Protected powder metal stator core and solenoid actuator using same

A stator core and solenoid technology, applied in the direction of magnetic core/yoke, engine components, machine/engine, etc., can solve problems such as corrosion, performance reduction, protective coating occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

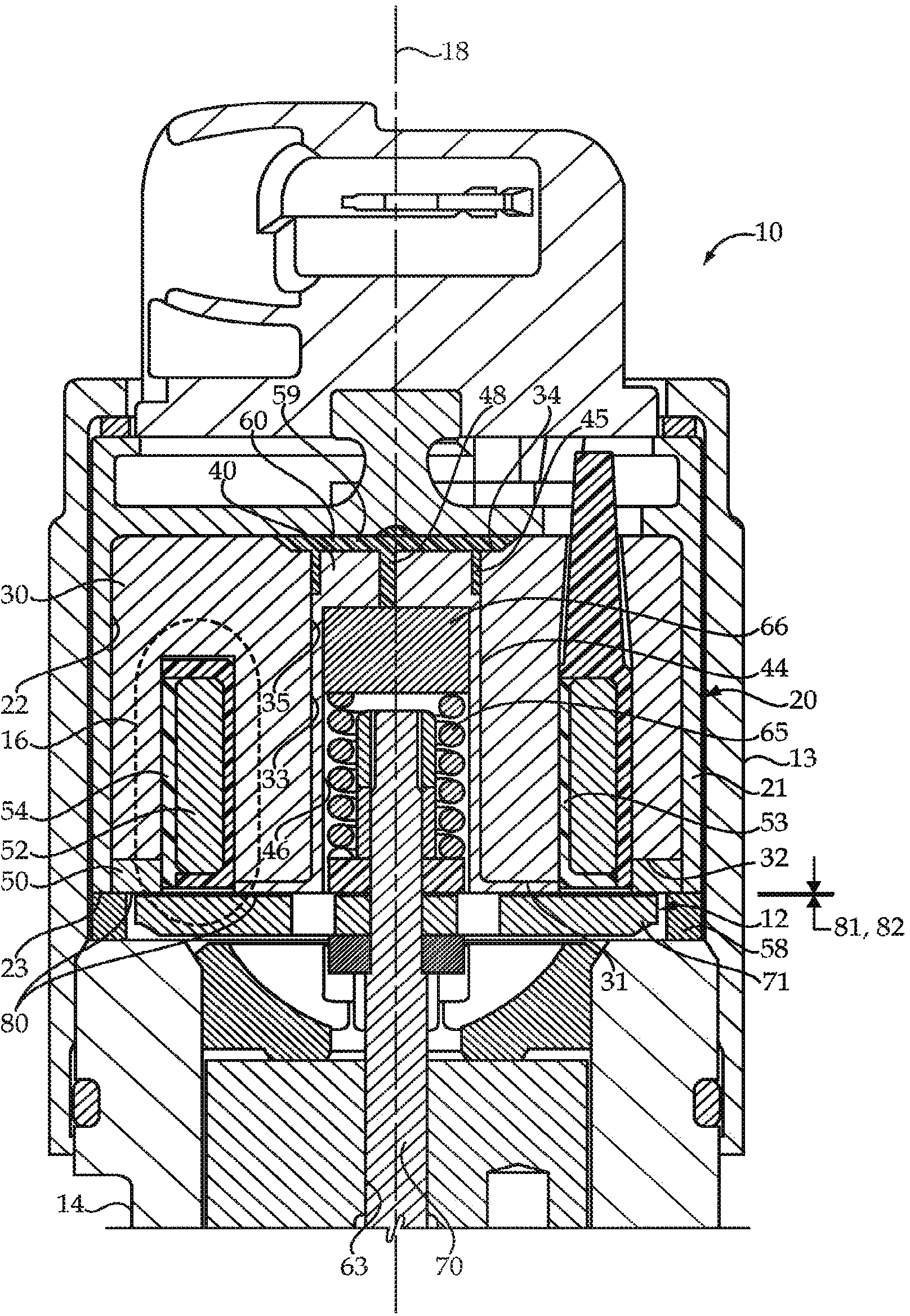

[0015] refer to figure 1 , a solenoid actuator 10 is shown as may be present in the upper half of a common rail fuel injector for an electronically controlled compression ignition engine. The solenoid actuator 10 includes a stator assembly 20 and an armature assembly 12 within an actuator housing 13 and body 14 . Armature assembly 12 is normally biased downwardly and away from stator assembly 20 by biasing spring 65 . When the coil 52 of the stator assembly 20 is energized, magnetic flux lines are generated around the coil 52 to attract the armature assembly 12 toward the stator assembly 20 . The armature assembly 12 moves from the initial air gap 81 towards the final air gap 82, and the travel distance corresponding to the distance between these two air gaps can be so small that at figure 1 almost invisible in view. Regardless, the armature assembly 12 does not contact the stator assembly throughout its travel from the initial air gap 81 towards the final air gap 82 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com