A method for making gain medium for high-energy solid-state dye laser

A dye laser and gain medium technology, which is applied in the gain medium field of high-energy solid dye lasers, can solve the problems of shortening the lifespan of solid dyes, reducing lifespan, and insufficient light-receiving area of solid dyes, and achieving ideal beam quality and conversion efficiency, high effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

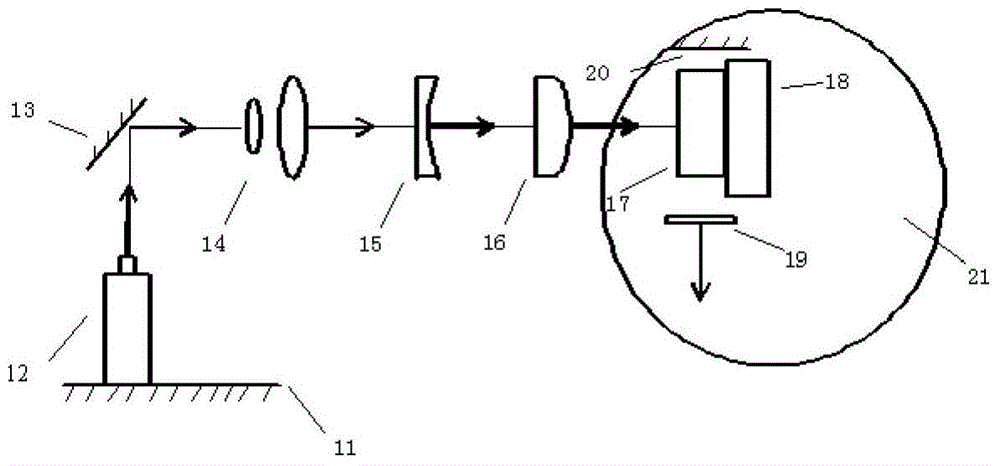

[0035] Such as figure 1 As shown, the present embodiment includes a launch stand 11, a laser pump source 12 fixed on the bottom of the launch stand 11, a 45° total reflection mirror 13, a beam expander 14, a plano-concave cylindrical mirror 15, and a plano-convex cylindrical mirror 16. Gain medium 17, refrigeration device 18, output mirror 19, total reflection mirror 20, rotating disk 21. The laser pumping source 12 is a pulsed laser with a wavelength of 532nm and a beam diameter of about 2mm. The beam expander 14 is a quadruple beam expander in the 532nm band, and the beam diameter becomes 8mm after the beam passes through it.

[0036] The plano-concave cylindrical mirror 15 is made of K9 material coated in the 532nm band, with a focal length of -19mm, a width of 19mm, a length of 38mm, a central thickness of 2mm, and a back focal length of -20.32mm. The plano-convex cylindrical lens 16 is made of K9 material coated in the 532nm band, and has a focal length of 75.6mm, a wid...

