Wastewater purification apparatus

A technology of sewage purification and sewage treatment device, which is applied in water/sewage treatment, water/sludge/sewage treatment, feeding/discharging device of sedimentation tank, etc. The problems of parts burning and heavy operating box load can achieve the effect of convenient heat dissipation, increase service life, and solve the problem of easy blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

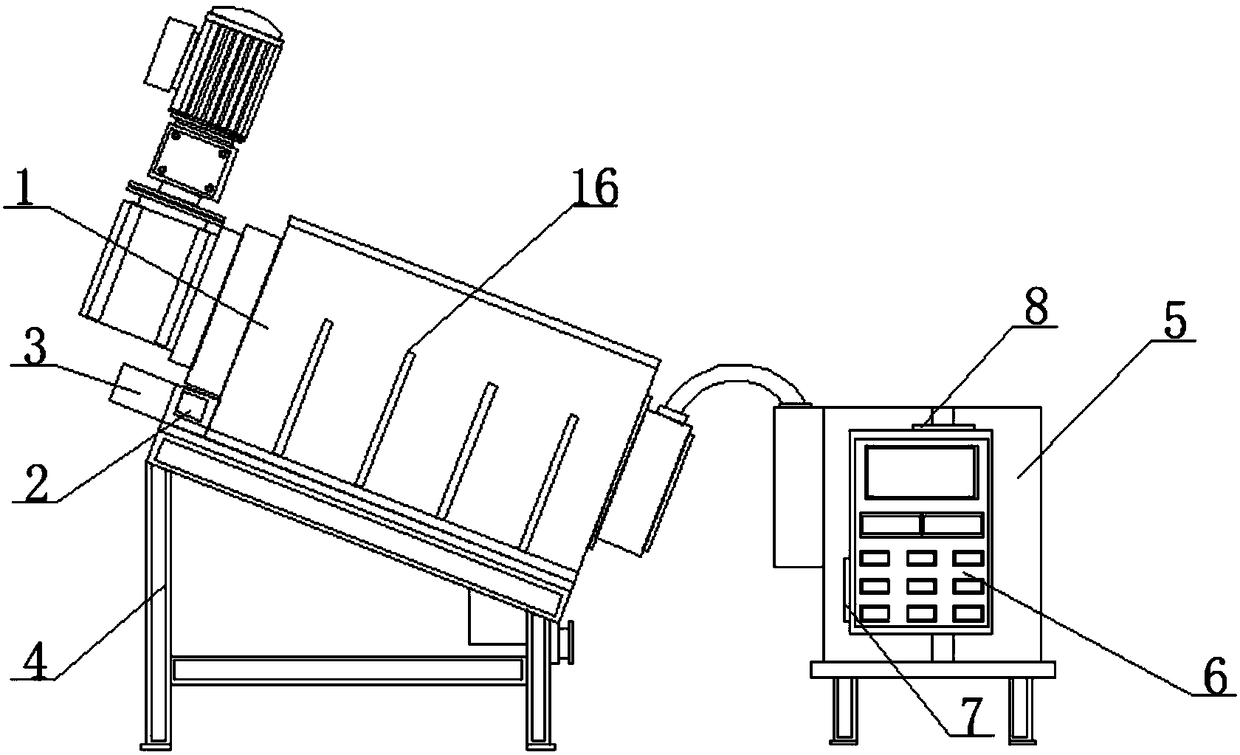

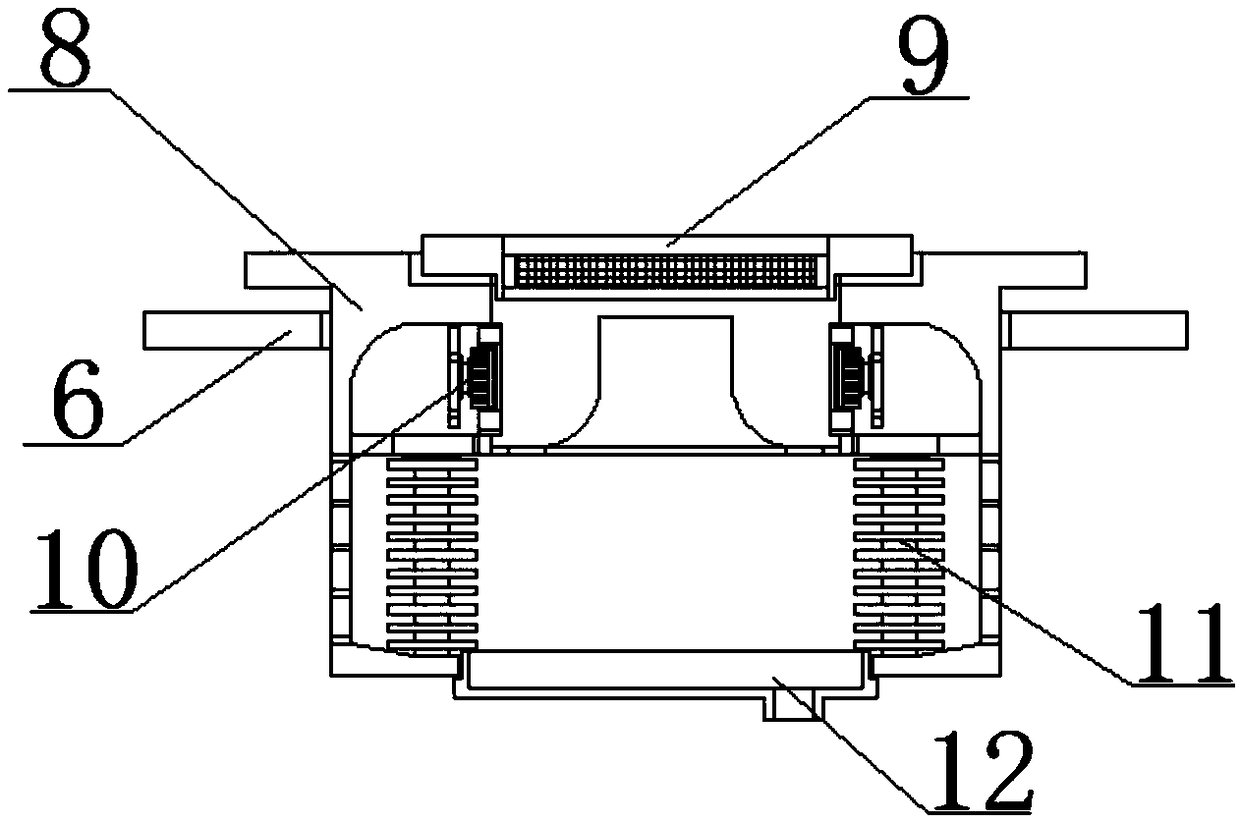

[0020] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution: a sewage purification device, including a sewage treatment device outer shell 16, and also includes a heat dissipation mechanism, one side of the sewage treatment device outer shell 16 is fixed with a screw dehydration box 1, and the screw dehydration box 1 One side is fixed with a mud outlet 2 by bolts, and the other side of the outer shell 16 of the sewage treatment device is fixed with an operation box 6 by bolts. The heat dissipation mechanism includes an air inlet 7, a heat dissipation load-bearing frame 8, a dustproof filter Fan 10, heat absorbing plate 11 and water receiving tray 12, the top of the operation box 6 is fixed with a heat dissipation load-bearing frame 8 by bolts, the bottom of the heat dissipation load bearing frame 8 is fixed with a water receiving tray 12 by screw threads, and the inner side of the heat dissipation load bearing frame 8 A heat-absorbing p...

Embodiment 2

[0024] see Figure 1-Figure 4 , the present invention provides a technical solution: a sewage purification device, including a sewage treatment device outer shell 16, and also includes a heat dissipation mechanism and a cleaning mechanism. One side of the sewage treatment device outer shell 16 is fixed with a screw dehydration box 1 by bolts, and the spiral dehydration One side of the box 1 is fixed with a mud outlet 2 by bolts, and the other side of the outer shell 16 of the sewage treatment device is fixed with an operation box 6 by bolts. The heat dissipation mechanism includes an air inlet 7, a heat dissipation load-bearing frame 8, and a dust filter. 9. Cooling fan 10, heat absorbing plate 11 and water receiving tray 12, the top of the operation box 6 is fixed with a heat dissipation load-bearing frame 8 by bolts, and the bottom of the heat dissipation load-bearing frame 8 is fixed with a water receiving tray 12 by screws, and the heat dissipation load-bearing frame The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com