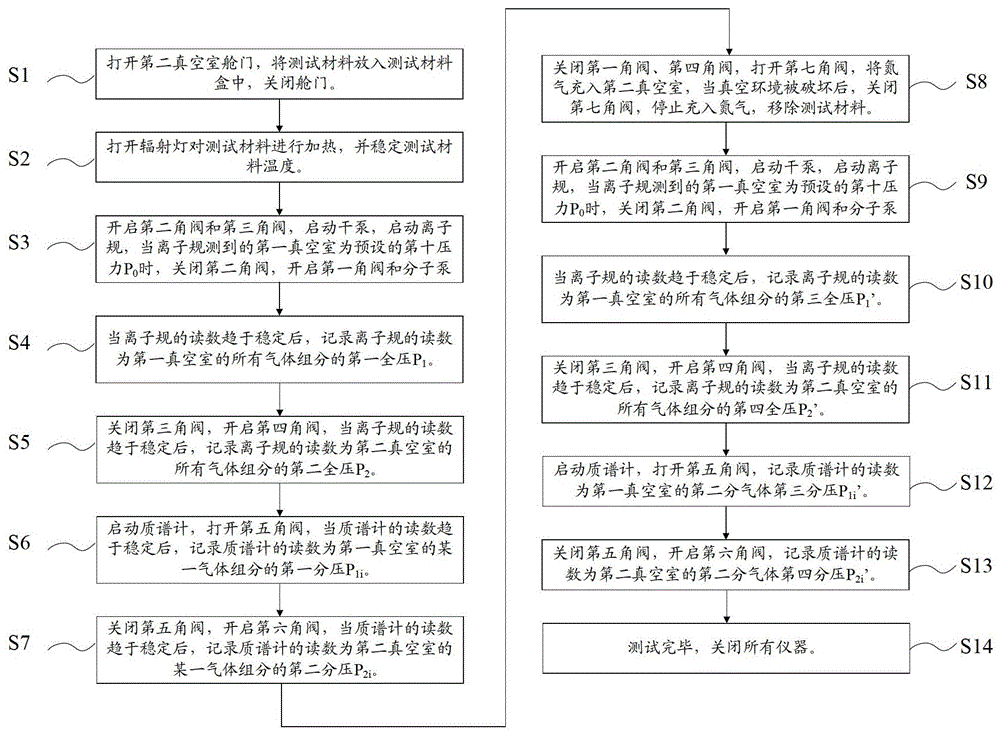

[0083] Such as figure 2 As shown, a method for testing the outgassing rate of the material, using the device for testing the outgassing rate of the material, the present embodiment can draw the total outgassing rate of all gas components released by the test material 4 and the release rate of the test material 4 The outgassing rate of a certain gas component.

[0084] A method of testing the outgassing rate of a material comprises:

[0085] S1: Open the hatch of the second vacuum chamber 2, put the test material 4 into the test material box 5, and close the hatch.

[0086] S2: turn on the radiation lamp 18 to heat the test material 4, and stabilize the temperature of the test material 4; because the outgassing rate of the test material 4 is related to the temperature, the temperature of the test material 4 is stabilized, which provides a basis for subsequent calculation of the outgassing rate of the test material 4 an exact temperature value.

[0087] S3: Open the second a...

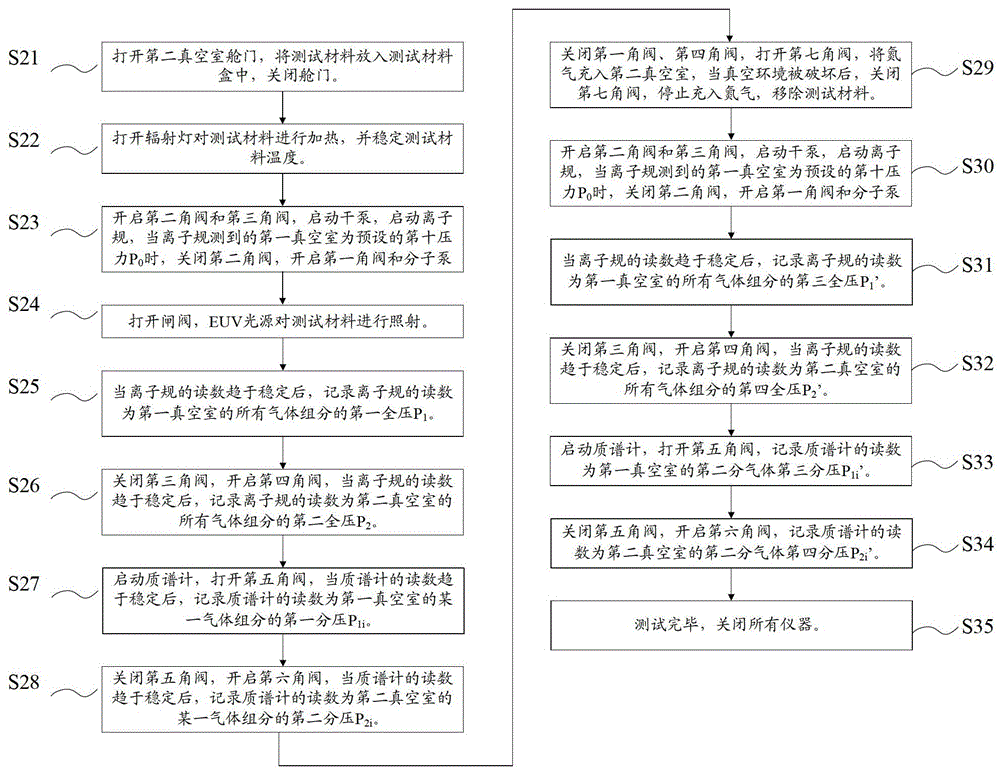

Embodiment 2

[0123] Such as image 3 As shown, on the basis of [Example 1], turn on the EUV light source to irradiate the sample, and study the outgassing rate of the test material 4 after being irradiated by the EUV light source.

[0124] A method of testing the outgassing rate of a material comprises:

[0125] S21: Open the hatch of the second vacuum chamber 2, put the test material 4 into the test material box 5, and close the hatch.

[0126] S22: turn on the radiation lamp 18 to heat the test material 4, and stabilize the temperature of the test material 4; because the outgassing rate of the test material 4 is related to the temperature, the temperature of the test material 4 is stabilized, which provides a basis for subsequent calculation of the outgassing rate of the test material 4 an exact temperature value.

[0127] S23: Open the second angle valve 11 and the third angle valve 9, start the dry pump 12, start the ion gauge 6, when the first vacuum chamber 1 measured by the ion ga...

Embodiment 3

[0143] Such as Figure 4 Shown is a method for testing the outgassing rate of materials. Using the device for testing the outgassing rate of materials, this embodiment can obtain the total outgassing rate of all gas components released by the test material 4 .

[0144] A method of testing the outgassing rate of a material comprises:

[0145] S41: Open the hatch of the second vacuum chamber 2, put the test material 4 into the test material box 5, and close the hatch.

[0146] S42: turn on the radiation lamp 18 to heat the test material 4, and stabilize the temperature of the test material 4; because the outgassing rate of the test material 4 is related to the temperature, the temperature of the test material 4 is stabilized, which provides for the subsequent calculation of the outgassing rate of the test material 4 an exact temperature value.

[0147] S43: Open the second angle valve 11 and the third angle valve 9, start the dry pump 12, start the ion gauge 6, when the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com