Embodiment 2

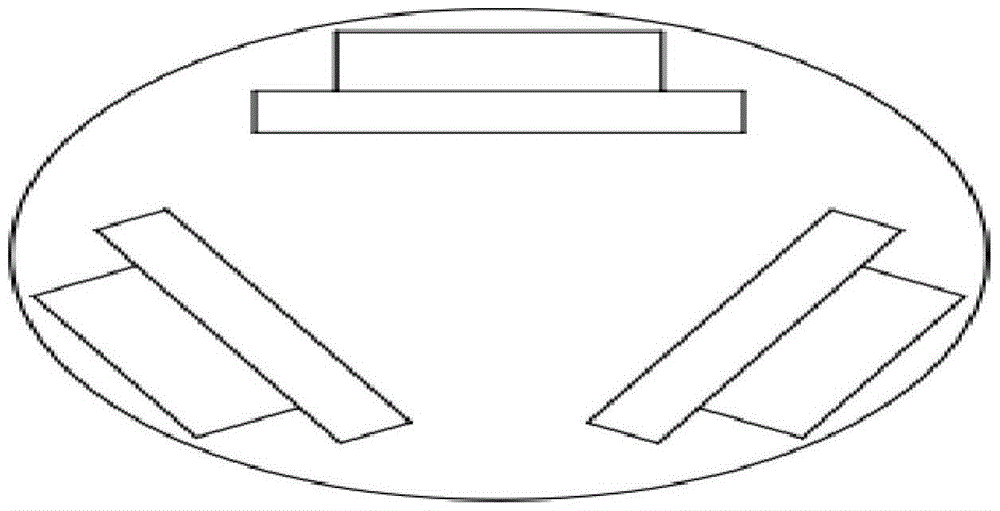

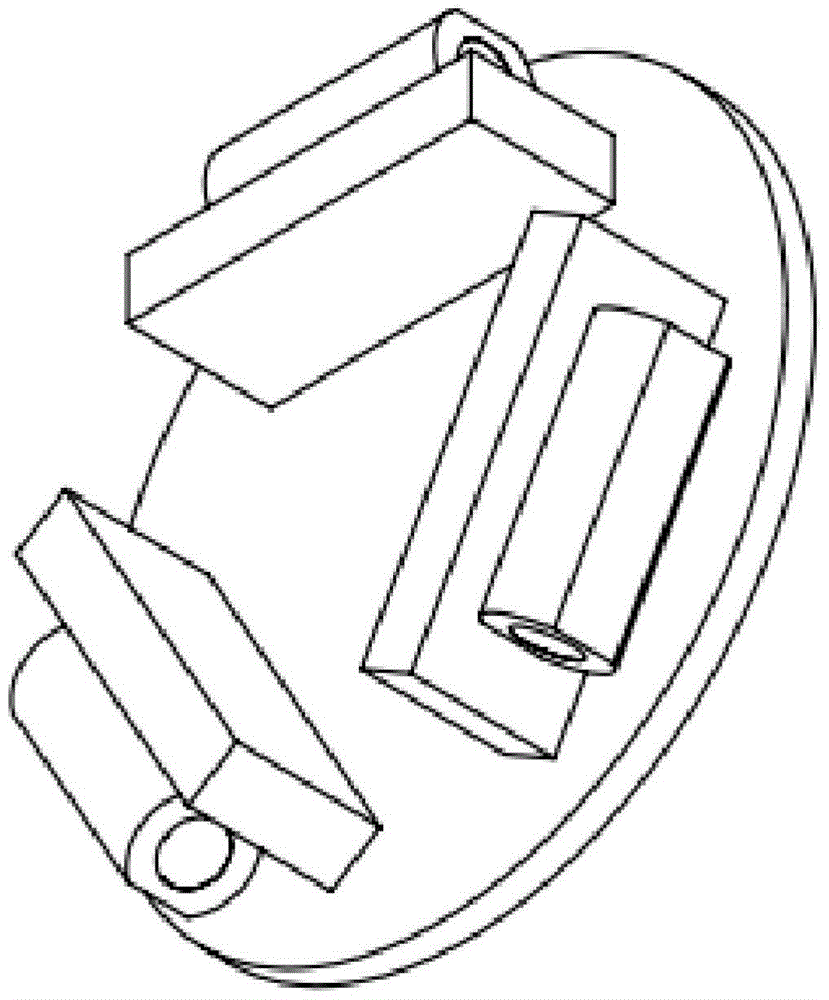

[0057] Such as Figure 6 , Figure 7 As shown, four rotating heads are fixedly installed on the rotating disc 21 . Others are the same as in Example 1.

[0058] The present invention uses a specially designed large-area uniform pump on the side, and under the same pump energy, reduces the energy density on the gain medium 17 per unit area, slows down the establishment of transient absorption of dye molecules, prolongs the life of solid dyes, and indirectly improves the output efficiency of the laser. The cooling device 18 is used to control the temperature of the solid dye gain medium to relieve heat accumulation in the solid dye gain medium 17 under high-energy pumping, prolong the life of the solid dye, and improve laser efficiency. For the side pumping method, the gain medium 17 is specially designed, and the inner layer is wrapped with a layer of gel sol glass without dye doping. Since the refractive index of the inner and outer layers is almost the same, better beam qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com