Mud discharging device

The technology of a mud discharger and a mud discharge pipe is applied in the directions of chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc., and can solve the problems of increased use cost, short life, corrosion of mud discharge devices, etc. The effect of long service life and high sludge discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

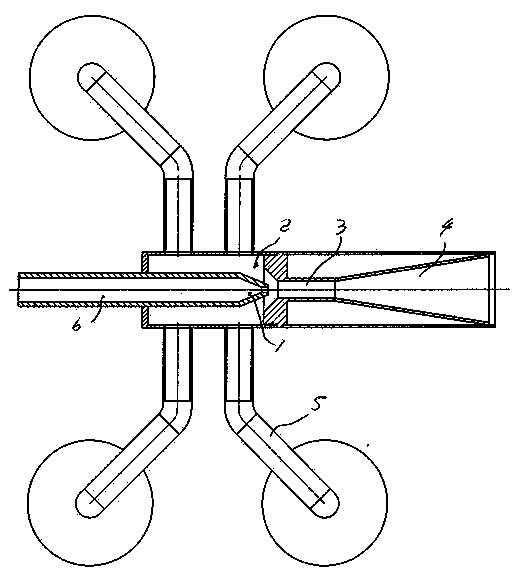

[0007] After analyzing and studying the structure of the existing utility model patent, the sludge, water and gas entering the mixing chamber are mixed and then discharged out of the tank through the diffusion tube. The mixing state of the above water, mud and gas in the diffusion tube is unstable, resulting in When the sludge is discharged more and sometimes less, the sewage discharge effect is not ideal. The present invention adopts the following technical scheme to make the mixing of water, mud and gas more uniform, that is, to add a stable section 3 of equal-diameter holes at the junction of the diffusion pipe and the mixing chamber, so that the water, mud and gas coming out of the mixing chamber After further stable mixing in the diameter hole section, it enters the diffusion section, and the water inlet pipe 6, nozzle 1, mixing chamber 2, diffusion section 4 and mud discharge pipe 5 are not changed. The mixing is more uniform and the sewage discharge effect is improved. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com