A combined tree hole cover and its application

A combined type and cover plate technology, which is applied in the direction of plant protection covers, etc., can solve the problems of easy deformation of the cover plate, poor flatness and stability, pollution of the environment, etc., and achieve reliable coverage, beautiful appearance and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described now in conjunction with accompanying drawing

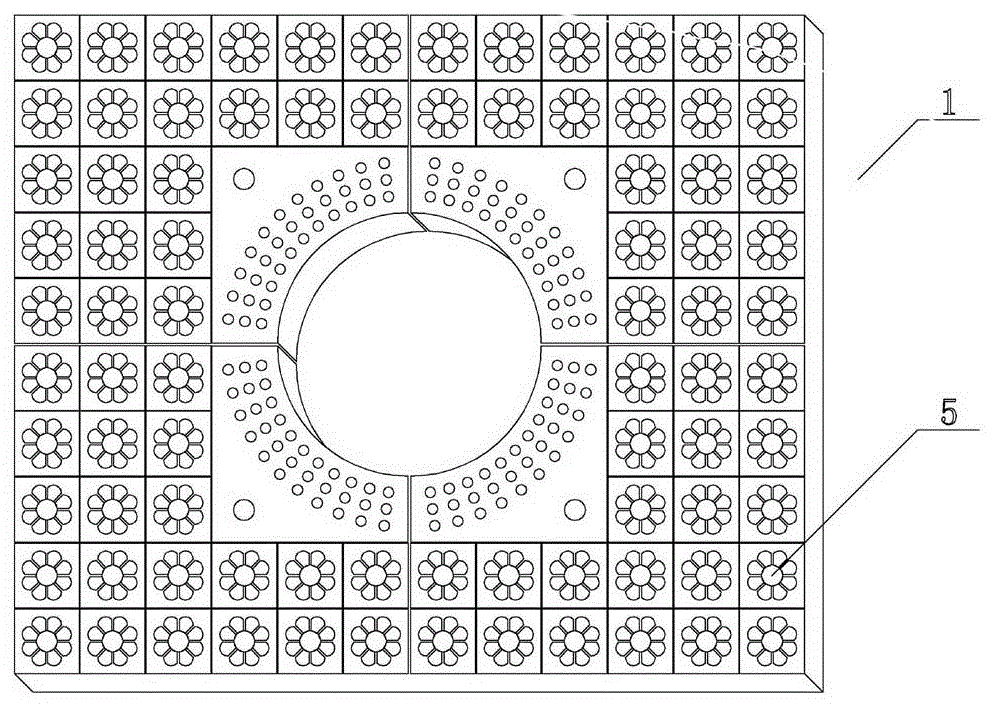

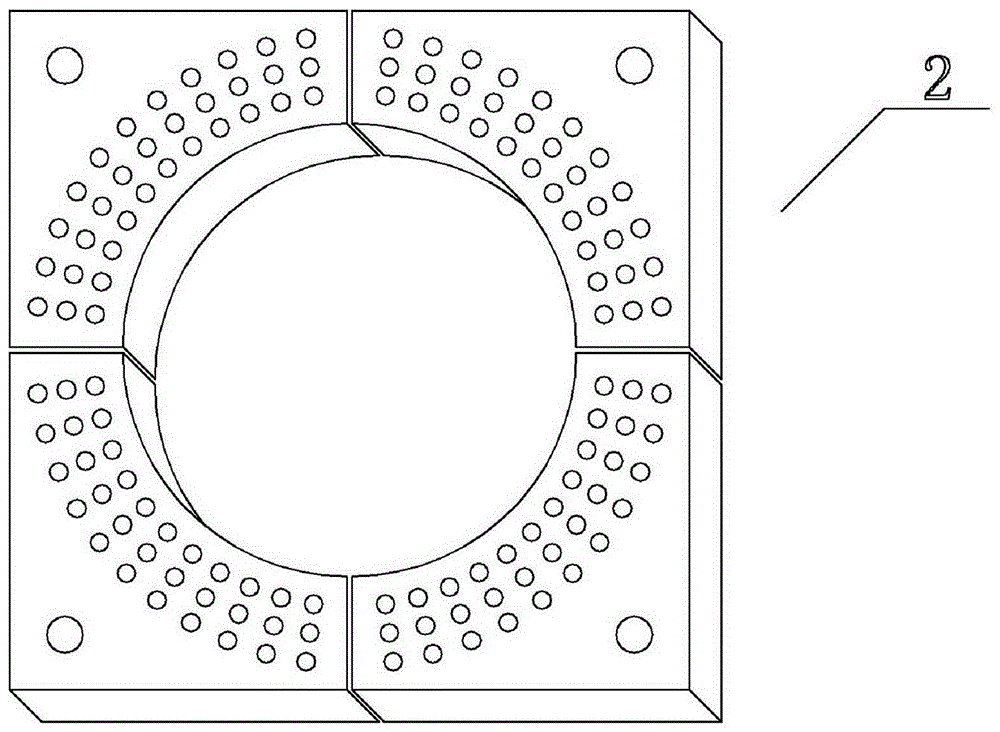

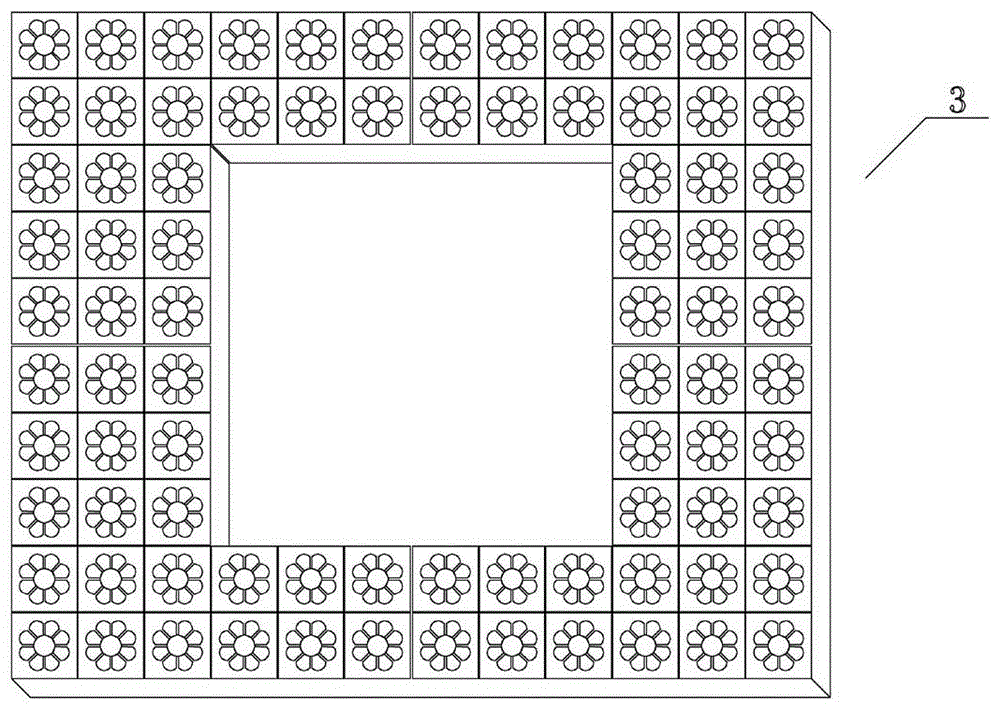

[0018] A combined tree hole cover, including a cover, is composed of: the combined tree hole cover 1 is composed of an adjustable cover 2 around the trunk and a peripheral adjustment cover 3, and can cover the floating soil around the trunk; The adjustable cover around the trunk is composed of four base plates 4 of the tree hole cover. The base 4 is a square plate with a pattern around it, and a perfect circle with a diameter of four small square sides is dug out in the center. , divided into four equal parts by cross cutting, leaving four squares remaining in the fan-shaped area of two small square side lengths at one corner; Its side length of decorative pattern is that the small square plate 5 that surrounds trunk adjustable cover plate 1 / 6th is long surrounds and forms.

[0019] The small square plate 5 with various decorative patterns is that there is a hollowed out ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com