Automatic compensation device for X-ray detection of weld joint of fuel rod end plug

An automatic compensation and fuel rod technology, which is applied in the field of ray detection, can solve problems such as the inability to ensure consistent distances between ray components, the inability to automatically determine the best transillumination area, and the inability to ensure transillumination welds, etc., to achieve automatic detection and avoid scratches. The effect of scratching the surface and improving the sensitivity of transillumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

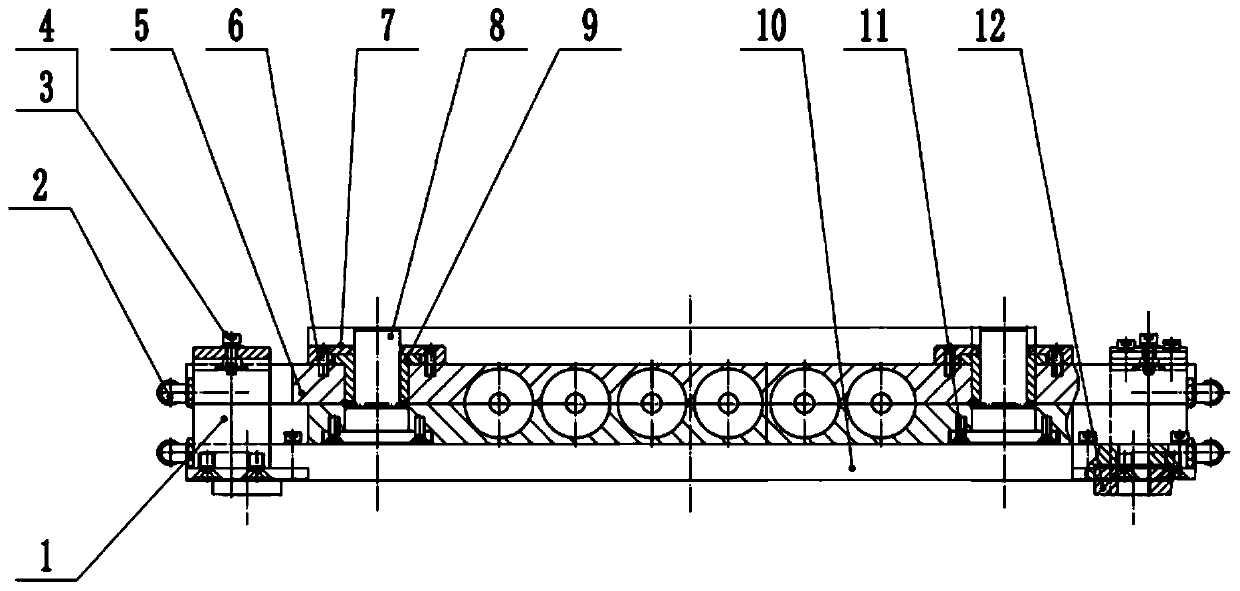

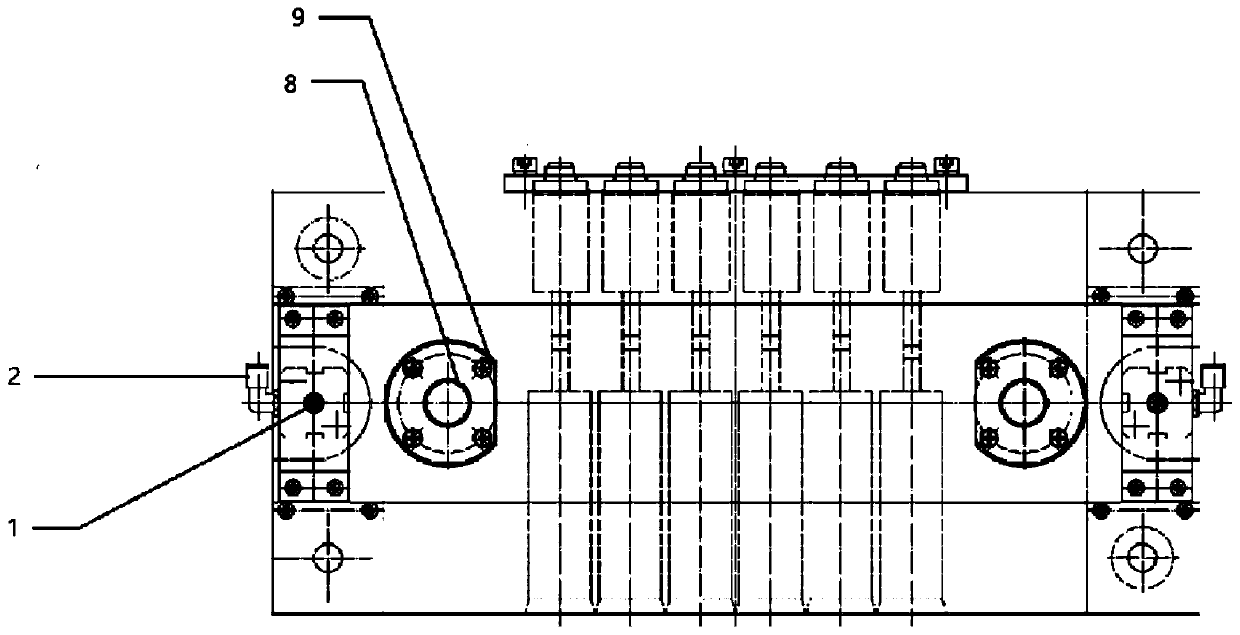

[0047] Such as Figure 1~3 The shown automatic compensation device for X-ray detection of fuel rod end plug welds includes an upper compensation block 5, a lower compensation block 10 and auxiliary components of the compensation block.

