Master cylinder with flow restriction system

A technology of brake fluid and main pressure, used in brakes, brake transmissions, hydraulic brake transmissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

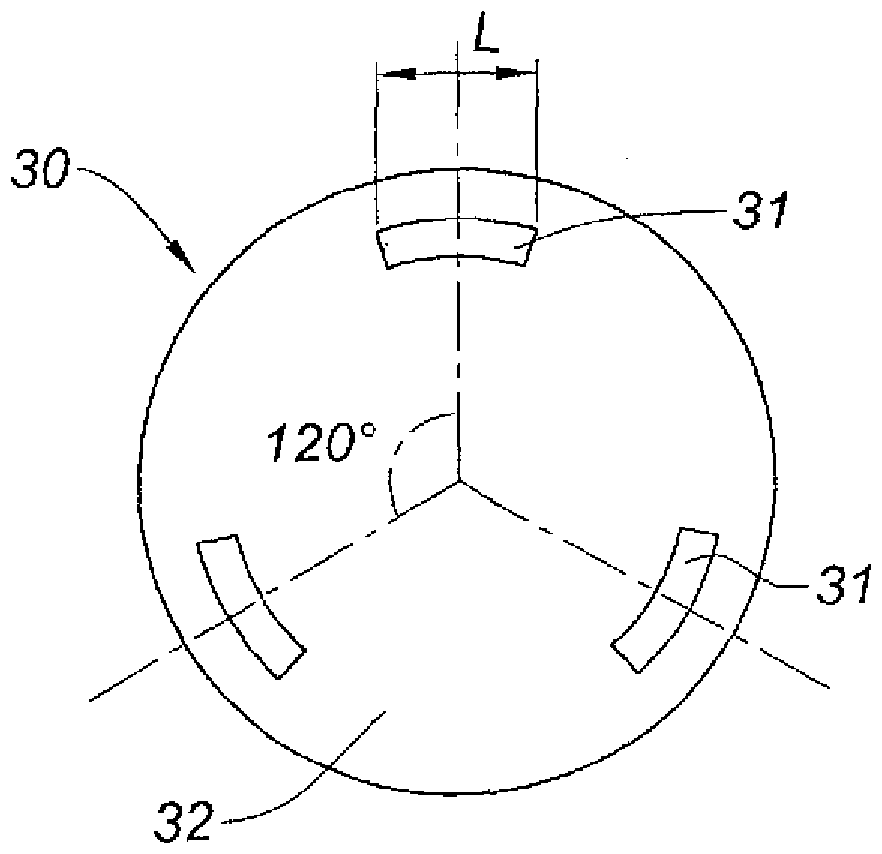

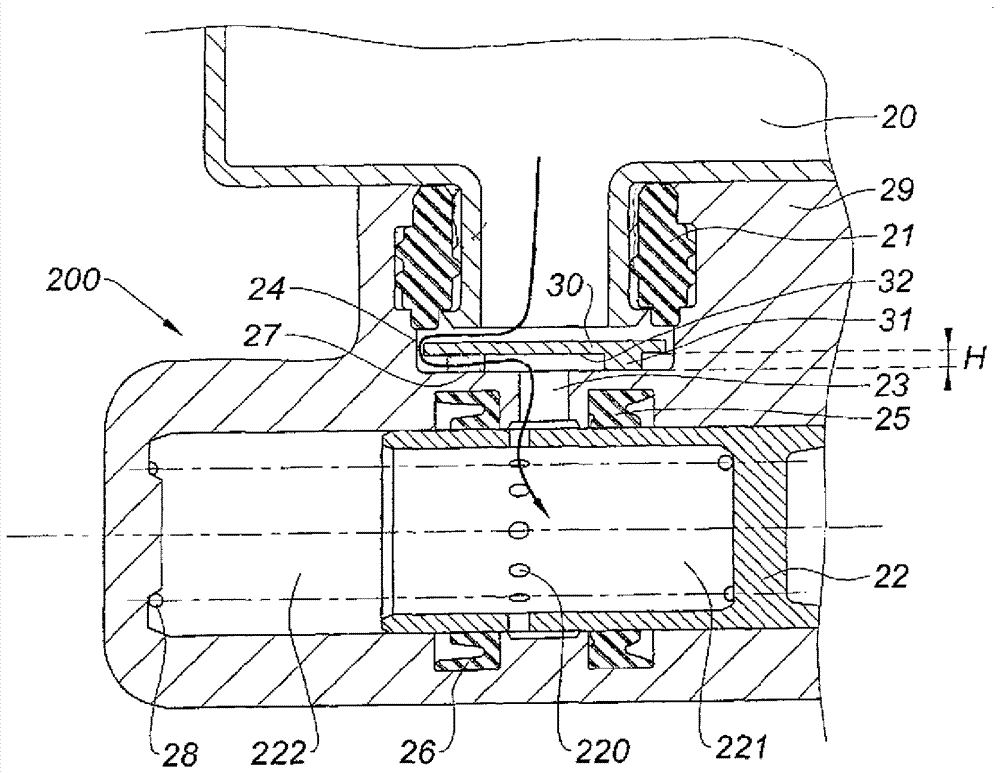

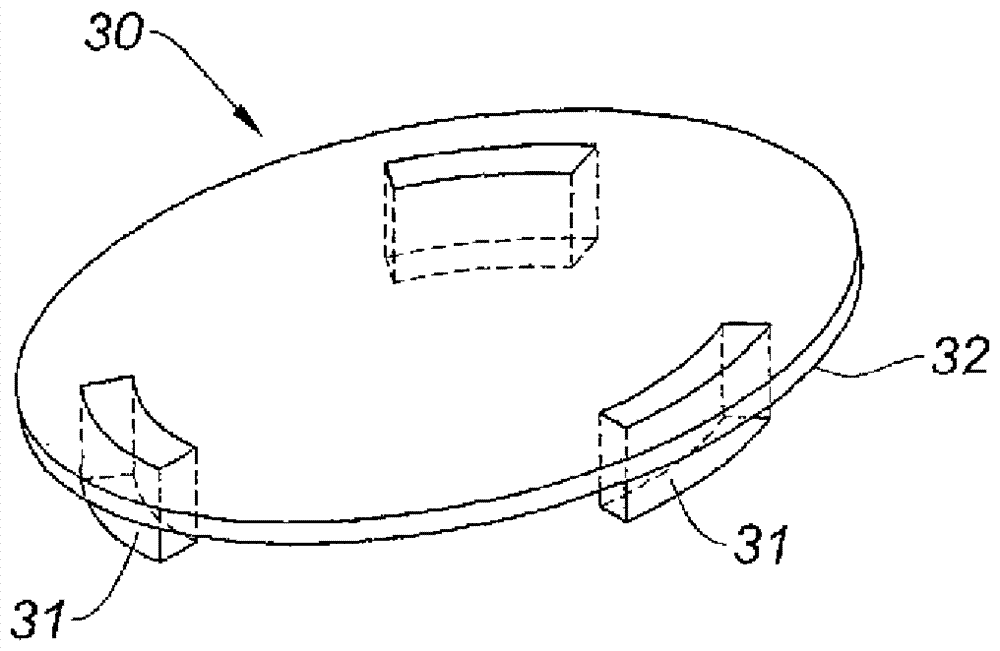

[0060] figure 1 The master brake cylinder 100 is shown with a bore 11 that receives the primary piston 2 , the secondary piston 3 and the primary spring 7 and secondary spring 8 . The function of the pistons 2, 3 is to bring the main pressure chamber 9 and the auxiliary pressure chamber 10 under pressure. The brake fluid supply inlets 12, 13 are used for connection with a brake fluid container (not shown). Two sides of the inlet hole 12 are provided with sealing covers 33 and 4 , and two sides of the inlet hole 13 are provided with sealing covers 5 and 6 . When the master cylinder is at rest, the master piston 2 is in figure 1 in the position shown. The walls of the pistons 2 , 3 provided with passages 14 , 15 communicate the perforations 12 , 13 with the interior of each piston 2 , 3 and with the primary 9 and secondary 8 pressure chambers. At rest, the sealing caps 4, 6 allow communication between the inlets 12, 13 and the main and auxiliary pressure chambers 9, 10, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com