Edge scattering restraining method based on combined loading of microwave absorption foam and gradual change impedance strips

A composite loading and edge scattering technology, applied in electrical components, antennas, etc., can solve the problems of difficulty in application and lack of mechanical strength for loading, and achieve the effects of easy promotion, reduced edge scattering, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

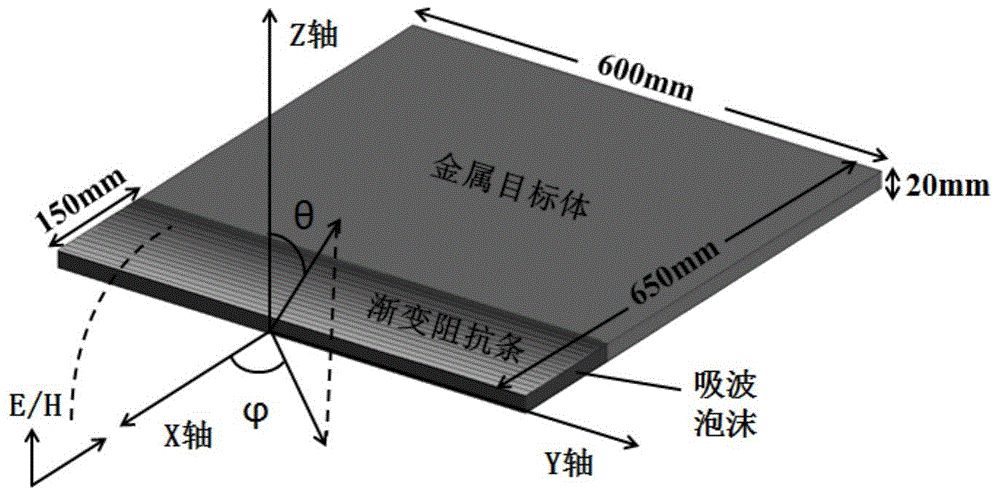

[0029] A rectangular metal plate with a length of 650 mm, a width of 600 mm, and a height of 20 mm is loaded with absorbing foam and gradient impedance strips.

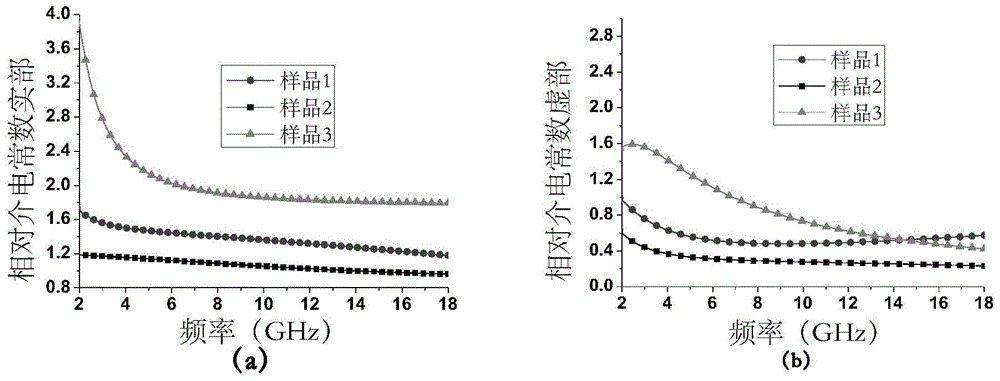

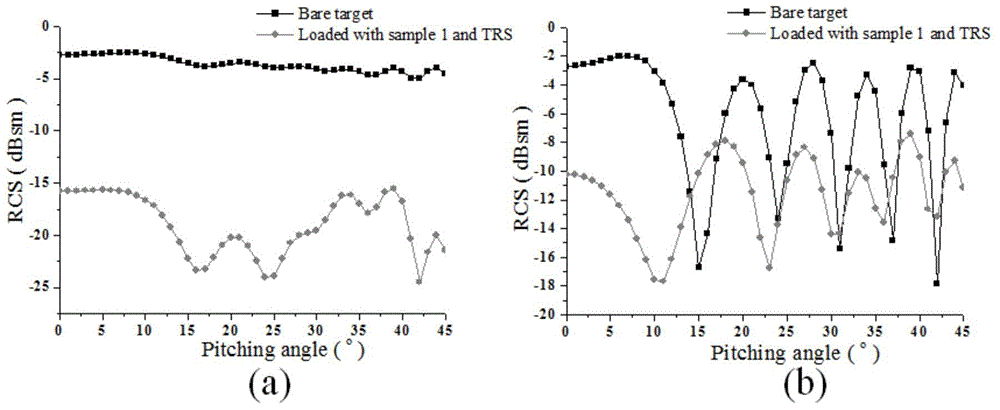

[0030] Set the incident wave frequency to 4GHz. The long axis of the rectangular metal plate is 150mm away from the front edge of the metal plate, and the metal target is cut off along the vertical direction of the long axis. Load absorbing foam as sample 1, and its relative permittivity is 1.1≤ε from 2GHz to 18GHz r '≤1.8, 0.4≤ε r ″≤1.0, to restore the original shape of the metal target. The upper and lower surfaces of the absorbing foam completely cover the gradient impedance strip, and the impedance change of the gradient impedance strip follows the linear change formula R(x)=k*x+b, where k= 6.45, b=-63.5, the gradient impedance bar is divided into 15 sections, and the values of x are 10, 30, 50, 70, 90, 110, 130, 150, 170, 190, 210, 230, 250, 270, 290. Among them, the impedance of the impedance strip at the c...

Embodiment 2

[0033] Load absorbing foam and gradient impedance strips on the elliptical cylindrical metal body with a major semi-axis of 400 mm, a minor semi-axis of 70 mm, and a height of 600 mm.

[0034] Set the frequency of the incident wave to 4 GHz, cut off the metal target along the vertical direction of the long axis at a distance of 150 mm from the front edge of the elliptical cylinder in the direction of the long axis of the ellipse. Load absorbing foam as sample 2, and its relative permittivity is 0.9≤ε from 2GHz to 18GHz r '≤1.2, 0.2≤ε r ″≤0.6, to restore the original shape of the target body. The upper and lower surfaces of the absorbing foam completely cover the gradient impedance strip, and the impedance change of the gradient impedance strip follows the exponential change formula R(x)=e a e b-x Among them, the amplitude factor a=0.05, the index factor b=0.06, the gradient impedance bar is divided into 15 sections, and the values of x are 5, 15, 25, 35, 45, 55, 65, 75, 85...

Embodiment 3

[0037] The metal target body formed by tangentially compounding the two waists of the isosceles triangular prism and the cylinder is loaded with absorbing foam and gradient impedance strips. The bottom surface of the triangular prism is an isosceles triangle with a vertex angle of 33.8°, a side length of 583 mm, and a height of 450 mm. The cylinder has a radius of 180mm and a height of 450mm.

[0038] Set the frequency of the incident wave to 4 GHz, cut off the metal target along the vertical direction of the long axis at a distance of 150 mm from the front edge of the metal target in the direction of the long axis of the metal target. Load absorbing foam as sample 3, and the relative permittivity is 1.8≤ε from 2GHz to 18GHz r '≤4.0, 0.4≤ε r ″≤1.6, to restore the original shape of the target body. The upper and lower surfaces of the absorbing foam completely cover the gradient impedance strip, and the impedance change of the gradient impedance strip follows the exponential c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com