Accurate positioning system of L-shaped edge-wrapped glass in die

A technology of wrapping glass and precise positioning, applied in the coating and other directions, can solve the problems of difficulty in guaranteeing the width of wrapping and printing, waste of raw materials in production, large positioning error, etc., so as to improve production efficiency, product yield and safety. The effect of good performance and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

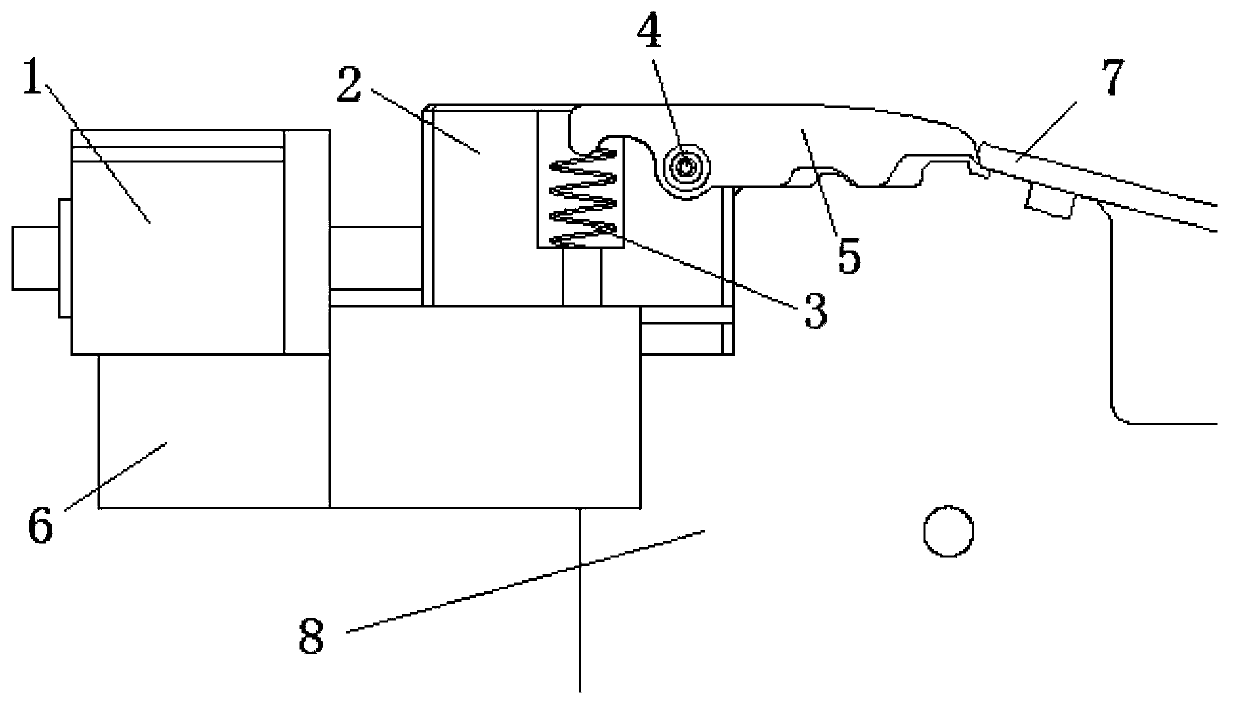

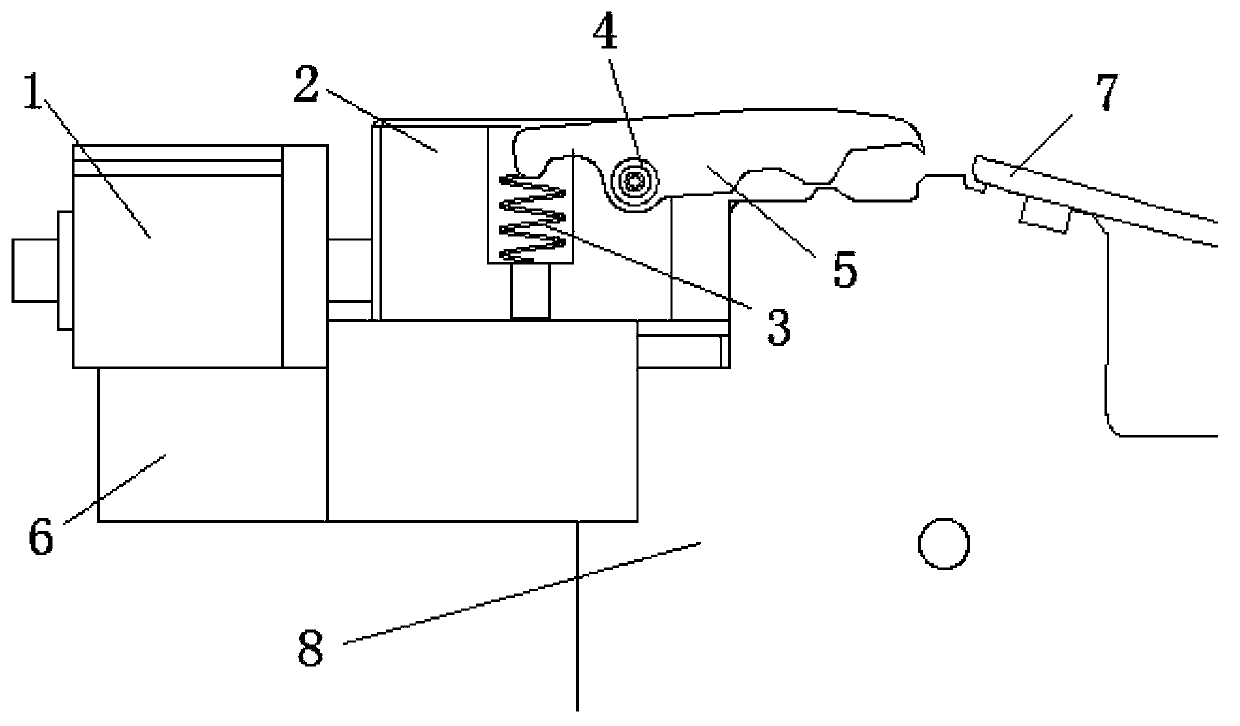

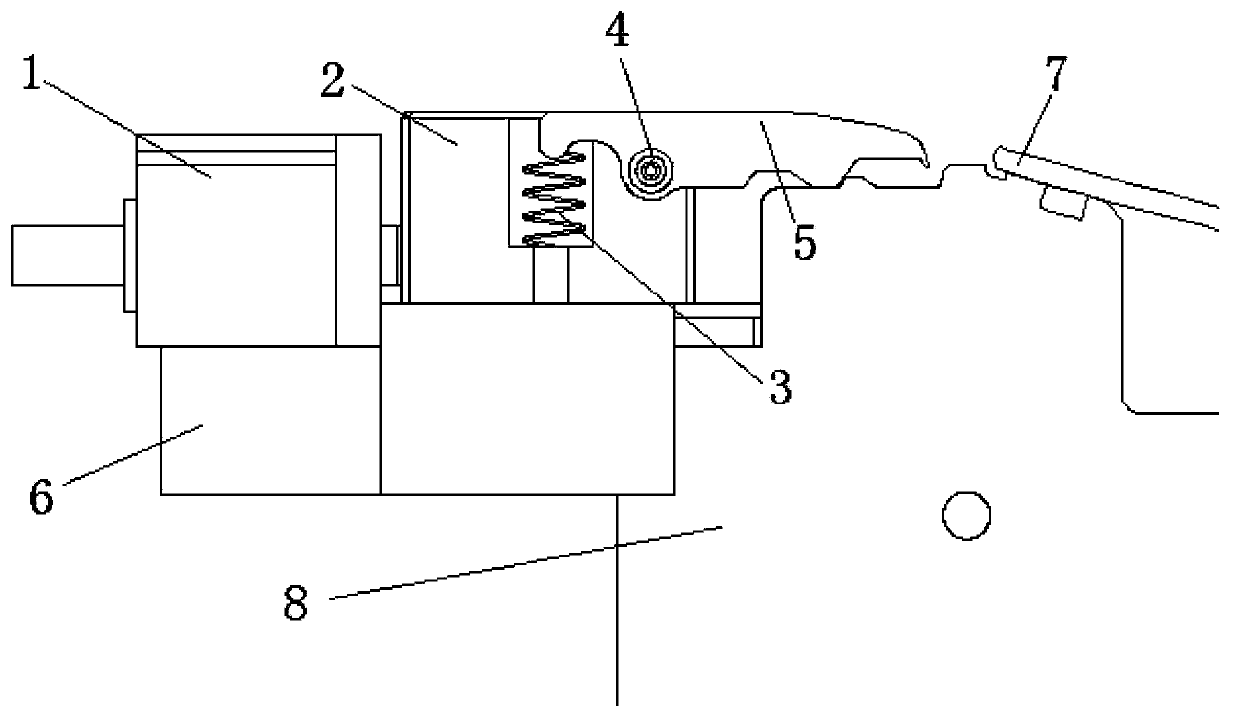

[0019] An accurate positioning system for L-shaped edged glass in the mold, its structure is as follows Figure 1-4 As shown, the positioning system is composed of a telescopic cylinder 1, a positioning claw support seat 2, a compression spring 3, a connecting pin 4, a positioning claw 5 and a cylinder support seat 6. The telescopic cylinder 1 is arranged on the cylinder support seat 6, and the positioning claw 5 is connected with the front part of the telescopic cylinder 1 through the positioning claw support seat 2. tail end. The positioning claw 5 is movably connected on the positioning claw support seat 2 through the connecting pin 4, so that the positioning claw 5 can rotate around the connecting pin 4. In addition, the tail end of the positioning claw 5 is supported by the compression spring 3 to make the front end of the positioning claw 5 tight. Paste the mold7. The positioning claw 5 is provided with a wave shape, which matches with the shape of the upper surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com