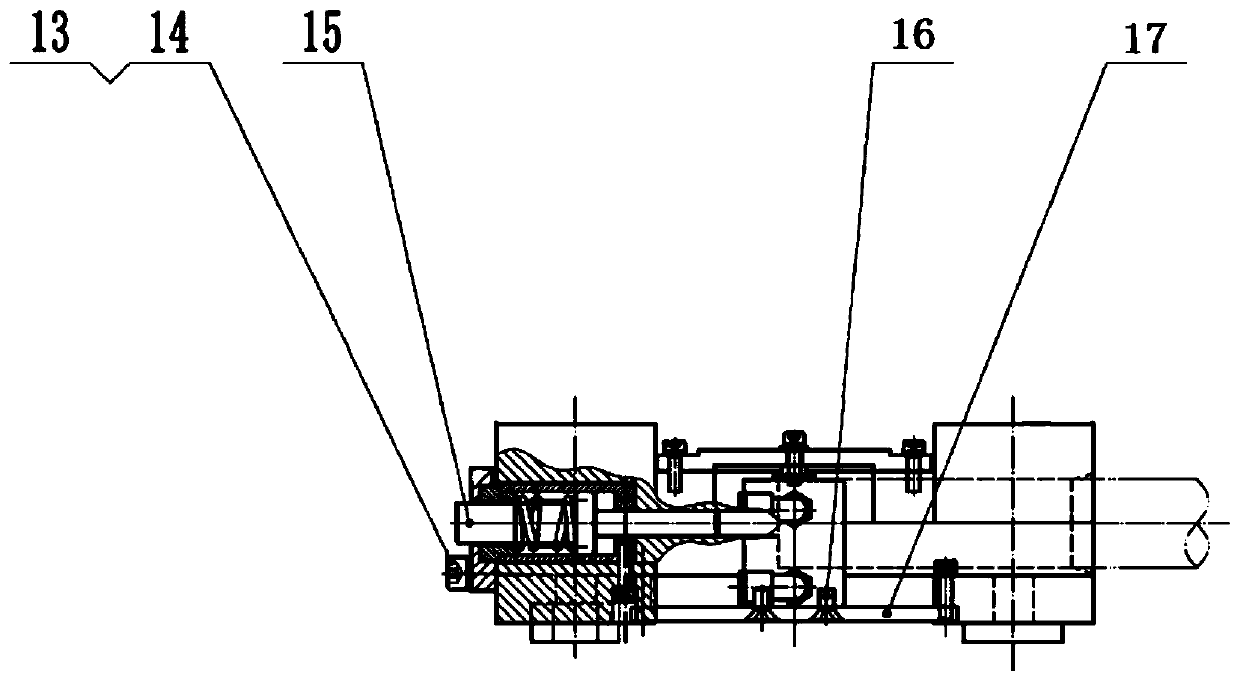

[0048] Such as Figure 4 As shown, the upper compensation block 5 is a rectangular plate with a length of 350 mm and a width of 80 mm, and its thickness is greater than the radius of the weld seam of the fuel rod end plug to be detected.

[0049] Two groups of threaded holes are processed on the left and right sides of the upper compensation block 5 . A plurality of compensation grooves are processed at equal intervals on the lower surface of the upper compensation block 5 , and the centerlines of each compensation groove are parallel to each other. The compensation groove is a semicircular groove,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com