A Simplified Method for Finite Element Modeling of Honeycomb Sandwich Structure

A honeycomb sandwich and honeycomb structure technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of inability to accurately simplify the honeycomb sandwich structure, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method will be further described in detail through a finite element simplified modeling example of a honeycomb sandwich structure and in conjunction with the accompanying drawings.

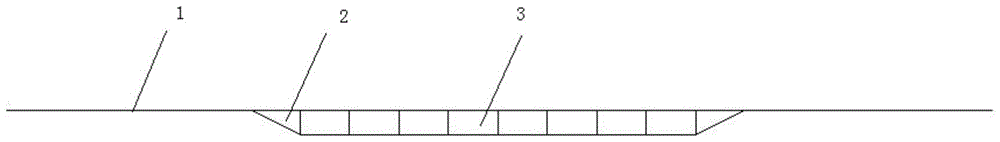

[0022] 1. For the specific form of honeycomb sandwich structure, its geometric parameter is that the thickness of the inner and outer skins is t 1 = t 2 =0.8mm, the height of the honeycomb is h=15mm, and the regions are divided according to the change of structural stiffness: edge region 1, transition region 2 and middle region 3.

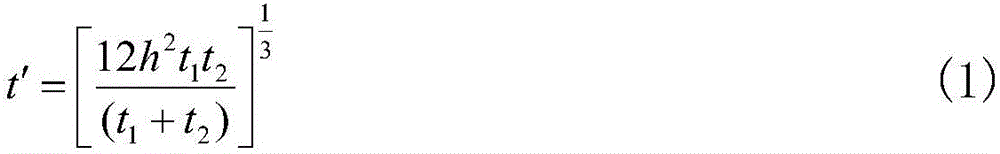

[0023] 2. According to the structural stiffness of different regions, the mechanical equivalent simplification is carried out:

[0024] In the element properties of the edge area, the in-plane stiffness and bending stiffness parameters are taken as the sum of the thickness of the inner and outer skins of the honeycomb structure, that is, 0.8+0.8=1.6mm;

[0025] In the element properties of the transition area, the in-plane stiffness parameter takes the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com